機能と設備

LH 120/13 DB

冷却時間を加速するための空気流入ファン付きチャンバー炉LH 216/12

Chamber furnace LH 60/13 DB50 for debinding in air

チャンバー炉LH30/12、手動リフトドア

冷却時間を加速するための新鮮な空気ファンのあるチャンバー炉 LF 60/14

チャンバー炉LH 30/14

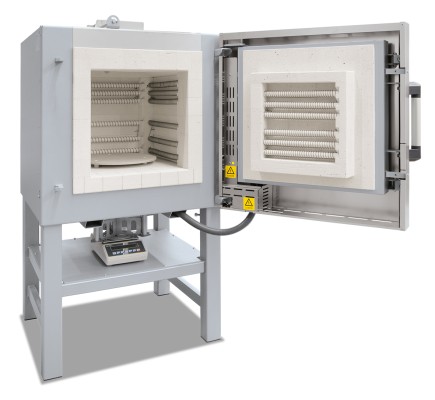

チャンバー炉LH 60/12 SW 熱灼減量測定のための計量装置付き

平行スイング式扉 高温時の炉の開閉

不燃性保護ガスまたは反応ガス (N2、Ar、He、CO2、空気、フォーミングガス)用のガスパネル

Model with brick base

短時間の加熱と冷却のためのLFモデルタイプ

In the standard version, the LH .. and LF .. models are designed for sintering processes in air. For debinding and sintering processes on a laboratory scale, these furnaces can be equipped with the DB50 laboratory version designed for low evaporation rates. By introducing fresh air, the furnace is operated with overpressure during the debinding phase.

- Tmax 1200 °C, 1300 °C, or 1400 °C

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- High furnace chamber with five-sided heating for very good temperature uniformity

- Heating elements on support tubes ensure free heat radiation and a long service life

- Controller mounted on furnace door and removable for comfortable operation

- Protection of bottom heating and flat stacking surface provided by embedded SiC plate in the floor

- LH models: multi-layered insulation of light refractory bricks and special backup insulation

- LF models: high-quality fiber insulation with corner bricks for shorter heating and cooling times

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Motorized exhaust air flap

- Freely adjustable air inlet integrated in furnace floor

- Base included

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500 (5 programs with each 4 segments)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via Excel™ for Windows™ on the PC

- Freeware NTGraph for evaluation and documentation of firings using Excel™ for Windows™ on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Debinding Package DB50

- Laboratory version for applications with low evaporation rates for chamber furnaces LH 30/.. to LH 120/..

- Fresh air fan for introducing a defined amount of fresh air

- Exhaust gas and exhaust air discharged via one outlet with a motor-driven flap in an exhaust hood

付加装置

- Parallel swinging door (user protected from heat radiation)

- Lift door with electro-mechanic linear drive for opening when hot

- Cooling system to cool the furnace with a defined temperature gradient or with a preset fresh air volume. Both operating modes can be switched on and off for different segments by means of the extra function of the controller.

- Protective gas connection to purge with non-flammable process gases

- Manual or automatic gas supply system

- Stainless steel exhaust hood as interface to customer’s exhaust system

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Process control and documentation via VCD software package for monitoring, documentation and control

技術仕様

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | w | d | h | in l | W | D | H | load in kW | connection* | in kg | |

| LH 15/12 | 1200 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 5 | 3-phase2 | 170 |

| LH 30/12 | 1200 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 7 | 3-phase2 | 200 |

| LH 60/12 | 1200 | 400 | 400 | 400 | 60 | 790 | 1180 | 1370 | 8 | 3-phase | 300 |

| LH 120/12 | 1200 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 12 | 3-phase | 410 |

| LH 216/12 | 1200 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 20 | 3-phase | 470 |

| LH 15/13 | 1300 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 7 | 3-phase2 | 170 |

| LH 30/13 | 1300 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 8 | 3-phase2 | 200 |

| LH 60/13 | 1300 | 400 | 400 | 400 | 60 | 790 | 1180 | 1370 | 11 | 3-phase | 300 |

| LH 120/13 | 1300 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 15 | 3-phase | 410 |

| LH 216/13 | 1300 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 22 | 3-phase | 470 |

| LH 15/14 | 1400 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 8 | 3-phase2 | 170 |

| LH 30/14 | 1400 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 10 | 3-phase2 | 200 |

| LH 60/14 | 1400 | 400 | 400 | 400 | 60 | 790 | 1180 | 1370 | 12 | 3-phase | 300 |

| LH 120/14 | 1400 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 18 | 3-phase | 410 |

| LH 216/14 | 1400 | 600 | 600 | 600 | 216 | 990 | 1280 | 1590 | 26 | 3-phase | 470 |

| LF 15/13 | 1300 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 7 | 3-phase2 | 150 |

| LF 30/13 | 1300 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 8 | 3-phase2 | 180 |

| LF 60/13 | 1300 | 400 | 400 | 400 | 60 | 790 | 1180 | 1370 | 11 | 3-phase | 270 |

| LF 120/13 | 1300 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 15 | 3-phase | 370 |

| LF 15/14 | 1400 | 250 | 250 | 250 | 15 | 680 | 860 | 1230 | 8 | 3-phase2 | 150 |

| LF 30/14 | 1400 | 320 | 320 | 320 | 30 | 710 | 930 | 1290 | 10 | 3-phase2 | 180 |

| LF 60/14 | 1400 | 400 | 400 | 400 | 60 | 790 | 1180 | 1370 | 12 | 3-phase | 270 |

| LF 120/14 | 1400 | 500 | 500 | 500 | 120 | 890 | 1180 | 1470 | 18 | 3-phase | 370 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Heating only between two phases | |||||||||||