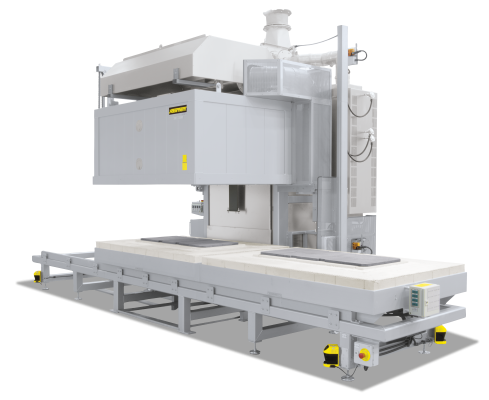

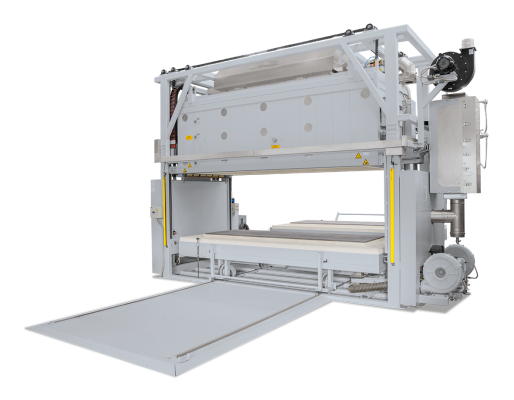

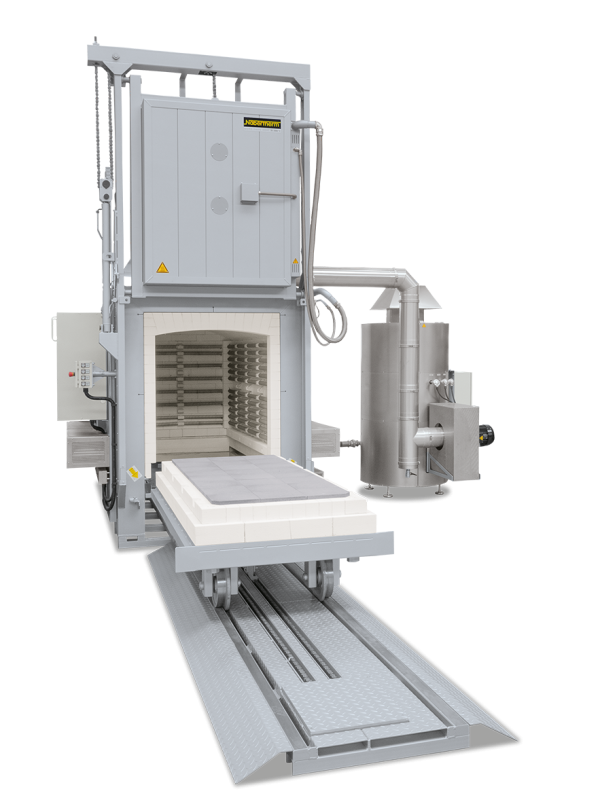

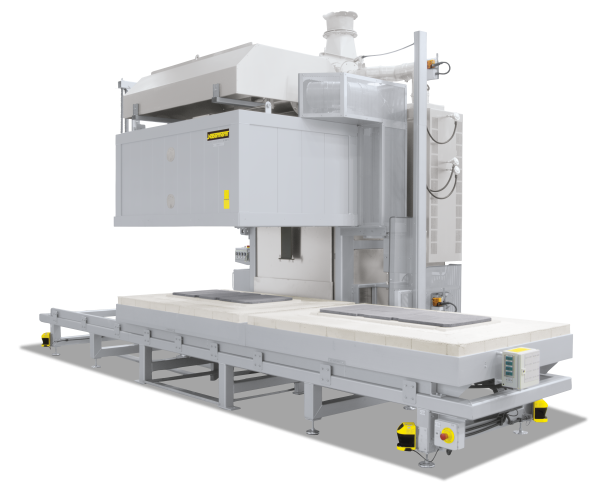

Combi-Top Hat Furnaces or Combi-Bottom Loading Furnaces with Wire Heating up to 1400 °C for Debinding and Sintering in One Process

For small amounts of binder, the basic versions of the combi top hat and bottom loading furnaces are equipped with the DB100 debinding package.

Функции и оборудование

Like the bogie hearth furnace, the top hat and bottom loading furnaces will be equipped with a safety system for debinding in air to allow for a safe operation of debinding and sintering processes performed in one step. Based on the dilution principle, fresh air will be supplied to the furnace chamber in a controlled way to reliably prevent a combustible atmosphere forming inside the furnace by the exhaust gases evaporating from the charge. In addition, debinding-related functions will be monitored to protect the operator and the surrounding.

For small amounts of binder, the basic versions of the combi top hat and bottom loading furnaces are equipped with the DB100 debinding package. With this package, pre-heated fresh air is blown into the furnace so that the combi bogie hearth furnace is operated with overpressure during the debinding phase.

The DB200 debinding package is used for alternating debinding processes and/or large amounts of binder. Like the DB100 debinding package, preheated fresh air is supplied to the furnace chamber via a fresh air fan with air preheater. The furnace also has an exhaust gas fan, which removes the exhaust gases from the furnace via a separate outlet during debinding. For this purpose, the flow rates of the fresh air and exhaust gas are coordinated to ensure that there is always a slight underpressure in the furnace chamber during debinding.

- Tmax 1280 °C

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Top hat furnaces (model LT): Electric or hydraulic hood drive with fixed table

Bottom loading furnaces (model LB): driven table and fixed top hat - Five-sided heating from all four sides and from the table provides for a temperature uniformity up to +/− 5 °C according to DIN 17052-1

- Heating elements on support tubes provide for free heat radiation and long service life

- Bottom heating protected by SiC tiles with an even stacking base

- Multi-layer insulation consisting of lightweight refractory bricks backed by special insulation

- Long-life ceiling design with fiber insulation

- Automatic exhaust air flap on the furnace roof

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- HiProSystems H1700, including Siemens PLC control system and 7" touchpanel as operating interface

Debinding Package DB100

- Basic design for safe debinding operation with small amounts of binder

- Fresh air fan and fresh air preheater

- Exhaust gas and exhaust air removed via one outlet with a motor-driven flap in an exhaust hood

- Performance of the debinding package customized to the process requirements

Debinding Package DB200

- Professional solution for large amounts of binder and changing debinding processes

- Fresh air fan, fresh air preheater and monitoring of fresh air and exhaust gas flow rates

- Separate discharge of exhaust gases during debinding and exhaust air during cooling via separate outlets with motor-driven flaps

- Extendable with catalytic or thermal post combustion for a single furnace or alternating operation with two furnaces

- Performance of the debinding package customized to the process requirements

Дополнительное оборудование

- Tmax 1400 °C

- Sides with fiber insulation to reduce cycle times

- Fabric cover on the fiber roof (and sides) to reduce fiber dust

- Multiple-zone control, adapted for the respective furnace model to optimize temperature uniformity

- Additional tables, interchangeable table system, also motorized

- With debinding package DB200: Thermal or catalytic exhaust air treatment systems

- Redundant thermocouples to increase process reliability

- Calibration interfaces for the measuring section

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента — от малых лабораторных печей до комбинированной печной установки для депарафинизации и спекания в одном процессе — вы найдете в нашем каталоге «Продвинутые материалы».