機能と設備

熱風循環式チャンバー炉 NA 120/65

熱風循環式チャンバー炉 NA 60/85、前面から積載するための手動リフトドアとガスバージボックス付き

熱風循環式チャンバー炉 NA 250/85

熱電対用のダクト

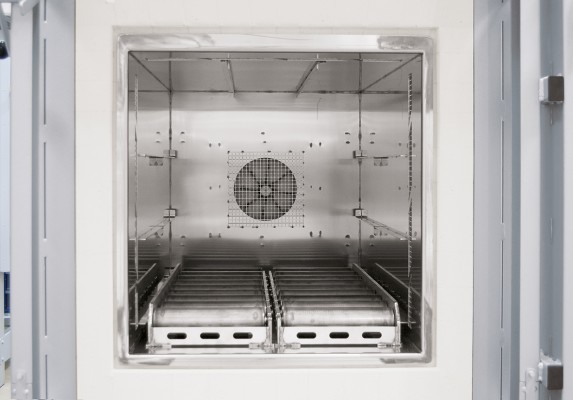

装入トレイ

炉室内のローラーコンベヤ

Due to their very good temperature uniformity, these forced convection chamber furnaces with air circulation are suitable for processes such as stress relieving, artificial aging, and cooling glass as well as pre-heating glass molds. To burn in release agents in glass molds, to burn in organic pastes or to sterilize laboratory glassware, the forced convection chamber furnaces are equipped with the corresponding passive safety concepts. The modular design of the forced convection chamber furnaces allows them to be adapted with appropriate accessories to suit process requirements.

- Tmax 450 °C, 650 °C, or 850 °C

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Horizontal air circulation with optimum distribution through stainless steel baffles

- Swing door hinged on the right

- Base frame included in the delivery

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Temperature uniformity up to +/− 4 °C according to DIN 17052-1 in the empty work space

- One frame sheet and rails for two additional trays included in the scope of delivery

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation B500 (5 programs with each 4 segments)

- Automatic switch-off of air circulating fan for two minutes after door opening

- Side port and additional 3 mm thermocouple entry port

付加装置

Additional Equipment for Models Tmax up to 450 °C

- Air inlet and exhaust air flaps when used for drying

- Controlled cooling with Controller P570, for example, to relieve stresses in glass at low cooling rates (optional: PLC with controlled cooling and optimized control accuracy for cooling rates as low as 0.2 °C per hour)

- Additional frame sheet

- Gas supply boxes for different charging methods

- Gas feed fittings

- Charge control with documentation of the charge thermocouple

- Signal tower

- Feed and charging aids

- Safety technology according to EN 1539 (models NA .. LS) for charges containing solvents

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Further Additional Equipment for Models Tmax up to 650 °C and 850 °C

- Optimization of the temperature uniformity up to +/− 3 °C according to DIN 17052-1 in the empty work space

- Measuring frames and thermocouples for TUS measurements charge or comparative measurements

- Version according to AMS2750H or CQI-9

- Manual lift door for forced convection chamber furnace NA 120/65 and NA 120/85

- Pneumatic lift door from forced convection chamber furnace NA 250/65 upwards

- Manual roller conveyor in furnace chamber for high charge weights

技術仕様

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating | Electrical | Weight | Heat-up time3 | Cool-down time3 from Tmax | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| power | to Tmax | to 150 °C in minutes | ||||||||||||

| °C | w | d | h | in l | W | D | H | in kW2 | connection | in kg | in minutes | Flaps4 | Fan cooling4 | |

| NA 120/45 | 450 | 450 | 600 | 450 | 120 | 1075 | 1475 | 1500 | 9 | 3-phase | 280 | 60 | 90 | 30 |

| NA 250/45 | 450 | 600 | 750 | 600 | 250 | 1250 | 1660 | 1670 | 12 | 3-phase | 650 | 60 | 120 | 30 |

| NA 500/45 | 450 | 750 | 1000 | 750 | 500 | 1400 | 1910 | 1810 | 18 | 3-phase | 800 | 90 | 240 | 45 |

| NA 120/45 LS | 450 | 450 | 600 | 450 | 120 | 1250 | 1550 | 1950 | 18 | 3-phase | 450 | 60 | - | - |

| NA 250/45 LS | 450 | 600 | 750 | 600 | 250 | 1350 | 1650 | 2080 | 24 | 3-phase | 520 | 60 | - | - |

| NA 500/45 LS | 450 | 750 | 1000 | 750 | 500 | 1550 | 1900 | 2220 | 24 | 3-phase | 730 | 90 | - | - |

| NA 60/65 | 650 | 350 | 500 | 350 | 60 | 930 | 1310 | 1435 | 9 | 3-phase | 240 | 90 | 210 | 30 |

| NA 120/65 | 650 | 450 | 600 | 450 | 120 | 1030 | 1410 | 1535 | 12 | 3-phase | 280 | 90 | 240 | 60 |

| NA 250/65 | 650 | 600 | 750 | 600 | 250 | 1250 | 1700 | 1750 | 20 | 3-phase | 650 | 90 | 480 | 60 |

| NA 500/65 | 650 | 750 | 1000 | 750 | 500 | 1400 | 1950 | 1900 | 27 | 3-phase | 850 | 90 | 600 | 90 |

| NA 60/85 | 850 | 350 | 500 | 350 | 60 | 930 | 1310 | 1435 | 9 | 3-phase | 315 | 150 | 480 | 90 |

| NA 120/85 | 850 | 450 | 600 | 450 | 120 | 1030 | 1410 | 1535 | 12 | 3-phase | 390 | 150 | 480 | 120 |

| NA 250/85 | 850 | 600 | 750 | 600 | 250 | 1260 | 1700 | 1810 | 20 | 3-phase | 840 | 180 | 900 | 180 |

| NA 500/85 | 850 | 750 | 1000 | 750 | 500 | 1410 | 1950 | 1960 | 30 | 3-phase | 1150 | 180 | 900 | 210 |

| NA 675/85 | 850 | 750 | 1200 | 750 | 675 | 1410 | 2150 | 1960 | 30 | 3-phase | 1360 | 210 | 900 | 210 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher 3Approx. information in empty furnace 4Additional equipment | ||||||||||||||