Suszarki komorowe ogrzewane elektrycznie

Wydajny system cyrkulacji powietrza zapewnia równomierność temperatury w przestrzeni użytkowej.

Funkcja i wyposażenie

Suszarka komorowa KTR 6125

Direct gas-firing at a chamber dryer

KTR 4500 with platform cart, inner lightning and observation windows

Chamber oven KTR 22500/S with chamber lightning and drive-in tracks with insulated plugs which provide for an optimal temperature uniformity

Chamber oven KTR 3100/S for curing of composites in vacuum bags incl. pump and necessary connections in the oven chamber

Chamber oven KTR 6125 DTLS for tempering of parts made of silicone. The basket used with the rotation system are also used for the internal transport of the parts.

Motor-driven rotary rack with baskets for moving the charge during heat treatment

Suszarka komorowa KTR 6250 jako piec śluzowy z podwójnymi drzwiami z przodu i z tyłu oraz torami wsuwania dla wózka załadunkowego

Adjustable plate shutters to adapt the air guide to the charge

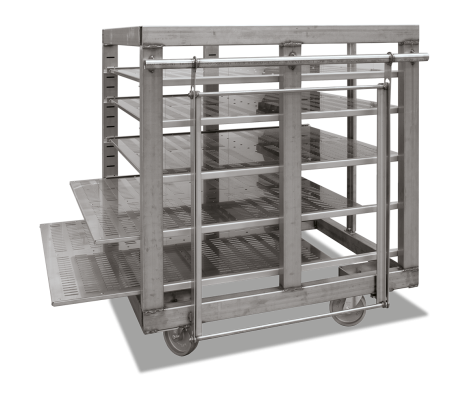

Wózek załadowczy z wyjmowanymi blachami

Wkładane dna wyjmowane na rolkach

The chamber ovens of the KTR range can be used for complex drying processes and heat treatment of charges to an application temperature of 260 °C. The high-performance air circulation enables optimum temperature uniformity throughout the work space. A wide range of accessories allow the chamber ovens to be modified to meet specific process requirements.

- Tmax 260 °C

- Electrically heated (via a heating register with integrated chrome steel heating elements)

- Temperature uniformity up to +/− 3 °C according to DIN 17052-1 (for design without track cutouts)

- High-quality mineral wool insulation provides for outer temperatures of < 25 °C above room temperature

- Incl. floor insulation

- High air exchange for fast drying processes

- Double-wing door for furnaces KTR 2300 and larger

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation B500 (5 programs with 4 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Dodatkowe wyposażenie

- Direct or indirect gas-fired

- Base frame to charge the oven via a charging forklift

- Additional door in the back for charging from both sides or to use the oven as lock between two rooms

- Fan system for faster cooling with manual or motor-driven control of the exhaust flaps

- Programmed opening and closing of exhaust air flaps

- Air circulation with speed control, recommendable for processes with light or sensitive charge

- Observation window and furnace chamber lighting

- Design for clean room heat treatment processes

- Rotating systems e. g. for tempering processes

- All KTR-models are also available with Tmax 300 °C

- Process control and documentation via VCD software package for monitoring, documentation and control

Accessories

- Adjustable plate shutters to adapt the air guide to the charge and improve temperature uniformity

- Guide-in tracks and shelves

- Shelves with 2/3 extraction with evenly distributed load on the whole shelve surface

- Platform cart in combination with drive-in tracks

- Charging cart with rack system in combination with drive-in tracks

- Sealing shoes for ovens with drive-in tracks to improve temperature uniformity in the work space

Specyfikacja techniczna

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating power in kW1 | Electrical | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | connection | ||

| KTR 1000 | 260 | 1000 | 1000 | 1000 | 1000 | 1820 | 1430 | 1890 | 18 | 3-phase |

| KTR 1500 | 260 | 1000 | 1000 | 1500 | 1500 | 1820 | 1430 | 2390 | 18 | 3-phase |

| KTR 2000 | 260 | 1100 | 1500 | 1200 | 2000 | 1920 | 1930 | 2090 | 18 | 3-phase |

| KTR 2300 | 260 | 1250 | 1250 | 1500 | 2300 | 2120 | 1680 | 2460 | 27 | 3-phase |

| KTR 3100 | 260 | 1250 | 1250 | 2000 | 3100 | 2120 | 1680 | 2960 | 27 | 3-phase |

| KTR 3400 | 260 | 1500 | 1500 | 1500 | 3400 | 2370 | 1930 | 2460 | 45 | 3-phase |

| KTR 4500 | 260 | 1500 | 1500 | 2000 | 4500 | 2370 | 1930 | 2960 | 45 | 3-phase |

| KTR 4600 | 260 | 1750 | 1750 | 1500 | 4600 | 2620 | 2175 | 2480 | 45 | 3-phase |

| KTR 6000 | 260 | 2000 | 2000 | 1500 | 6000 | 2870 | 2430 | 2460 | 54 | 3-phase |

| KTR 6125 | 260 | 1750 | 1750 | 2000 | 6125 | 2620 | 2175 | 2980 | 45 | 3-phase |

| KTR 6250 | 260 | 1250 | 2500 | 2000 | 6250 | 2120 | 3035 | 2960 | 54 | 3-phase |

| KTR 8000 | 260 | 2000 | 2000 | 2000 | 8000 | 2870 | 2430 | 2960 | 54 | 3-phase |

| KTR 9000 | 260 | 1500 | 3000 | 2000 | 9000 | 2490 | 3870 | 2920 | 72 | 3-phase |

| KTR 12300 | 260 | 1750 | 3500 | 2000 | 12300 | 2620 | 4350 | 2980 | 90 | 3-phase |

| KTR 13250 | 260 | 1250 | 5000 | 2000 | 13250 | 2120 | 6170 | 2960 | 108 | 3-phase |

| KTR 16000 | 260 | 2000 | 4000 | 2000 | 16000 | 2870 | 4850 | 2960 | 108 | 3-phase |

| KTR 21300 | 260 | 2650 | 3550 | 2300 | 21300 | 3600 | 4195 | 3380 | 108 | 3-phase |

| KTR 22500 | 260 | 2000 | 4500 | 2500 | 22500 | 3140 | 5400 | 3500 | 108 | 3-phase |

| 1Depending on furnace design connected load might be higher 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

||||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców i instalacji do obróbki cieplnej prowadzonej w atmosferze powietrznej można znaleźć w naszym katalogu „Technologia procesów termicznych 1”.