PC-based control, process visualization and process documentation software

With the Nabertherm Control Center, a PC-based control system is offered as an ideal extension for furnaces with PLC-based HiProSystem control systems. The system has proven itself in many applications with increased demands on documentation and process reliability and also for convenient multi-furnace management. Many customers from the automotive, aviation, medical technology or technical ceramics sectors are working successfully with this powerful software.

Basic Equipment

- Central operator interface in modern design

- Overview and central operation for up to 8 furnaces

- Convenient program management with 100 programs

- Simple, intuitive operation of the PC user interface

- Access management with 3 user levels and as many users as required

- Charge data input for each furnace operation

- Start times can be specified in order to pre-plan heat treatment cycles

- Tamper-proof, encrypted storage of charge documentation

- Live view of current furnace operations

- Archive with overview of performed cycles

- Search function for charge data and temperature curves of performed cycles

- Report function to assess the process as PDF or printout

- Delivery includes PC, monitor and printer

Aviation/Automotive Design

- Documentation according to AMS2750H (NADCAP) and CQI-9

- Integration of additionally needed thermocouples according to instrumentation type as a switching condition (e.g. start “hold time”)

- Instrumentation type adaptable by customer

- Choice of programmed or continuous operation

- Automatic adjustment of the monitored value for overtemperature protection of the charge

- Calibration for all elements of the measuring section in several temperature ranges

- Calendar function for SAT, IT and TUS measurements

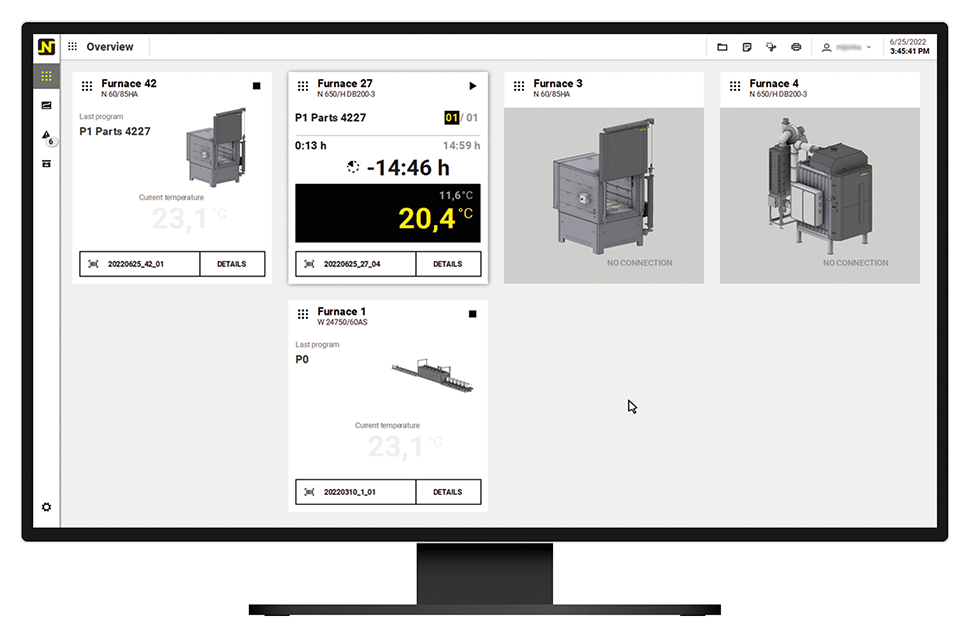

System Overview

With several connected furnaces:

