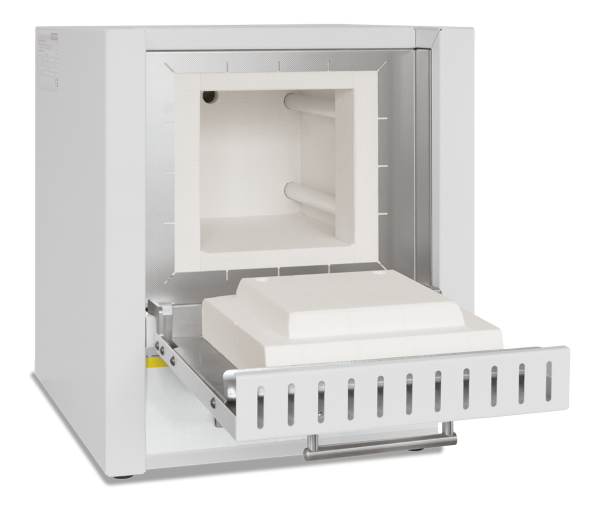

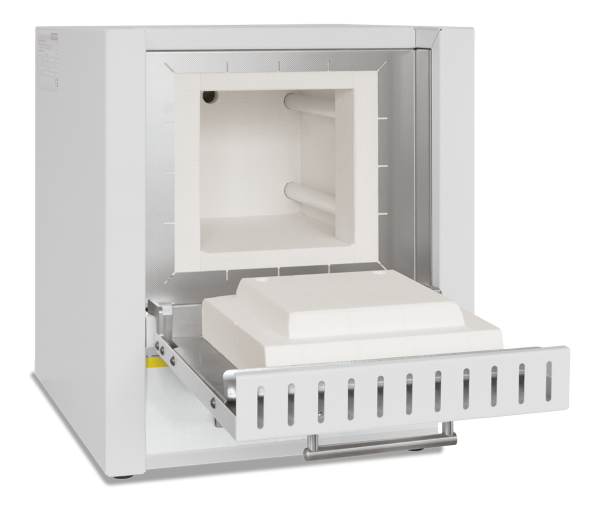

Compact Burnout Furnaces

They convince by very fast possible heating ramps and attractive design.

They convince by very fast possible heating ramps and attractive design.

With their unbeatable price/performance ratio, these compact burnout furnaces are optimally suited for burnout in the dental laboratory. They convince by very fast possible heating ramps and attractive design. Quality features like the dual shell housing, their compact, lightweight design, or the heating elements installed in quartz glass tubes make this burnout furnace a reliable partner for your dental application.

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Temperature uniformity of +/− 5K in the empty workspace4 | Max. connected | Electrical | Weight | Heating time | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C1 | w | d | h | in l | W | D | H | w | d | h | load in kW | connection* | in kg | in min3 | |

| LE 1/11 | 1100 | 90 | 115 | 110 | 1 | 290 | 280 | 410 | 40 | 65 | 60 | 1.6 | 1-phase | 15 | 10 |

| LE 2/11 | 1100 | 110 | 180 | 110 | 2 | 330 | 390 | 410 | 60 | 130 | 60 | 1.9 | 1-phase | 20 | 15 |

| LE 6/11 | 1100 | 170 | 200 | 170 | 6 | 390 | 440 | 470 | 120 | 150 | 120 | 2.0 | 1-phase | 27 | 30 |

| LE 14/11 | 1100 | 220 | 300 | 220 | 14 | 440 | 540 | 520 | 170 | 250 | 170 | 3.2 | 1-phase | 35 | 35 |

| LE 24/11 | 1100 | 260 | 330 | 280 | 24 | 490 | 570 | 590 | 200 | 270 | 230 | 3.5 | 1-phase | 42 | 40 |

| *These furnaces are available for main voltage of 110 V - 120 V resp. 200 V - 240 V, 1/N/PE or 2/PE 1Recommended working temperature for processes with longer dwell times is 1050 °C 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Heating time of the empty and closed furnace up to Tmax −100 K (connected to 230 V 1/N/PE) 4Temperature uniformity of +/− 5 K with closed fresh-air inlet in empty work space according to DIN 17052-1 at working temperatures above 800 °C | |||||||||||||||

A complete overview of our extensive range of sintering and preheating furnaces and accessories for the dental sector can be found in our “Dental” catalog.

We look forward to receiving your inquiry!