功能与设备

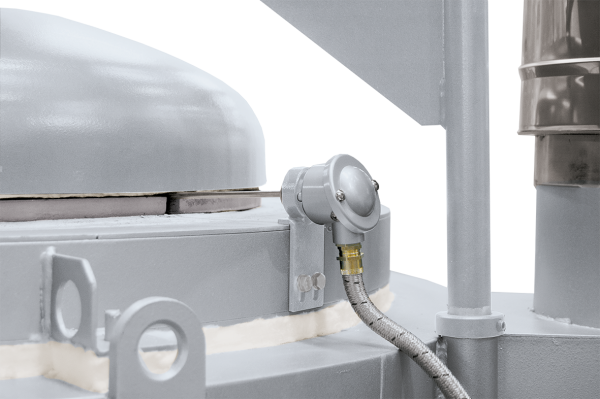

TB 20/14 型坩埚炉

舀出式炉TB 20/14,用于青铜熔化,带有侧面废气排放装置和旋转环板,用于拉动坩埚

Bale-out furnace TB 20/14 in a pit with exhaust gas discharge over the crucible rime and swiveling collar plate for crucible pulling

用于熔池温控的热电偶

紧急出口用于在发生坩埚破裂时安全地排放熔液

Bale-out furnace TB 240/12 with lateral exhaust gas discharge

The gas-fired bale-out furnaces of the TB product lines provide for high melting performance. The use of modern burner systems, optimized pressures and flame guide in the furnace as well as the processing of high-quality insulation materials result in very low energy consumption.

Standard Equipment for all Bale-Out Furnaces

- TB ../12 for aluminum and zinc alloys

- TB ../14 for copper alloys such as bronze or brass

- Modern and powerful two-stage burner for high melting capacity and low maintenance operation

- Multi-layer insulation for optimum energy efficiency and low external wall temperatures

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

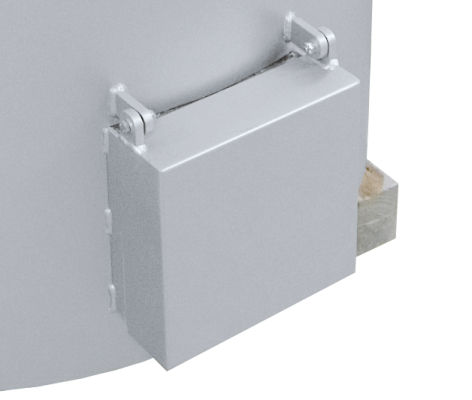

- Emergency outlet for safe discharge of the melt in case of a crucible break

- Integrated safety system which continues to operate the furnace at reduced power in case of malfunction in the thermocouple, in order to prevent the freezing of the melt

- Over-temperature limiter in furnace chamber for protection against overheating. The limiter switches the heating off when the set limit temperature is reached, and only switches it back on after the temperature has fallen again.

- Low-maintenance furnace chamber control with temperature measurement behind the crucible

- Defined application within the constraints of the operating instructions

Standard Equipment for Bale-Out Furnaces TB ../12

- Side exhaust gas discharge results in a high quality of the melt

- Swing lid

Standard Equipment for Bale-Out Furnaces TB ../14

- Insulation with an additional wear-and-tear layer made of copper-resistant refractory concrete

- Exhaust gas discharge over the crucible edge provides for high melting capacity

- Swinging collar plate for crucible pulling for bale-out furnaces to TB 10/14 - TB 20/14 (not possible for larger models)

