Трубчатые печи

Nabertherm предлагает широкий ассортимент стандартных трубчатых печей для использования в лабораториях или экспериментальных цехах.

Функции и оборудование

Tube furnaces can be used for many different processes. The extensive range of additional equipment enables precise configuration to suit the respective requirements. Tube furnaces have an unbeatable price/performance ratio, especially for processes in a protective gas atmosphere or in vacuum.

Nabertherm has a wide range of standard tube furnaces for use in laboratories or pilot plants. For detailed descriptions, refer to our catalog “Laboratory Furnaces“.

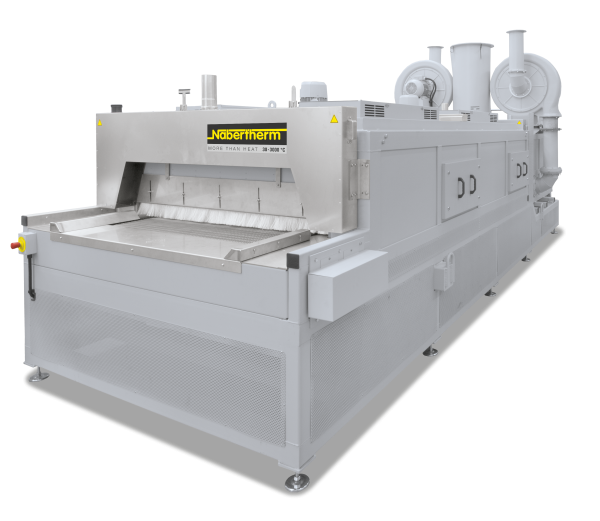

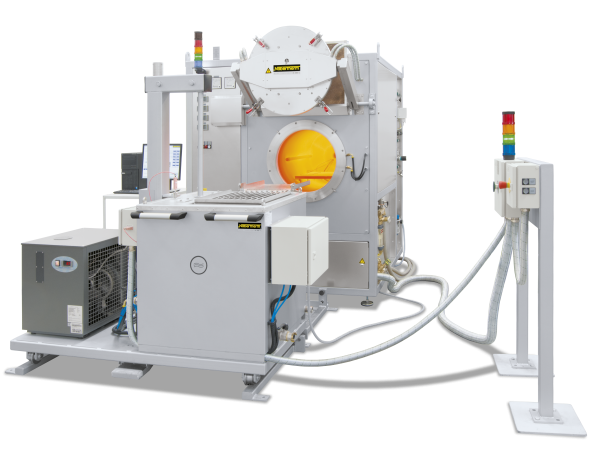

Special Tube Furnaces for the Production of Glass Fiber Material for Heat Treatment of Glass Powder/Granules and Preforms

Custom-built furnaces, such as for cleaning glass powder/granules, for sintering or for degassing preforms.

The furnaces are designed according to our customers’ specifications. The customer integrates them into its production system. Furnace model, temperature, size, and interfaces to higher-level systems are agreed individually for each project.

Дополнительное оборудование

Examples of Possible Additional Equipment

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Working tubes made from various materials, such as ceramic, quartz glass, or metal

- Gas supply system packages for protective gas and vacuum operation

- Vacuum components, such as pumps, connection kits, and sensors

- Safety package for processes in a hydrogen atmosphere

- Process control and documentation with VCD software package or Nabertherm Control Center NCC for monitoring, documentation, and control

Спецификации

Furnace group | Model | Tube diameter in mm | Heated length in mm | Tmax in °C | |||

|---|---|---|---|---|---|---|---|

from | to | from | to | from | to | ||

Compact tube furnaces | R, RD | 30 | 170 | 200 | 1000 | 1200 | 1300 |

Tube furnaces with stand for horizontal and vertical operation | RT | 30 | 50 | 200 | 250 | 1100 | 1500 |

High-temperature tube furnaces with SiC rod heating | RHTC | 80 | 80 | 230 | 710 | 1500 | 1500 |

High-temperature tube furnaces with MoSi2-heating for horizontal or vertical operation | RHTH, RHTV | 50 | 120 | 150 | 600 | 1600 | 1800 |

Split-type tube furnaces for horizontal or vertical operation | RS | 50 | 170 | 250 | 1000 | 1100 | 1300 |

Rotary tube furnaces for batch operation | RSRB | 80 | 120 | 500 | 1000 | 1100 | 1100 |

Rotary tube furnaces for processes with continuous movement | RSRC | 80 | 120 | 500 | 1000 | 1100 | 1300 |

Запрос коммерческого предложения

Другие продукты

каталог

В нашем каталоге «Волоконная оптика/стекло» представлен полный обзор нашего обширного ассортимента печей с выдвижным подом, колпаковых печей, печей для расплавления стекла и остальных моделей для обработки стекла.