Высокотемпературные трубчатые печи с нагревательными стержнями из карбида кремния до 1600 °C

Активное охлаждение корпуса для низких температур поверхности.

Функции и оборудование

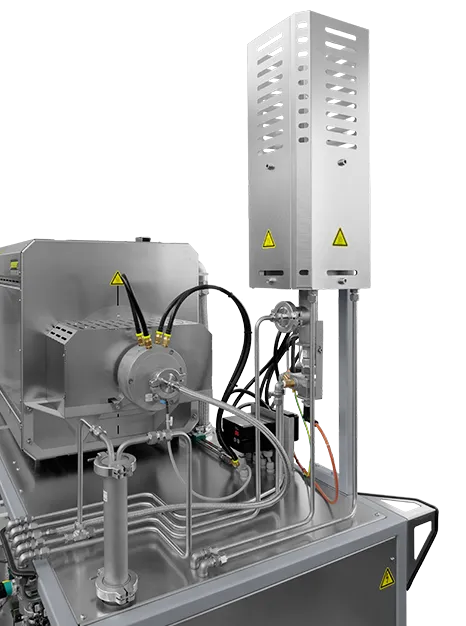

Трубчатая печь RHTC 80/450/16

Трубчатая печь RHTC 80/230/16 с пакетом для газации 2

Нагрев с помощью стержней из карбида кремния

Термоэлемент для регулирования температуры садки

These compact tube furnaces with SiC rod heating and integrated switchgear with controller can be used universally for many processes. They represent an inexpensive variant in the high-temperature range. The standard mounting options for accessories make them flexible in use for a wide range of applications. The SiC heating elements arranged parallel to the working tube provide for an excellent temperature uniformity.

Standard Equipment

- Tmax 1600 °C

- Working temperature 1500 °C, increased wear and tear must be expected in case of working at higher temperatures

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Active cooling of housing for low surface temperatures

- Ceramic working tube C 799 including two fiber plugs for operation under air

- Type S thermocouple

- Solid state relays provide for lownoise operation

- SiC heating elemens, easy to replace

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P580 (50 programs with each 40 segments)

Дополнительное оборудование

Additional Equipment

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Charge control with temperature measurement in the working tube

- Gas supply systems 1, 2 or 4

- Process control and documentation via VCD software package for monitoring, documentation and control

Спецификации

| Model | Tmax1 | Outer dimensions2 in mm | Outer tube Ø | Heated length | Length constant | Tube length | Connected | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| in °C | W | D | H | in mm | in mm | temperature1, 6 +/− 5 K in mm | in mm | load7 in kW | connection | in kg | |

| RHTC 80/230/16 | 16005 | 600 | 440 | 585 | 80 | 230 | 120 | 600 | 7.4 | 3-phase3 | 50 |

| RHTC 80/450/16 | 1600 | 820 | 440 | 585 | 80 | 450 | 210 | 830 | 11.0 | 3-phase4 | 70 |

| RHTC 80/710/16 | 1600 | 1075 | 440 | 585 | 80 | 710 | 345 | 1080 | 13.4 | 3-phase4 | 90 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Heating only between phase 1 and neutral5For standard equipment 4Heating only between two phases 6For standard equipment. Tmax 1500 °C with gas supply systems 7The connected load refers to the standard furnace and may increase for a furnace with additional equipment. For furnaces with connection options for multi-range voltages, the connected load applies to the highest permissible connected voltage. | |||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента печей, сушильных шкафов и принадлежностей для лабораторных помещений вы найдете в нашем каталоге «Лаборатория».