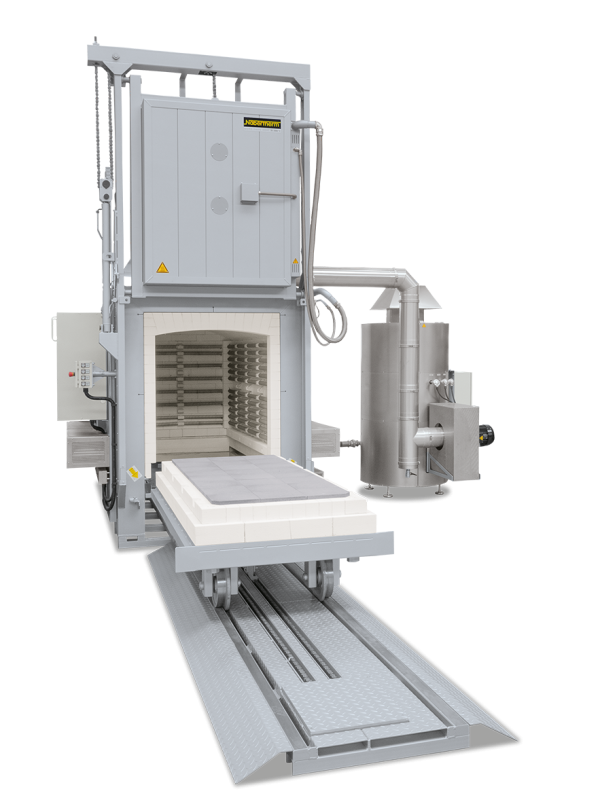

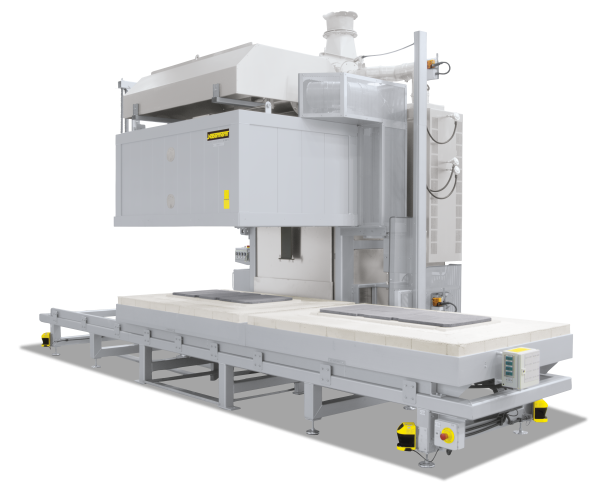

Combi Chamber Furnaces up to 1400 °C for debinding and sintering in one process

The furnaces have a fresh air supply providing for dilution of the exhaust gases produced during debinding, for safe prevention of an inflammable atmosphere in the furnace chamber.

Function and equipment

The combi chamber furnaces N 100 DB - N 1500/14 DB are specially developed for debinding and sintering in one process. The furnaces have a fresh air supply providing for dilution of the exhaust gases produced during debinding, for safe prevention of an inflammable atmosphere in the furnace chamber. The standard version of the furnaces is equipped with the debinding package DB100. This debinding package provides for an injection of fresh air for atmosphere dilution which means that the furnace works under overpressure during debinding.

As a professional solution for production furnaces, we recommend the debinding package DB200. The furnace then has a warm fresh-air injection with variable speed through distribution tubes in the furnace chamber. The exhaust fan operates also with a variable fan speed. The PLC automatically regulates a negative pressure inside the furnace chamber.

- Tmax 1280 °C, 1340 °C or 1400 °C

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Five-sided heating from all four sides and from the floor for a good temperature uniformity

- Heating elements on support tubes provide for free heat radiation and long service life

- Multi-layer insulation consisting of lightweight refractory bricks backed by special insulation

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Self-supporting and long-life ceiling construction, with bricks laid in arched construction

- Bottom heating protected by SiC tiles with an even stacking base

- Motorized exhaust air flap on the furnace roof

- Debinding package DB50 for chamber furnace N 100..

- From model N 200: debinding package DB100 with fresh-air fan, air-preheater and controls

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Defined application within the constraints of the operating instructions

- Controller with touch operation P570 (50 programs with each 40 segments) for models N 100..