- Overview on actual process values and messages for the connected furnaces

- Symply switching to the furnace overview by selecting a furnace

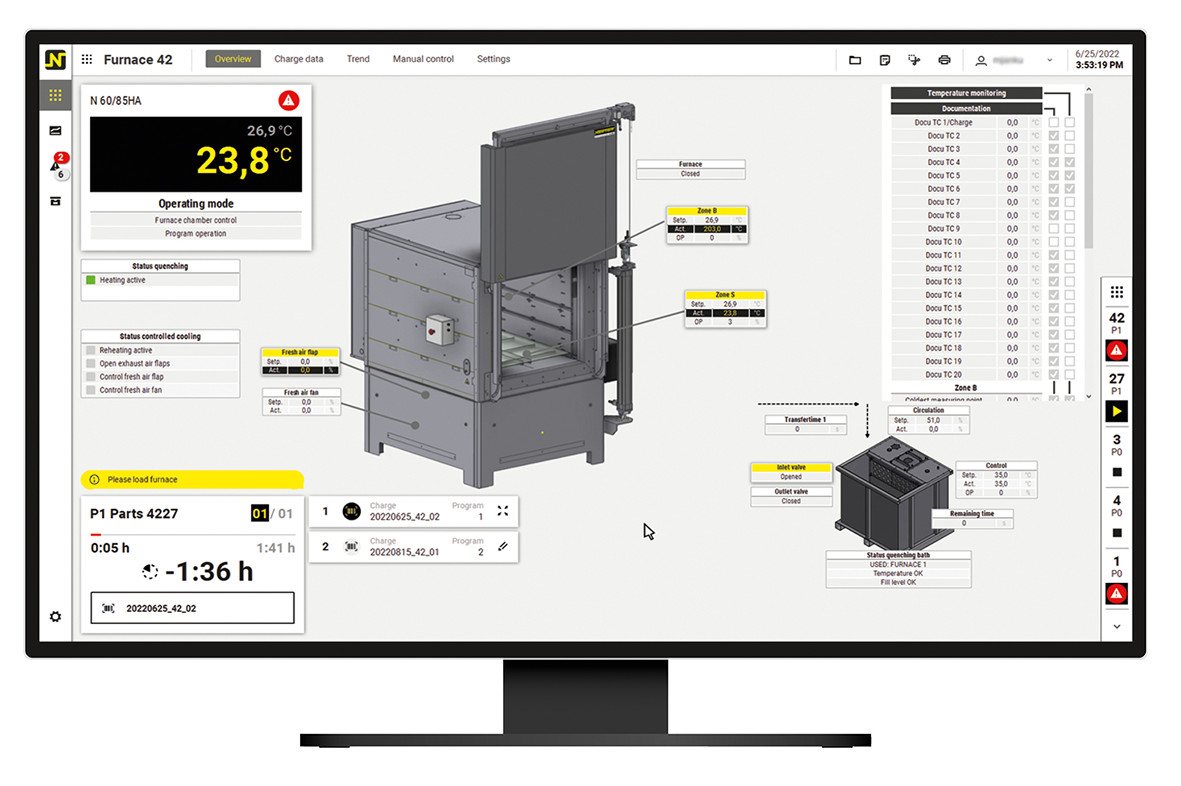

Furnace Overview

- Clear presentation of status information and process values of the furnace/furnace system

- Display of charge information, current value and setpoint, as well as remaining time of the active program

