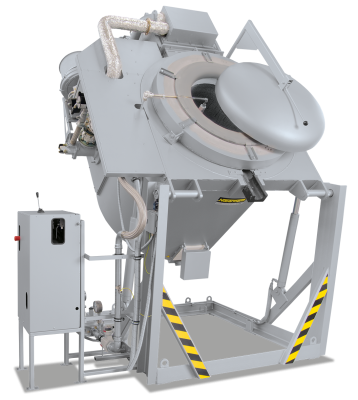

The gas-fired tilting furnaces with recuperative burner provide for optimum energy utilization combined with very high melt quality. Fitted with a burner system including heat-recovery system the energy efficiency of gas-fired tilting furnaces with the side exhaust gas discharge is significantly improved.

Depending on utilization the exhaust gases from the crucible furnace are guided through a heat exchanger in order to preheat the combustion air for the burner. The system provides for energy savings of up to 25 % compared to conventional gas-fired tilting furnaces with side exhaust gas discharge. The higher purchase costs are amortized within a short time.

The KBR series is recommended when both high melt quality requirements and high energy efficiency are required, and the speed of the melting process is of secondary interest. If the fastest possible melting rate is important for the process and a particularly high quality of the melt is of secondary importance, a conventional tilting furnace KB with exhaust ducting over the edge of the crucible is recommended.

Standard Equipment as KB Models, but

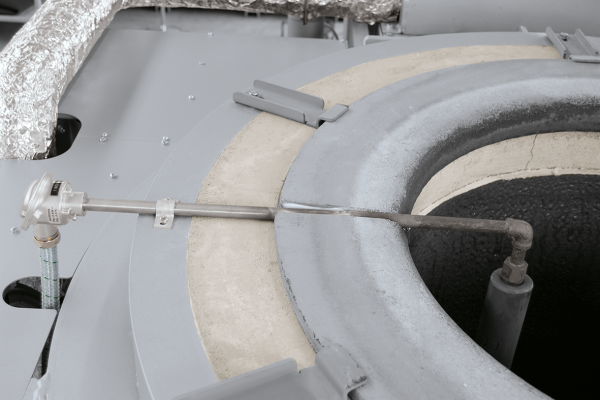

- Heat exchanger in the exhaust gas duct to preheat the combustion air for the burners

- Energy savings of up to 25 % in comparison to other gas-fired melting furnaces featuring side-wall exhaust gas vents

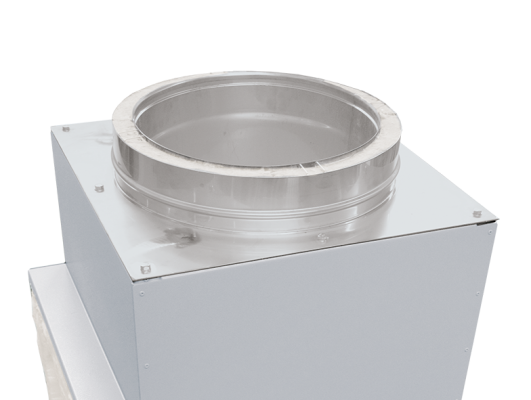

- Side exhaust gas discharge

- Low burn-off provides for high quality melt

- Low hydrogen absorption by the melt

- Low heat exposure for the operator in the area above the crucible

- Max. furnace temperature of 1100 °C for melt bath temperatures up to 950 °C

- Required minimum gas pressure at full load: 80 mbar

- Defined application within the constraints of the operating instructions