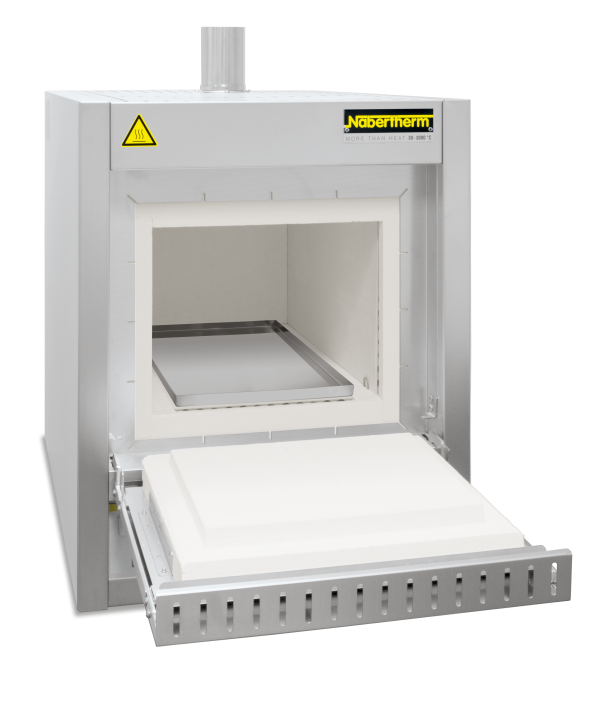

The chamber furnaces of the model series N(B) .. BO are used for processes with large amounts of organic matters or high vaporization rates. These models can be used for products which are insensitive against temporarily uncontrolled temperature increases. Processes in which the product or contaminations on the product are ashed by ignition can be also carried out safely in this type of chamber furnace. Examples include residual wax removal of pouring clustersfollowed by sintering, or thermal cleaning of oxide catalytic honey combs from soot or fuel residues. The electrically heated N...BO furnaces can be used for processes with exact temperature control and uniformity. For safety reasons, they are equipped with an integrated gas torch for igniting the flammable components in the gas mixture. The accumulation of flammable components is avoided and their safe combustion is ensured.

The gas-fired NB…BO furnaces are designed for processes which require a heat-up time to temperatures > 500 °C

The burning of unwanted organic ingrediants can take place at temperatures > 500 °C. Following this, a subsequent process can take place up to max. 1400 °C (electrically) or up to 1000 °C (gas-fired).

For safety, the furnace door locks after the program was started and cannot be opened again until the temperature has dropped below a defined value. In case of burner malfunction or gas shortage the process is aborted.

Chamber furnaces N 100 BO - N 650/14 BO, electrically heated and gas-fired ignition flame

- Tmax 1000 °C or 1400 °C

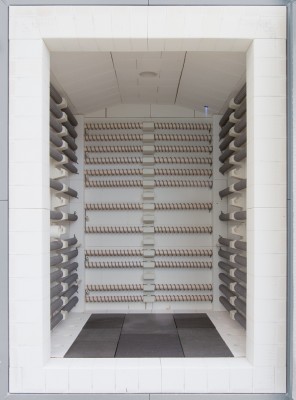

- Standard sizes up to 650 liters furnace chamber, additional sizes on request

- Exhaust hood

- Fully automatic temperature control

- Optional thermal afterburning

- Ignition flame using natural gas or liquid gas (LPG)

- Defined application within the constraints of the operating instructions

Chamber furnaces models NB 300 BO and NB 650 BO, gas-fired

- Tmax 1000 °C

- Standard sizes up to 650 liters furnace chamber, additional sizes on request

- Integrated thermal afterburning

- Gas burners operating with natural gas or liquid gas (LPG)

- Defined application within the constraints of the operating instructions