Forced Convection Chamber Furnaces up to 675 Liter Electrically Heated

Dzięki modułowej konstrukcji tych pieców można je dostosować do indywidualnych wymagań procesu za pomocą odpowiedniego osprzętu.

Funkcja i wyposażenie

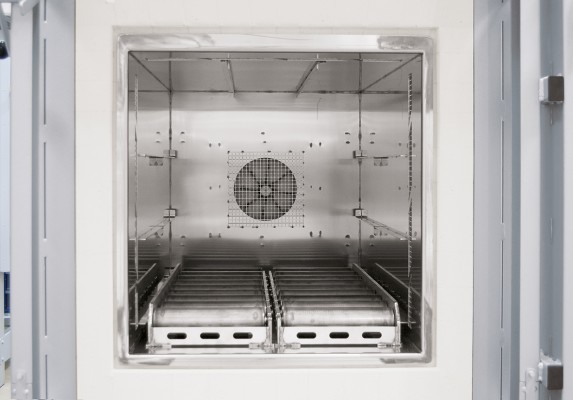

The very good temperature uniformity of these chamber furnace with air circulation provides for ideal process conditiones for annealing, curing, solution annealing, artificial ageing, sintering of PTFE, preheating, or soft annealing and brazing. The forced convection chamber furnaces are equipped with a suitable annealing box for soft annealing of copper or tempering of titanium, and also for annealing of steel under non-flammable protective or reaction gases. The modular forced convection chamber furnace design allows for adaptation to specific process requirements with appropriate accessories.

- Tmax 450 °C, 650 °C, or 850 °C

- Horizontal air circulation with optimum distribution through stainless steel baffles

- Swing door hinged on the right side

- Base frame included in the delivery

- Temperature uniformity up to +/− 4 °C according to DIN 17052-1

- Optimum air distribution enabled by high flow speeds

- One frame sheet and rails for two additional trays included in the scope of delivery

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500 (5 programs with 4 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Dodatkowe wyposażenie

Additional Equipment for Models up to 450 °C

- Air inlet and exhaust air flaps when used for drying

- Controlled cooling via controlled flap and fan

- Additional frame sheet

- Gas supply boxes for different charging methods

- Gas feed fittings

- Charge control with documentation of the charge thermocouple

- Signal tower

- Charging systems

- Process control and documentation via VCD software package for monitoring, documentation and control

Further Additional Equipment for Models up to 850 °C

- Optimization of the temperature uniformity up to +/− 3 °C according to DIN 17052-1

- Measuring frames and thermocouples for TUS measurements charge or comparative measurements

- Version according to AMS2750G or CQI-9

- Manual lift door (up to model NA 120/..)

- Pneumatic lift door

- Manual roller conveyor in furnace chamber for high charge weights

- Process control and documentation via VCD software package for monitoring, documentation and control

Specyfikacja techniczna

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating | Electrical | Weight | Heat-up time3 | Cool-down time3 from Tmax | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| power | to Tmax | to 150 °C in minutes | ||||||||||||

| °C | w | d | h | in l | W | D | H | in kW2 | connection | in kg | in minutes | Flaps4 | Fan cooling4 | |

| NA 120/45 | 450 | 450 | 600 | 450 | 120 | 1250 | 1550 | 1550 | 9.0 | 3-phase | 460 | 60 | 240 | 30 |

| NA 250/45 | 450 | 600 | 750 | 600 | 250 | 1350 | 1650 | 1725 | 12.0 | 3-phase | 590 | 60 | 120 | 30 |

| NA 500/45 | 450 | 750 | 1000 | 750 | 500 | 1550 | 1900 | 1820 | 18.0 | 3-phase | 750 | 60 | 240 | 30 |

| NA 60/65 | 650 | 350 | 500 | 350 | 60 | 910 | 1390 | 1475 | 9.0 | 3-phase | 350 | 120 | 270 | 60 |

| NA 120/65 | 650 | 450 | 600 | 450 | 120 | 990 | 1470 | 1550 | 12.0 | 3-phase | 460 | 60 | 300 | 60 |

| NA 250/65 | 650 | 600 | 750 | 600 | 250 | 1170 | 1650 | 1680 | 20.0 | 3-phase | 590 | 90 | 270 | 60 |

| NA 500/65 | 650 | 750 | 1000 | 750 | 500 | 1290 | 1890 | 1825 | 27.0 | 3-phase | 750 | 60 | 240 | 60 |

| NA 60/85 | 850 | 350 | 500 | 350 | 60 | 790 | 1330 | 1440 | 9.0 | 3-phase | 315 | 150 | 900 | 120 |

| NA 120/85 | 850 | 450 | 600 | 450 | 120 | 890 | 1420 | 1540 | 12.0 | 3-phase | 390 | 150 | 900 | 120 |

| NA 250/85 | 850 | 600 | 750 | 600 | 250 | 1120 | 1690 | 1810 | 20.0 | 3-phase | 840 | 180 | 900 | 180 |

| NA 500/85 | 850 | 750 | 1000 | 750 | 500 | 1270 | 1940 | 1960 | 30.0 | 3-phase | 1150 | 180 | 900 | 210 |

| NA 675/85 | 850 | 750 | 1200 | 750 | 675 | 1270 | 2190 | 1960 | 30.0 | 3-phase | 1350 | 210 | 900 | 210 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher 3Approx. information in empty furnace 4Additional equipment |

||||||||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców, szaf suszarniczych i akcesoriów do pomieszczeń laboratoryjnych można znaleźć w naszym katalogu „Laboratorium”.