- Direct access to live view, furnace settings and control of furnace functions

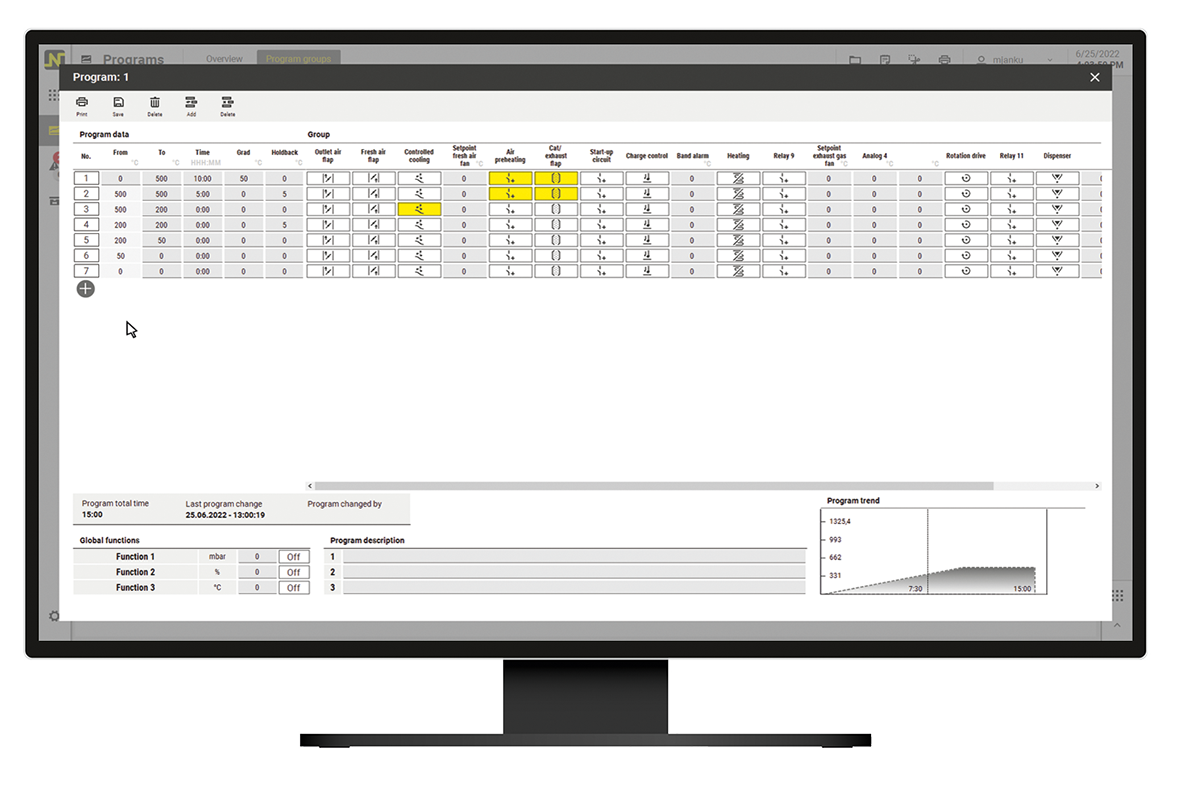

Program Input

- Intuitive program input with plain text fields and clear symbols for the furnace functions

- Free text fields for program name and additional information

- Adjustable number of segments (by default up to 20 segments), function to insert and delete individual segments

