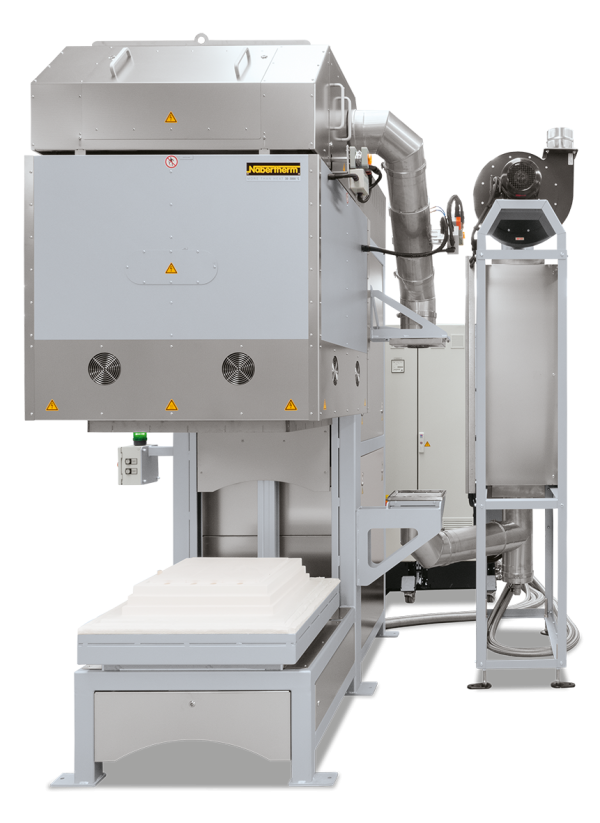

Комбинированные высокотемпературные печи для удаления вяжущих присадок и спекания за один процесс

Менее крупные модели печей могут быть оснащены лабораторным устройством для удаления вяжущих присадок DB50, которое рассчитано на небольшое количество вяжущих веществ и низкие скорости испарения. В базовом исполнении для больших печей доступно устройство для удаления вяжущих присадок DB100.

Функции и оборудование

For combined debinding and sintering processes with sintering temperatures up to 1750 °C, the high-temperature furnaces will be equipped with a passive safety system which ensures a safe operation by monitoring all functions relevant during debinding . In addition, fresh air is supplied to the furnace chamber in a controlled way to reliably prevent a combustible atmosphere forming inside the furnace by diluting the binder gases.

The smaller furnace models can be equipped with the DB50 laboratory debinding package, which is designed for small binder amounts and low vaporization rates. In the basic design, the DB100 debinding package is available for larger furnaces. With this debinding package, preheated fresh air is introduced so that the furnace is operated with overpressure during the debinding phase.

The DB200 debinding package is the ideal solution for high-temperature furnaces used in production processes. With this safety system, the furnace has a fresh air preheater and the preheated air is blown into the furnace horizontally through perforated air inlet tubes. During debinding, the exhaust gases are discharged from the furnace via a separate outlet with exhaust gas fan. The volume flows of fresh air and exhaust gas are controlled so that a slight negative pressure is always maintained in the furnace chamber during debinding.

- Like high-temperature furnaces HT, however:

- Stainless steel exhaust hood as interface to the customer's extraction system (DB200 option: separate removal of exhaust gases during debinding)

- Controller with touch operation P570 (50 programs each with 40 segments) for models HT 16.. - HT 40..

- From model HT 64..: HiProSystems H1700, including Siemens PLC control system and 7" touchpanel as operating interface

Debinding Package DB50

- Laboratory option for applications with low evaporation rates for high-temperature furnaces HT 16.. - HT 40..

- Fresh air fan to introduce a defined volume of fresh air

- Exhaust gas and exhaust air discharged via one outlet with a motor-driven flap in an exhaust hood

Debinding Package DB100

- Basic design for safe debinding with small amounts of binder for high-temperature furnaces from model HT 64..

- Fresh air fan and fresh air preheater

- Exhaust gas and exhaust air discharged via one outlet with a motor-driven flap in an exhaust hood

- Performance of the debinding package customized to the process requirements

Debinding Package DB200

- Professional solution for large amounts of binder and changing debinding processes

- Fresh air fan, fresh air preheater and monitoring of fresh air and exhaust gas flow rates

- Separate discharge of exhaust gases during debinding and exhaust air during cooling via separate outlets with motor-driven flaps

- Extendable with catalytic or thermal post combustion for a single furnace or alternating operation with two furnaces

- Performance of the debinding package customized to the process requirements

Дополнительное оборудование

- With debinding package DB200: Thermal and catalytic exhaust air treatment

- Redundant thermocouples to increase process reliability

- Thermocouple to control the heating with calibration certificate

- Calibration interfaces for the measuring section

- Thermocouple exchange system for temperature measurement via thermocouple types B and S with automatic removal device for more exact control during debinding (for models from HT 160/..)

- Special heating elements e.g. for zirconia applications

Спецификации

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating power | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

°C | w | d | h | in l | W | D | H | in kW3 | connection | in kg | |

HT 16/.. DB50 | 200 | 300 | 260 | 16 | 810 | 645 | 1780 | 12.0 | 3-phase2 | 280 | |

HT 29/.. DB50 | 275 | 300 | 300 | 29 | 975 | 690 | 1910 | 9.3 | 3-phase2 | 390 | |

HT 40/.. DB50 | 1600 | 300 | 350 | 350 | 40 | 1000 | 750 | 1910 | 12.0 | 3-phase | 430 |

HT 64/.. DB100-1 | or | 400 | 400 | 400 | 64 | 1190 | 870 | 1960 | 18.0 | 3-phase | 660 |

HT 64/.. DB200-.. | 1750 | 400 | 400 | 400 | 64 | 1190 | 870 | 1960 | 18.0 | 3-phase | 820 |

HT 160/.. DB100-.. | or | 500 | 550 | 550 | 160 | 1240 | 995 | 2230 | 21.0 | 3-phase | 815 |

HT 160/.. DB200-.. | 1800 | 500 | 550 | 550 | 160 | 1240 | 995 | 2230 | 21.0 | 3-phase | 880 |

HT 276/.. DB200-.. | 500 | 1000 | 550 | 276 | 1300 | 1500 | 2230 | 36.0 | 3-phase | 1300 | |

HT 450/.. DB200-.. | 500 | 1150 | 780 | 450 | 1350 | 1690 | 2500 | 64.0 | 3-phase | 1450 | |

1Outer dimensions vary depending on the scope of supply. Dimensions on request. | |||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента — от малых лабораторных печей до комбинированной печной установки для депарафинизации и спекания в одном процессе — вы найдете в нашем каталоге «Продвинутые материалы».