The gas-fired bale-out furnaces of the TB product lines provide for high melting performance. The use of modern burner systems, optimized pressures and flame guide in the furnace as well as the processing of high-quality insulation materials result in very low energy consumption.

Standard Equipment for all Bale-Out Furnaces

- TB ../12 for aluminum and zinc alloys

- TB ../14 for copper alloys such as bronze or brass

- Modern and powerful two-stage burner for high melting capacity and low maintenance operation

- Multi-layer insulation for optimum energy efficiency and low external wall temperatures

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

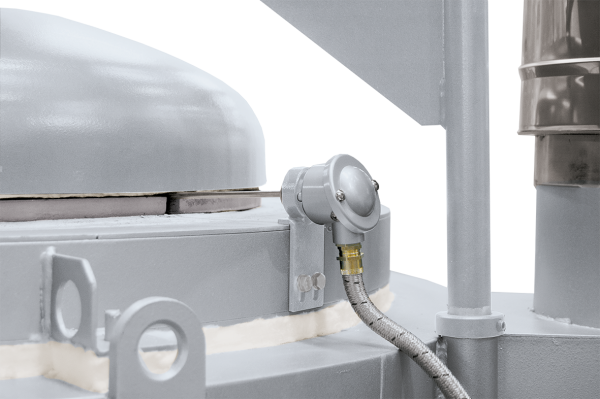

- Emergency outlet for safe discharge of the melt in case of a crucible break

- Integrated safety system which continues to operate the furnace at reduced power in case of malfunction in the thermocouple, in order to prevent the freezing of the melt

- Over-temperature limiter in furnace chamber for protection against overheating. The limiter switches the heating off when the set limit temperature is reached, and only switches it back on after the temperature has fallen again.

- Low-maintenance furnace chamber control with temperature measurement behind the crucible

- Defined application within the constraints of the operating instructions

Standard Equipment for Bale-Out Furnaces TB ../12

- Side exhaust gas discharge results in a high quality of the melt

- Swing lid

Standard Equipment for Bale-Out Furnaces TB ../14

- Insulation with an additional wear-and-tear layer made of copper-resistant refractory concrete

- Exhaust gas discharge over the crucible edge provides for high melting capacity

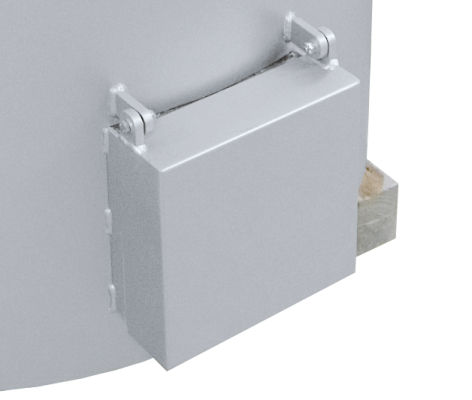

- Swinging collar plate for crucible pulling for bale-out furnaces to TB 10/14 - TB 20/14 (not possible for larger models)