Компактные трубчатые печи до 1300 °C

Печи стандартно оснащаются рабочей керамической трубой С 530 и двумя волокнистыми пробками. Очень хорошее соотношение цены и производительности этих трубчатых печей является крайне убедительным.

Функции и оборудование

Трубчатая печь R 170/1000/13

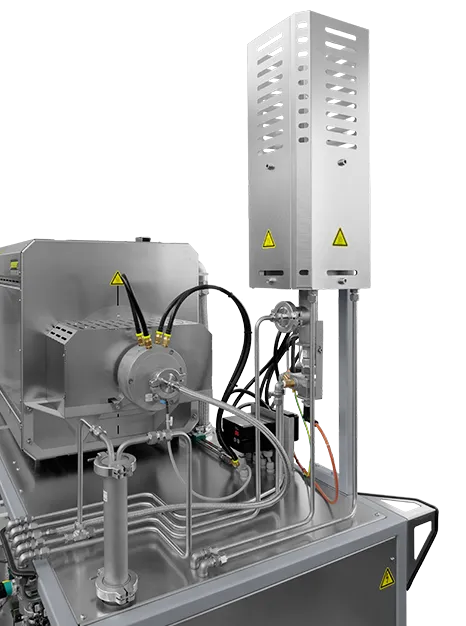

Трубчатая печь R 50/250/13 с пакетом подачи газа 2

Трубчатая печь R 50/500/12 в трехзонном исполнении

Газовая панель для негорючего защитного или реакционного газа (N2, Ar, He, CO2, воздух, формовочный газ)

Gas panel for one non-flammable process gas (N2, Ar, He, air, forming gas)

These compact tube furnaces with integrated control systems can be used universally for many processes. Equipped with a standard working tube of C 530 ceramic and two fiber plugs, these tube furnaces have a very good price/performance ratio.

Standard Equipment

- Tmax 1200 °C or 1300 °C

- Single-zoned design

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Outer tube diameter of 50 mm to 170 mm, heated length from 250 mm to 1000 mm

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Thermocouple type N (1200 °C) or type S (1300 °C)

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation B510 (5 programs with each 4 segments)

Дополнительное оборудование

Additional Equipment

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Charge control with temperature measurement in the working tube

- Three-zoned design (heated length from 500 mm) for optimization of temperature uniformity

- Gas supply systems 1, 15, 2 or 4

- Process control and documentation via VCD software package for monitoring, documentation and control

Спецификации

| Model | Tmax1 | Outer dimensions3 in mm | Outer tube Ø | Heated | Length constant1 | Tube length | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| length | temperature +/− 5 K in mm | load4 | ||||||||||

| in °C | W2 | D | H | in mm | in mm | single-zoned | three-zoned | in mm | in kW | connection | in kg | |

| R 50/250/12 | 1200 | 434 | 340 | 508 | 50 | 250 | 80 | - | 450 | 1.9 | 1-phase | 22 |

| R 50/500/12 | 1200 | 670 | 340 | 508 | 50 | 500 | 170 | 250 | 700 | 3.4 | 1-phase | 34 |

| R 120/500/12 | 1200 | 670 | 410 | 578 | 120 | 500 | 170 | 250 | 700 | 6.6 | 3-phase | 44 |

| R 170/750/12 | 1200 | 920 | 460 | 628 | 170 | 750 | 250 | 375 | 1070 | 10.6 | 3-phase | 74 |

| R 170/1000/12 | 1200 | 1170 | 460 | 628 | 170 | 1000 | 330 | 500 | 1400 | 13.7 | 3-phase | 89 |

| R 50/250/13 | 1300 | 434 | 340 | 508 | 50 | 250 | 80 | - | 450 | 1.9 | 1-phase | 22 |

| R 50/500/13 | 1300 | 670 | 340 | 508 | 50 | 500 | 170 | 250 | 700 | 3.4 | 1-phase | 34 |

| R 120/500/13 | 1300 | 670 | 410 | 578 | 120 | 500 | 170 | 250 | 700 | 6.6 | 3-phase | 44 |

| R 170/750/13 | 1300 | 920 | 460 | 628 | 170 | 750 | 250 | 375 | 1070 | 12.0 | 3-phase | 74 |

| R 170/1000/13 | 1300 | 1170 | 460 | 628 | 170 | 1000 | 330 | 500 | 1400 | 13.7 | 3-phase | 89 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 2Without tube 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 4The connected load refers to the standard furnace and may increase for a furnace with additional equipment. For furnaces with connection options for multi-range voltages, the connected load applies to the highest permissible connected voltage. | ||||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента печей, сушильных шкафов и принадлежностей для лабораторных помещений вы найдете в нашем каталоге «Лаборатория».