附加设备

Additional Equipment for Bale-Out Furnaces TB ../12

- Crucible breakage monitoring with optical and acoustic signal

- SMS-alarm message in case of crucible breakage

- Bath control system

技术指标

| Model | Tmax furnace |

Tmax melt bath |

Crucible | Capacity in kg |

Burner output |

Melting performance3,5 | Consumption melting5 |

Consumption holding |

Outer dimensions4 in mm |

Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in kg/h | kWh/kg | kWh/h | ||||||||||||

| °C | °C | Al | Zn | Cu | kW | Al | Al | Lid closed | W | D | H | in kg | ||

| TB 80/12 | 1200 | 1050 | BU 200 | 200 | 520 | - | 180 | 1401 | 1.3 - 1.51 | 10 | 1200 | 1870 | 1240 | 900 |

| TB 100/12 | 1200 | 1050 | BU 250 | 250 | 660 | - | 180 | 1401 | 1.3 - 1.51 | 11 | 1310 | 1980 | 1380 | 1000 |

| TB 110/12 | 1200 | 1050 | BU 300 | 300 | 790 | - | 210 | 1501 | 1.3 - 1.51 | 13 | 1310 | 1980 | 1510 | 1200 |

| TB 150/12 | 1200 | 1050 | BU 350 | 350 | 920 | - | 300 | 2201 | 1.3 - 1.51 | 15 | 1310 | 1980 | 1550 | 1400 |

| TB 180/12 | 1200 | 1050 | BU 500 | 500 | 1320 | - | 300 | 2701 | 1.3 - 1.51 | 17 | 1450 | 2140 | 1560 | 1700 |

| TB 240/12 | 1200 | 1050 | BU 600 | 600 | 1580 | - | 390 | 3301 | 1.3 - 1.51 | 19 | 1490 | 2180 | 1700 | 1900 |

| TB 360/12 | 1200 | 1050 | BN 800 | 800 | 2110 | - | 400 | 3501 | 1.3 - 1.51 | 20 | 1590 | 2280 | 1800 | 2000 |

| TB 400/12 | 1200 | 1050 | BN 900 | 900 | 2370 | - | 400 | 3501 | 1.3 - 1.51 | 22 | 1590 | 2280 | 1900 | 2100 |

| TB 500/12 | 1200 | 1050 | BU 1210 | 1200 | 3160 | - | 400 | 3501 | 1.3 - 1.51 | 23 | 1690 | 2380 | 1850 | 2300 |

| TB 600/12 | 1200 | 1050 | BU 1310 | 1300 | 3430 | - | 500 | 4201 | 1.3 - 1.51 | 25 | 1690 | 2380 | 2000 | 2400 |

| TB 650/12 | 1200 | 1050 | BP 1000 | 1400 | 3690 | - | 500 | 4201 | 1.3 - 1.51 | 26 | 1760 | 2450 | 1630 | 2300 |

| TB 700/12 | 1200 | 1050 | BU 1510 | 1500 | 3960 | - | 500 | 4201 | 1.3 - 1.51 | 28 | 1690 | 2380 | 2120 | 2600 |

| TB 800/12 | 1200 | 1050 | BU 1800 | 1800 | 4750 | - | 500 | 4401 | 1.3 - 1.51 | 30 | 1760 | 2450 | 2100 | 2800 |

| Cu | Cu | Without lid | ||||||||||||

| TB 10/14 | 1400 | 1250 | A 100 | - | - | 100 | 210 | 902 | 1.0 - 1.32 | 16 | 980 | 1590 | 1190 | 1000 |

| TB 20/14 | 1400 | 1250 | A 150 | - | - | 150 | 210 | 1002 | 1.0 - 1.32 | 17 | 1080 | 1870 | 1310 | 1250 |

| TB 40/14 | 1400 | 1250 | A 400 | - | - | 400 | 300 | 3002 | 1.0 - 1.32 | 23 | 1210 | 2000 | 1460 | 1500 |

| TB 60/14 | 1400 | 1250 | A 500 | - | - | 500 | 320 | 3202 | 1.0 - 1.32 | 26 | 1210 | 2000 | 1510 | 1600 |

| TB 80/14 | 1400 | 1250 | A 600 | - | - | 600 | 320 | 3202 | 1.0 - 1.32 | 29 | 1260 | 2050 | 1540 | 1750 |

| 1Al at 700 °C 2CuZn at 1000 °C 3The stated melting performances are maximum values. Daily operation comes up to roughly 80 %. 4External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 5 Values for other materials, e. g. zinc, on request |

||||||||||||||