Manufacturing Fiber Optics

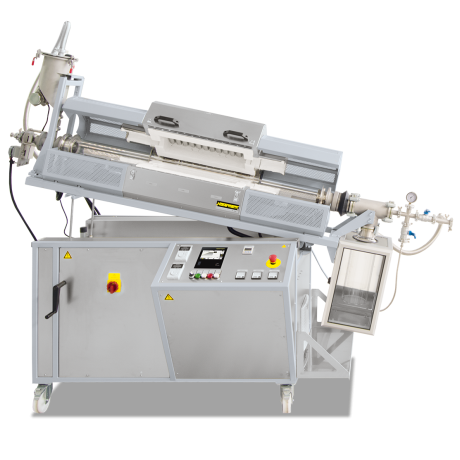

From a technical aspect, manufacturing fiber optics is a very challenging process that requires numerous heat treatment steps. Even the raw material – glass powder or granules – is generally heated in a special atmosphere to clean it. Other processes include sintering and degassing preforms. Due to the linear geometry, the flexible design for different atmospheres and the possibility to control local temperature gradients very accurately, in many cases customized tube furnaces are used in the production of fiber optics. With regard to temperature, size and interfaces to higher-level systems or sub-systems, the specifications of the furnace systems are customized to suit the customer’s individual requirements.