This professional process control with PLC controls for single and multi-zone furnaces is based on Siemens hardware and can be adapted and upgraded extensively. HiProSystems control is used when process-dependent functions, such as exhaust air flaps, cooling fans, automatic movements, etc., have to be handled during a cycle, when furnaces with more than one zone have to be controlled, when special documentation of each batch is required and when remote service is required. It is flexible and is easily tailored to your process or documentation needs.

Alternative User Interfaces for HiProSystems

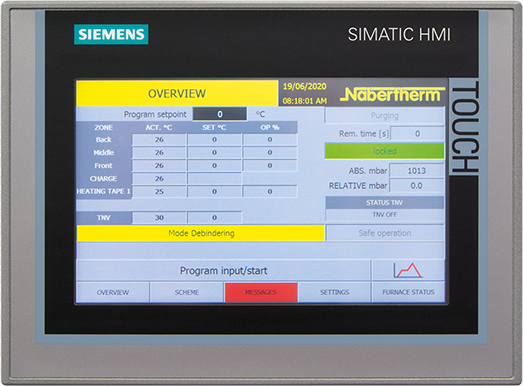

Process control H500

This basic panel accommodates most basic needs and is very easy to use. Firing cycle data and the extra functions activated are clearly displayed in a table. Messages appear as text. Data can be stored on a USB stick using the „NTLog Comfort“ option.

Process control H1700

Customized versions can be realized in addition to the scope of services of the H500. Display of basic data as online trend on a color 7‘‘ display with graphically structured interface.

Process control H3700

Display of functions on a large 12‘‘ display. Display of basic data as online trend or as a graphical system overview. Scope as H1700.

Remote Maintenance Router – Fast Support in Case of a Malfunction

For fast failure diagnosis in case of a malfunction, remote maintenance systems are used for HiProSystems-plants (depending on the model). The plants are equipped with a router, which will be connected to the internet by the customer. In case of a malfunction, Nabertherm is able to get access to the furnace controls via a secured connection (VPN tunnel) and to perform a malfunction diagnosis. In most cases, the problem can be directly solved by e technician on site according with supervision from Nabertherm.

If no Internet connection can be provided, we offer optionally the remote maintenance via LTE network as additional equipment.