Chamber Furnaces with Drawer Bottom or as a Bogie

Free access in front of the furnace allows for a simplified and clear charging.

Function and equipment

The chamber furnaces of NW model series combines the attractive quality advantages of the proven models N 150 - N 1000/H with an outstanding product characteristic which substantially simplifies charging.

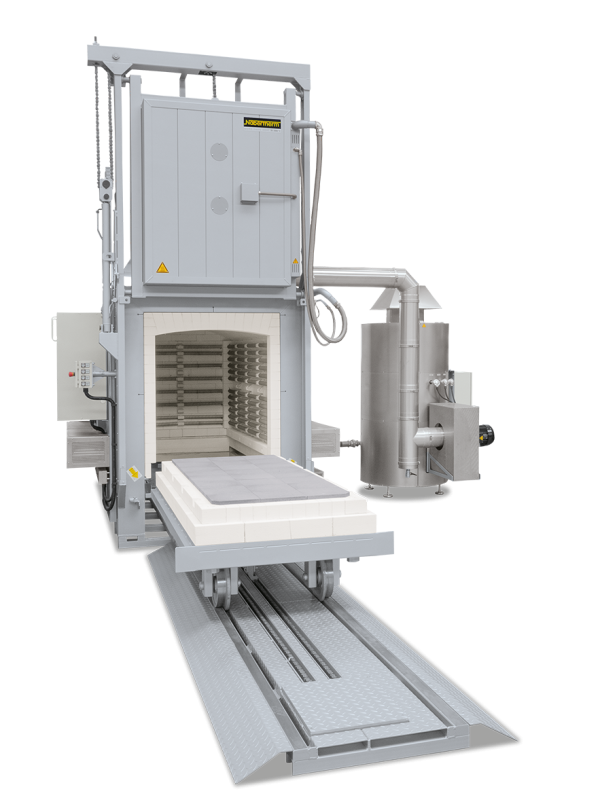

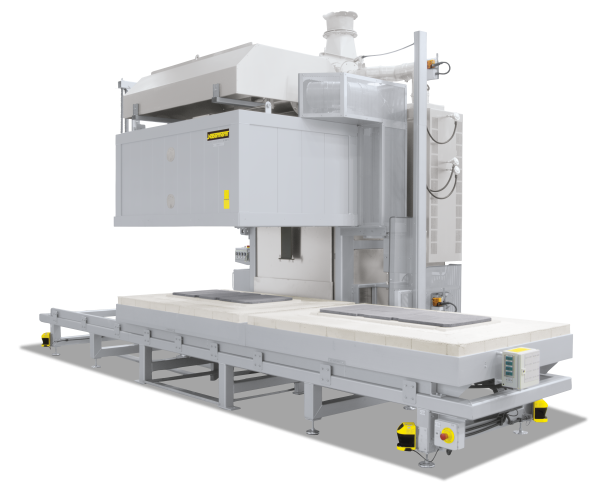

With a drawer mechanism (NW 150 - NW 300/H) the kiln table can be easily pulled out of the chamber kiln. The larger models NW 440 - NW 1000/H are designed as shuttle furnace with completely free traversing bogie. Free access in front of the furnace allows for a simplified and clear charging.

- Tmax 1300 °C or 1340 °C

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

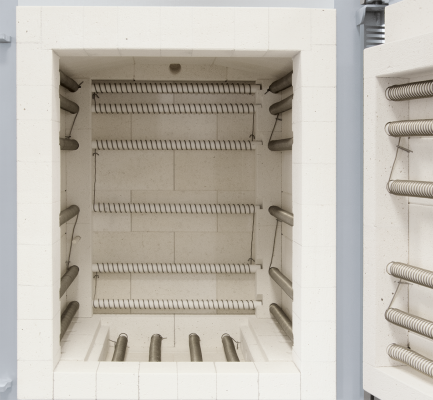

- Five-side heating provide for good temperature uniformity

- Heating elements of support tubes provide for free radiation of the heat

- Multi-layer insulation with light-weight refractory bricks and high-quality, energy-saving backing insulation

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Self-supporting and long-life ceiling construction, with bricks laid in arched construction

- Bottom heating protected by SiC tiles with an even stacking base

- Furnace table can be pulled-out as drawer (NW 150 - NW 300/H)

- From chamber kiln NW 440 bogie on four castors (two with brakes) which can be pulled out completely. Accession assistance and removable drawbar for bogie

- Semi-automatic air inlet flap for chamber kilns up to 300 liters

- Infinitely adjustable, manual air inlet from 440 liters

- Exhaust air opening in the lid, including connection for an exhaust air tube (80 mm diameter) up to 300 liters

- Motorized exhaust air flap in the top of the furnace for optimum ventilation of the furnace chamber and for rapid cooling at low temperatures from 300 liters

- Frame included for furnaces up to 660 liters

- Controller mounted on furnace door and removable for comfortable operation

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500 (5 programs with each 4 segments)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via Excel™ for Windows™ on the PC

- Freeware NTGraph for evaluation and documention of firings using Excel™ for Windows™ on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional equipment

- Motorized exhaust air flap for models NW 150 - NW 300/..

- Fan system for faster cooling with manual or automatic control

- Multi-zone control for optimal temperature uniformity in the work space

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

Model | Tmax | Inner dimensions in mm | Volume in | Outer dimensions1 in mm | Heating power | Electrical | Weight in | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

°C | w | d | h | l | W | D | H | kW2 | connection | kg | |

NW 150 | 1300 | 430 | 530 | 620 | 150 | 810 | 1150 | 1600 | 11 | 3-phase | 420 |

NW 200 | 1300 | 500 | 530 | 720 | 200 | 880 | 1150 | 1700 | 15 | 3-phase | 490 |

NW 300 | 1300 | 550 | 700 | 780 | 300 | 930 | 1320 | 1760 | 20 | 3-phase | 590 |

NW 440 | 1300 | 600 | 750 | 1000 | 450 | 1070 | 1410 | 1830 | 30 | 3-phase | 850 |

NW 660 | 1300 | 600 | 1100 | 1000 | 660 | 1070 | 1750 | 1830 | 40 | 3-phase | 1180 |

NW 1000 | 1300 | 800 | 1000 | 1250 | 1000 | 1460 | 1760 | 2230 | 57 | 3-phase | 2100 |

NW 150/H | 1340 | 430 | 530 | 620 | 150 | 810 | 1150 | 1600 | 15 | 3-phase | 520 |

NW 200/H | 1340 | 500 | 530 | 720 | 200 | 880 | 1150 | 1700 | 20 | 3-phase | 590 |

NW 300/H | 1340 | 550 | 700 | 780 | 300 | 930 | 1320 | 1760 | 27 | 3-phase | 670 |

NW 440/H | 1340 | 600 | 750 | 1000 | 450 | 1070 | 1410 | 1830 | 40 | 3-phase | 940 |

NW 660/H | 1340 | 600 | 1100 | 1000 | 660 | 1070 | 1750 | 1830 | 52 | 3-phase | 1310 |

NW 1000/H | 1340 | 800 | 1000 | 1250 | 1000 | 1460 | 1760 | 2230 | 75 | 3-phase | 2700 |

1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request | |||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range from the small laboratory furnace up to a combi furnace system for debinding and sintering in one process can be found in our catalog “Advanced Materials”.