- From model N 200: HiProSystems H1700, including Siemens PLC control and 7” touch panel as operator interface

Additional equipment

- Multi-zone control adapted to the particular furnace model for optimizing the temperature uniformity

- Commissioning of the furnace with test firing and temperature uniformity measurement (also with load) for the purpose of process optimization

- Debinding package DB200 with safety concept

- Thermal or catalytic exhaust cleaning systems

- Redundant thermocouples to increase process safety

- Calibration interfaces for the measring range

- SiC support beams for ease of loading/unloading using a forklift

- Guiding rails for forklift

Technical specifications

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating power for single-zone heating control | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | kW2 | connection | in kg | |

| N 100 DB50 | 1280 | 400 | 530 | 460 | 90 | 1100 | 1150 | 1850 | 11 | 3-phase | 350 |

| N 200 DB.. | 1280 | 400 | 530 | 720 | 140 | 850 | 1350 | 2220 | 15 | 3-phase | 500 |

| N 300 DB.. | 1280 | 450 | 700 | 780 | 230 | 900 | 1600 | 2280 | 20 | 3-phase | 800 |

| N 450 DB.. | 1280 | 550 | 760 | 1000 | 350 | 1390 | 1570 | 2520 | 40 | 3-phase | 1400 |

| N 650 DB.. | 1280 | 660 | 850 | 1100 | 610 | 1250 | 1680 | 2720 | 62 | 3-phase | 1600 |

| N 1000 DB.. | 1280 | 740 | 1000 | 1250 | 940 | 1800 | 1800 | 2800 | 57 | 3-phase | 2700 |

| N 1500 DB.. | 1280 | 840 | 1200 | 1400 | 1400 | 1660 | 2300 | 2950 | 75 | 3-phase | 3300 |

| N 100/H DB50 | 1340 | 400 | 530 | 460 | 90 | 1100 | 1150 | 1850 | 15 | 3-phase | 350 |

| N 200/H DB.. | 1340 | 400 | 530 | 720 | 140 | 850 | 1350 | 2220 | 22 | 3-phase | 500 |

| N 300/H DB.. | 1340 | 450 | 700 | 780 | 230 | 900 | 1600 | 2280 | 30 | 3-phase | 800 |

| N 450/H DB.. | 1340 | 550 | 760 | 1000 | 350 | 1390 | 1570 | 2520 | 40 | 3-phase | 1400 |

| N 650/H DB.. | 1340 | 660 | 850 | 1100 | 610 | 1250 | 1680 | 2720 | 62 | 3-phase | 1600 |

| N 1000/H DB.. | 1340 | 740 | 1000 | 1250 | 940 | 1800 | 1800 | 2800 | 75 | 3-phase | 2700 |

| N 1500/H DB.. | 1340 | 840 | 1200 | 1400 | 1400 | 1660 | 2300 | 2950 | 110 | 3-phase | 3300 |

| N 100/14 DB50 | 1400 | 400 | 530 | 460 | 90 | 1100 | 1150 | 1850 | 15 | 3-phase | 350 |

| N 200/14 DB.. | 1400 | 400 | 530 | 720 | 140 | 850 | 1350 | 2220 | 22 | 3-phase | 500 |

| N 300/14 DB.. | 1400 | 450 | 700 | 780 | 230 | 900 | 1600 | 2280 | 30 | 3-phase | 800 |

| N 450/14 DB.. | 1400 | 550 | 760 | 1000 | 350 | 1390 | 1570 | 2520 | 40 | 3-phase | 1400 |

| N 650/14 DB.. | 1400 | 660 | 850 | 1100 | 610 | 1250 | 1680 | 2720 | 62 | 3-phase | 1600 |

| N 1000/14 DB.. | 1400 | 740 | 1000 | 1250 | 940 | 1800 | 1800 | 2800 | 75 | 3-phase | 2700 |

| N 1500/14 DB.. | 1400 | 840 | 1200 | 1400 | 1400 | 1660 | 2300 | 2950 | 110 | 3-phase | 3300 |

| 1Outer dimensions vary depending on the scope of supply. Dimensions on request. 2Depending on furnace design connected load might be higher | |||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range from the small laboratory furnace up to a combi furnace system for debinding and sintering in one process can be found in our catalog “Advanced Materials”.