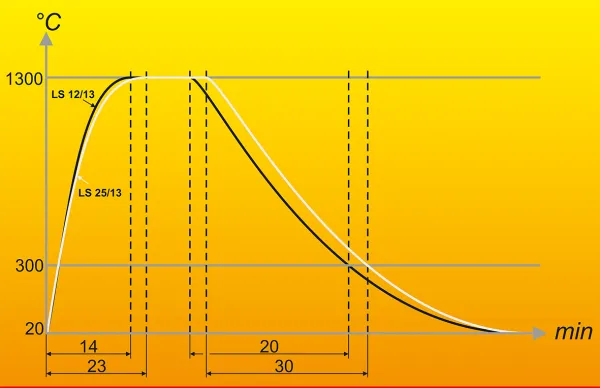

These fast-firing furnaces are ideal for simulation of typical fast-firing processes up to a maximum firing temperature of 1300 °C. The combination of high performance, low thermal mass and powerful cooling fans provides for cycle times from cold to cold up to 35 minutes with an opening temperature of approx. 300 °C.

Standard Equipment

- Tmax 1300 °C

- Ceramic grid tubes as charge support

- Floor and lid heating, two-zone control

- Special arrangement of the heating elements for optimum temperature uniformity

- Rapid switching cycles result in precise temperature control

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Integrated cooling fans, programmable to speed up charge cooling including housing cooling

- Programmable lid opening of approximately 60 mm for faster cooling without activating the fan

- Thermocouple type S for top and bottom zone

- Castors for easy furnace moving

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P570 (50 programs with each 40 segments)