機能と設備

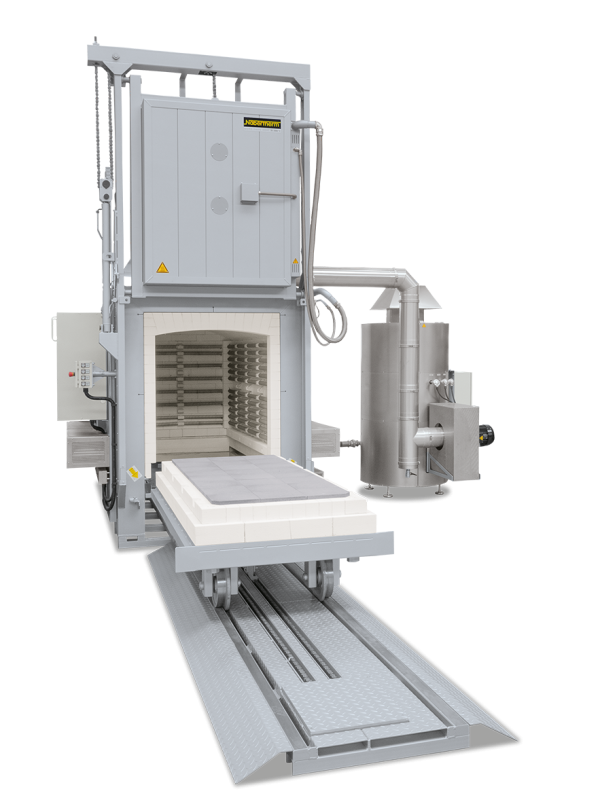

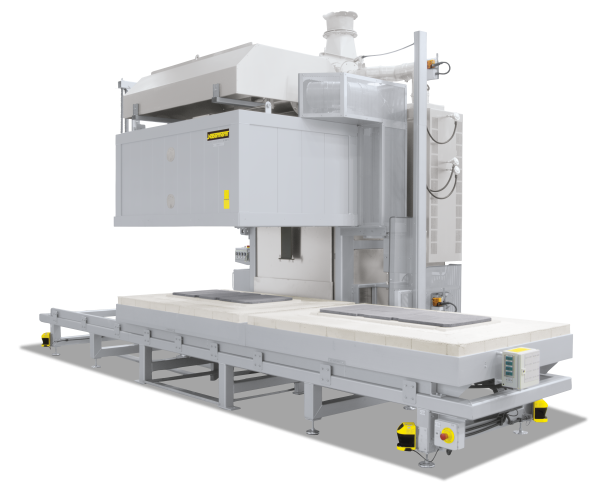

These top hat furnaces or bottom loading furnaces were specially developed for tempering quartz glass, cooling complex structures or when the process requires the treatment of warm glass, e. g., the welding process in glass apparatus manufacturing. The wide-opening electro-hydraulically driven top hat allows furnace opening even at high temperatures and provides easy access from 3 sides. Depending on process conditions, a top hat or bottom loading version is advisable. The system can be expanded to include one or more changeable tables, either manually or motorized. Further additional equipment like a multi-zone control to optimize the temperature uniformity or controlled cooling systems for shorter processes provide for customized solution with respect to the process requirements.

- Tmax 1280 °C

- Dual shell housing with rear ventilation, provides for low shell temperatures

- Top hat furnaces (model LT): electrohydraulically driven top hat with fixed table

- Bottom loading furnaces (model LB): driven table and fixed top hat

- Five-sided heating from all four sides and from the table provides for a temperature uniformity up to +/− 10 °C according to DIN 17052-1

- Heating elements mounted on support tubes provide for free radiation and long service life of the heating wire

- Bottom heating protected by SiC tiles which provide for a level stacking surface

- Multi-layer insulation consisting of lightweight refractory bricks backed by special insulation

- Long-life ceiling design with fiber insulation

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Automatic exhaust air flap on the furnace roof

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller P570 (50 programs with each 40 segments)

付加装置

- Tmax to 1400 °C

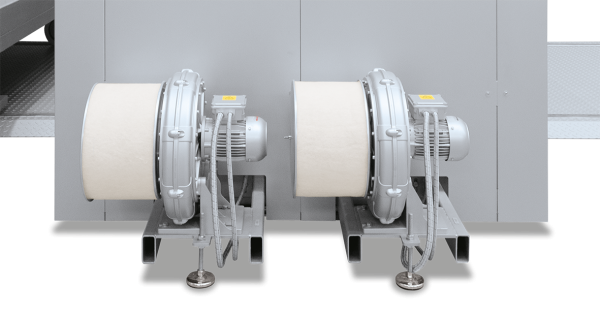

- Cooling system with fresh air fan for rapid cooling

- Sides with fiber insulation to reduce cycle times

- Fabric cover on the fiber roof (and sides) to reduce fiber dust

- Protective gas connection for purging the furnace with non-flammable protective or reaction gases

- Automatic gas supply systems

- Multi-zone control adapted to the particular furnace provides model for optimal temperature uniformity

- Commissioning of the furnace with test firing and temperature uniformity measurement (also with load) for the purpose of process optimization

- Additional tables, table changing system, also motorized

- Exhaust air and exhaust gas piping

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

技術仕様

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating power in | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | kW2 | connection | in kg | |

| H 125/LB, LT | 1280 | 800 | 400 | 400 | 125 | 1550 | 1500 | 2200 | 12 | 3-phase | 1250 |

| H 250/LB, LT | 1280 | 1000 | 500 | 500 | 250 | 1530 | 1700 | 2300 | 18 | 3-phase | 1400 |

| H 500/LB, LT | 1280 | 1200 | 600 | 600 | 500 | 2020 | 1800 | 2500 | 36 | 3-phase | 1800 |

| H 1000/LB, LT | 1280 | 1600 | 800 | 800 | 1000 | 2200 | 2000 | 2900 | 48 | 3-phase | 2800 |

| H 1350/LB, LT | 1280 | 2800 | 620 | 780 | 1360 | 3750 | 2050 | 3050 | 75 | 3-phase | 3500 |

| H 3000/LB, LT | 1280 | 3000 | 1000 | 1000 | 3000 | 4000 | 2100 | 3200 | 140 | 3-phase | 6200 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher |

|||||||||||