Камерные печи с циркуляцией воздуха с электрическим обогревом

Оптимальное распределение воздуха за счет высоких скоростей потока.

Функции и оборудование

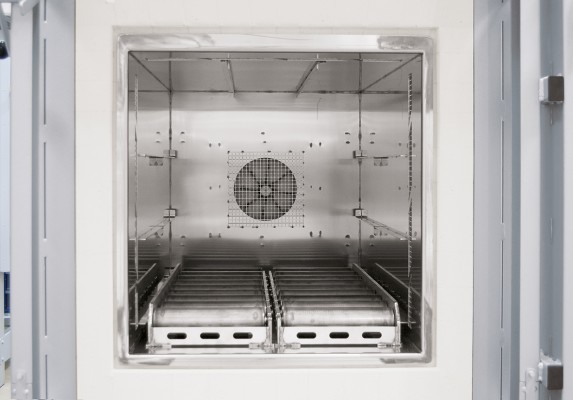

Камерная печь с циркуляцией воздуха NA 120/65

Камерная печь с циркуляцией воздуха NA 60/85 с подъемной дверью с ручным приводом и газационной камерой для фронтальной загрузки

Камерная печь с циркуляцией воздуха NA 250/85

Термоэлементный ввод

Вставной щиток

Рольганг в печном пространстве

Additional Equipment for Models Tmax up to 450 °C

- Air inlet and exhaust air flaps when used for drying

- Controlled cooling with Controller P570, for example, to relieve stresses in glass at low cooling rates (optional: PLC with controlled cooling and optimized control accuracy for cooling rates as low as 0.2 °C per hour)

- Additional frame sheet

- Gas supply boxes for different charging methods

- Gas feed fittings

- Charge control with documentation of the charge thermocouple

- Signal tower

- Feed and charging aids

- Safety technology according to EN 1539 (models NA .. LS) for charges containing solvents

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Further Additional Equipment for Models Tmax up to 650 °C and 850 °C

- Optimization of the temperature uniformity up to +/− 3 °C according to DIN 17052-1 in the empty work space

- Measuring frames and thermocouples for TUS measurements charge or comparative measurements

- Version according to AMS2750H or CQI-9

- Manual lift door for forced convection chamber furnace NA 120/65 and NA 120/85

- Pneumatic lift door from forced convection chamber furnace NA 250/65 upwards

- Manual roller conveyor in furnace chamber for high charge weights

Дополнительное оборудование

Additional Equipment (not for Models NAT ..)

- Optimization of the temperature uniformity up to +/− 3 °C according to DIN 17052-1 in the empty work space

- Air inlet and exhaust air flaps when used for drying

- Controlled cooling with Controller P570, for example, to relieve stresses in glass at low cooling rates (optional: PLC with controlled cooling and optimized control accuracy for cooling rates as low as 0.2 °C per hour)

- Manual lift door for forced convection chamber furnace NA 120/65 and NA 120/85

- Pneumatic lift door from forced convection chamber furnace NA 250/65 upwards

- Air circulation with speed control, recommendable for processes with light or sensitive charge

- Additional frame sheet

- Gas supply boxes different charging methods

- Feed and charging aids

- Safety technology according to EN 1539 (models NA .. LS) for charges containing solvents

- Furnaces in DB design with fresh air preheating, exhaust gas fan, and extensive safety package for processes with low evaporation rates of organic material

- Inlets, measuring frames and thermocouples for TUS measurements charge or comparative measurements

- Charge control with documentation of the charge thermocouple

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Спецификации

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating | Electrical | Weight | Heat-up time3 | Cool-down time3 from Tmax | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| power | to Tmax | to 150 °C in minutes | ||||||||||||

| °C | w | d | h | in l | W | D | H | in kW2 | connection | in kg | in minutes | Flaps4 | Fan cooling4 | |

| NA 120/45 | 450 | 450 | 600 | 450 | 120 | 1075 | 1475 | 1500 | 9 | 3-phase | 280 | 60 | 90 | 30 |

| NA 250/45 | 450 | 600 | 750 | 600 | 250 | 1250 | 1660 | 1670 | 12 | 3-phase | 650 | 60 | 120 | 30 |

| NA 500/45 | 450 | 750 | 1000 | 750 | 500 | 1400 | 1910 | 1810 | 18 | 3-phase | 800 | 90 | 240 | 45 |

| NA 120/45 LS | 450 | 450 | 600 | 450 | 120 | 1250 | 1550 | 1950 | 18 | 3-phase | 450 | 60 | - | - |

| NA 250/45 LS | 450 | 600 | 750 | 600 | 250 | 1350 | 1650 | 2080 | 24 | 3-phase | 520 | 60 | - | - |

| NA 500/45 LS | 450 | 750 | 1000 | 750 | 500 | 1550 | 1900 | 2220 | 24 | 3-phase | 730 | 90 | - | - |

| NA 60/65 | 650 | 350 | 500 | 350 | 60 | 930 | 1310 | 1435 | 9 | 3-phase | 240 | 90 | 210 | 30 |

| NA 120/65 | 650 | 450 | 600 | 450 | 120 | 1030 | 1410 | 1535 | 12 | 3-phase | 280 | 90 | 240 | 60 |

| NA 250/65 | 650 | 600 | 750 | 600 | 250 | 1250 | 1700 | 1750 | 20 | 3-phase | 650 | 90 | 480 | 60 |

| NA 500/65 | 650 | 750 | 1000 | 750 | 500 | 1400 | 1950 | 1900 | 27 | 3-phase | 850 | 90 | 600 | 90 |

| NA 60/85 | 850 | 350 | 500 | 350 | 60 | 930 | 1310 | 1435 | 9 | 3-phase | 315 | 150 | 480 | 90 |

| NA 120/85 | 850 | 450 | 600 | 450 | 120 | 1030 | 1410 | 1535 | 12 | 3-phase | 390 | 150 | 480 | 120 |

| NA 250/85 | 850 | 600 | 750 | 600 | 250 | 1260 | 1700 | 1810 | 20 | 3-phase | 840 | 180 | 900 | 180 |

| NA 500/85 | 850 | 750 | 1000 | 750 | 500 | 1410 | 1950 | 1960 | 30 | 3-phase | 1150 | 180 | 900 | 210 |

| NA 675/85 | 850 | 750 | 1200 | 750 | 675 | 1410 | 2150 | 1960 | 30 | 3-phase | 1360 | 210 | 900 | 210 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher 3Approx. information in empty furnace 4Additional equipment | ||||||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

В нашем каталоге «Волоконная оптика/стекло» представлен полный обзор нашего обширного ассортимента печей с выдвижным подом, колпаковых печей, печей для расплавления стекла и остальных моделей для обработки стекла.