- Preview of the setpoint curve for created program

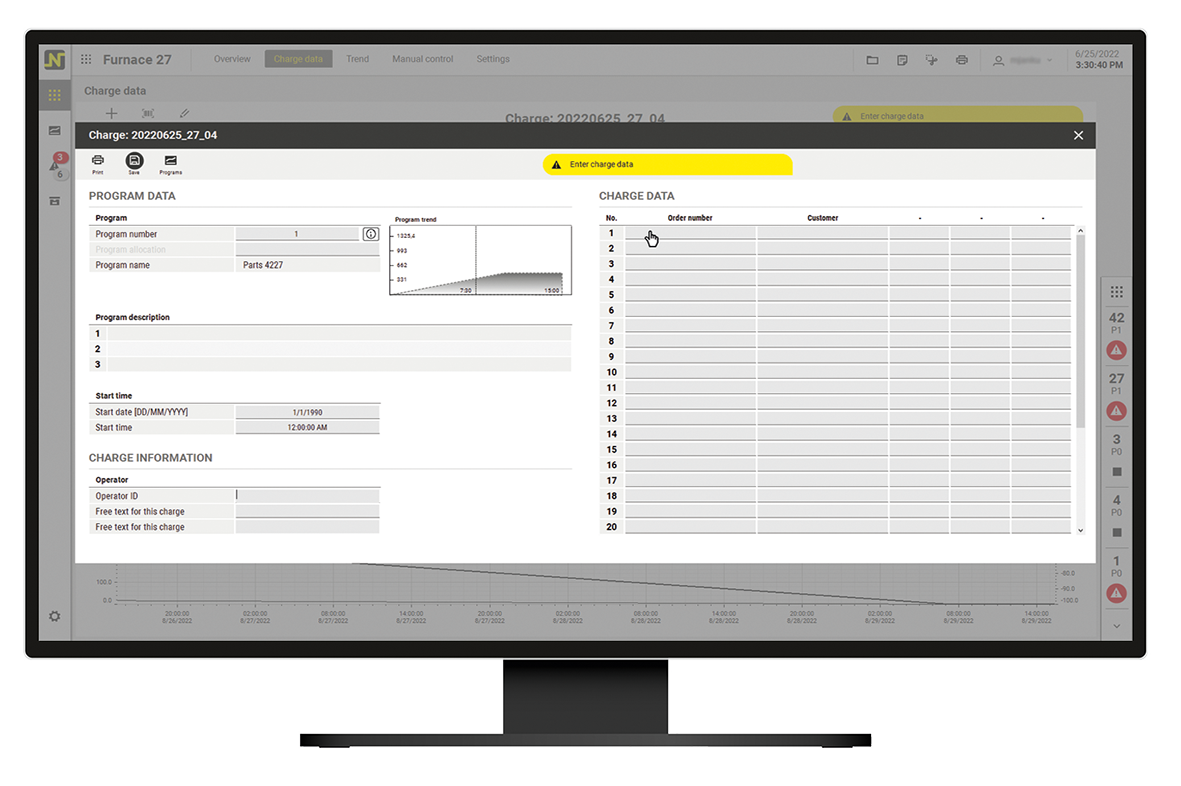

Charge Preparation

- Information texts for guided charge data entry

- Program selection with display of the program name and additional information

- Preview of the setpoint curve for selected program

- Entry of charge data, operator ID and free text fields for additional information

