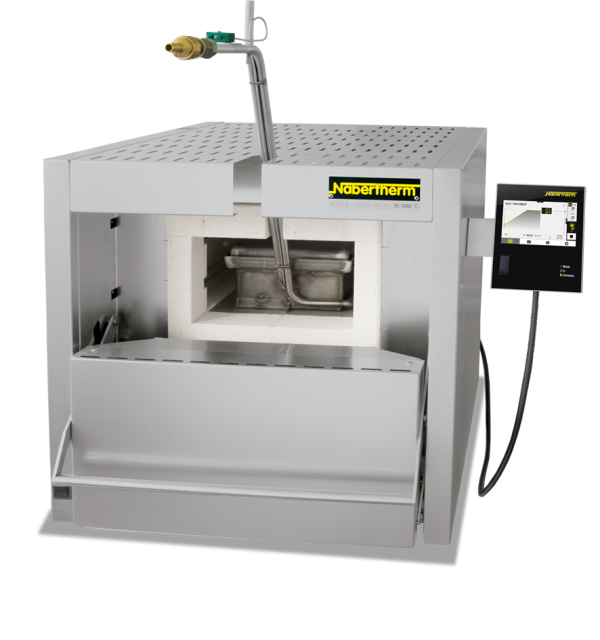

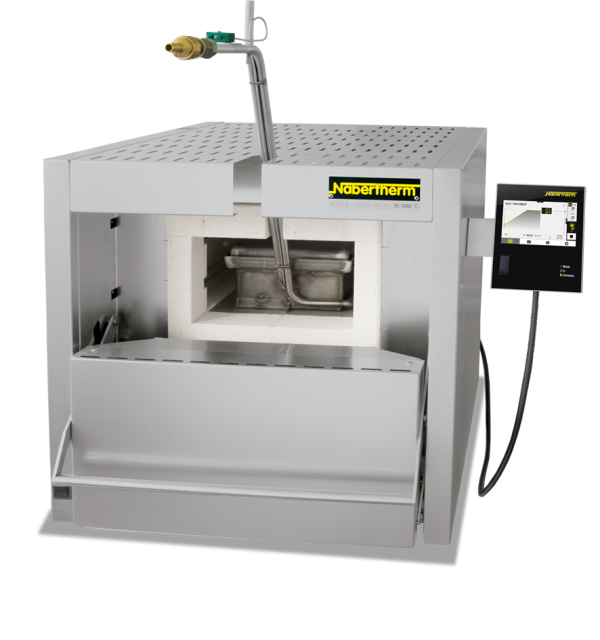

Chamber Furnaces N ../H

Heating elements on support tubes ensure free heat radiation and a long service life.

Heating elements on support tubes ensure free heat radiation and a long service life.

Chamber furnace Systems N 7/H - N 17/HR with their low but deep furnace chamber are particularly suitable for smaller batches. The process in these furnaces can be carried out exactly as in the chamber furnace systems LH 15/12 - LH 60/12.

| Model | Tmax | Inner dimensions protective gas box in mm | Outer dimensions in mm3 |

Process flush rate | Connected load | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | W | D | H | l/min | kW | connection | in kg | in min2 | |

| N 7/H System | 1150 | 180 | 190 | 90 | 800 | 650 | 600 | 5 - 8 | 3.0 | 1-phase | 60 | 320 |

| N 11/H System | 1150 | 180 | 290 | 90 | 800 | 750 | 600 | 5 - 8 | 3.5 | 1-phase | 70 | 320 |

| N 11/HR System | 1150 | 180 | 290 | 90 | 800 | 750 | 600 | 5 - 8 | 5.5 | 3-phase1 | 70 | 70 |

| N 17/HR System | 1150 | 180 | 440 | 90 | 800 | 900 | 600 | 5 - 8 | 6.4 | 3-phase1 | 90 | 110 |

| 1Heating only between two phases 2Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE rsp. 400 V 3/N/PE) 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

||||||||||||

A complete overview of our extensive range of sintering and preheating furnaces and accessories for the dental sector can be found in our “Dental” catalog.

We look forward to receiving your inquiry!