- Start times can be specified in order to pre-plan heat treatment cycles

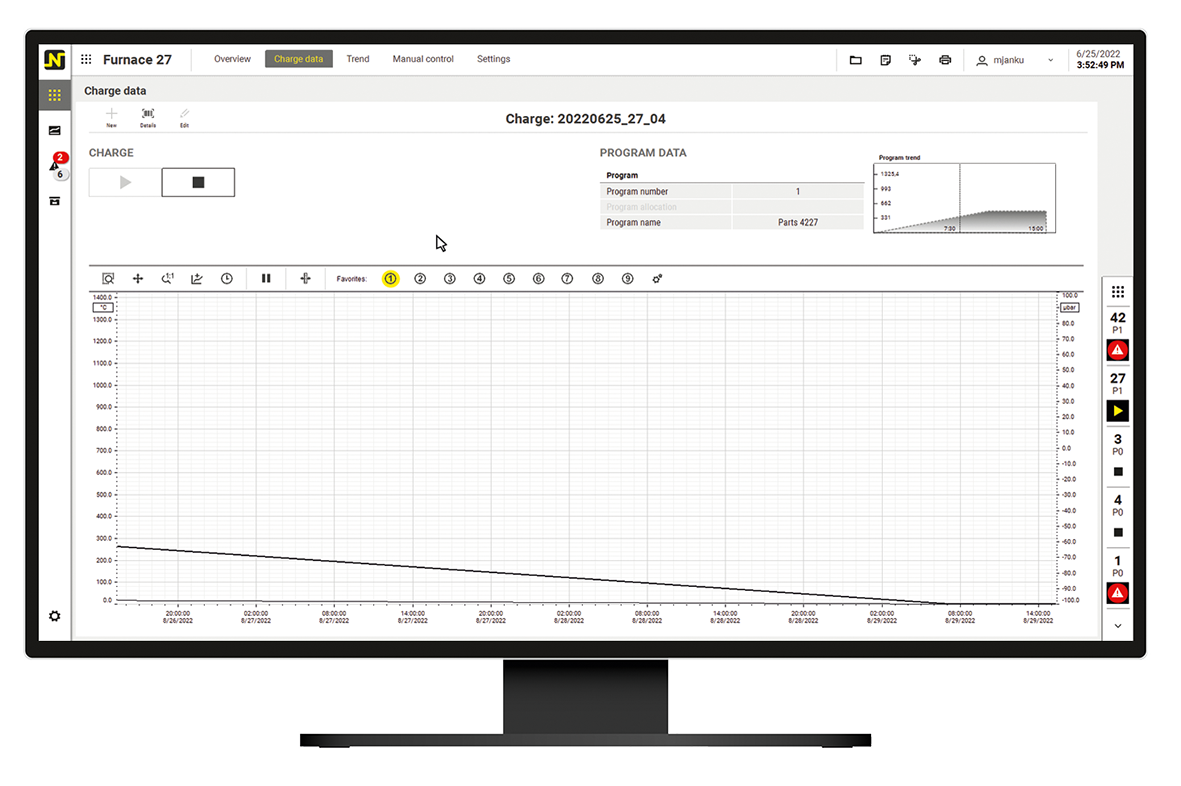

Process Documentation

- Charge and process data is output displayed graphically as a trend, encrypted and saved on the PC in CSV format

- Documentation can be tracked by entering the charge data

- Preview of the setpoint curve for selected program

- Automatic report generation at the end of a process cycle in PDF format with charge data and temperature curve

Extension Options

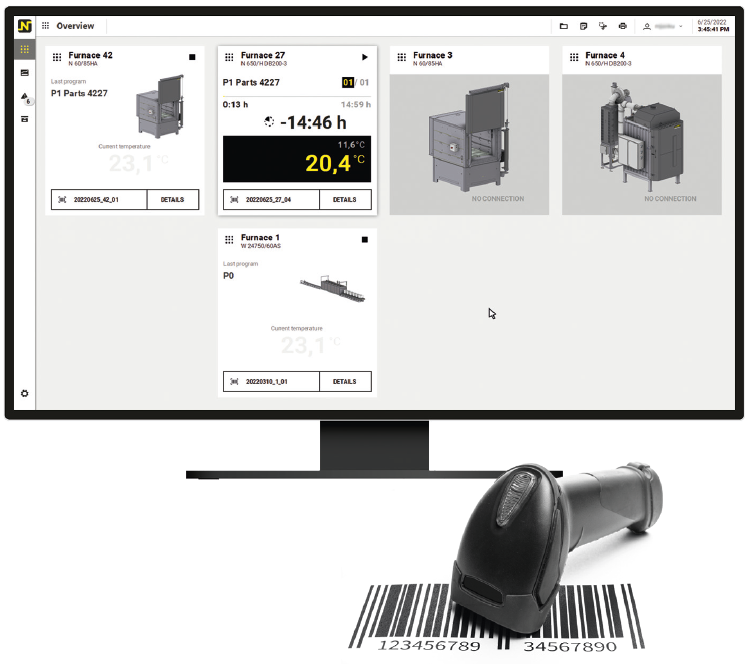

- Enter charge data via barcode

- Simple data recording, ideal for changing charges

- Ensure data quality with defined charge data

- Compare charge and program to increase process reliability

- Access rights via employee cards

- Software extension with documentation according to the requirements of the Food and Drug Administration (FDA), Part 11, EGV 1642/03

- Interface to connect higher level systems (OPC-UA), SQL connection, redundant data storage

- Control from different PC workstations

- Available as panel PC or virtual machine

- PC cabinet with UPS for PC

- Further customization possible on request