Вращающиеся трубчатые печи для режима пакетной обработки до 1100 °C

Компактные вращающиеся трубчатые печи серии RSRB подходят для режима пакетной обработки.

Функции и оборудование

Вращающаяся трубчатая печь RSRB 80/500/11 в качестве настольной модели для пакетной обработки

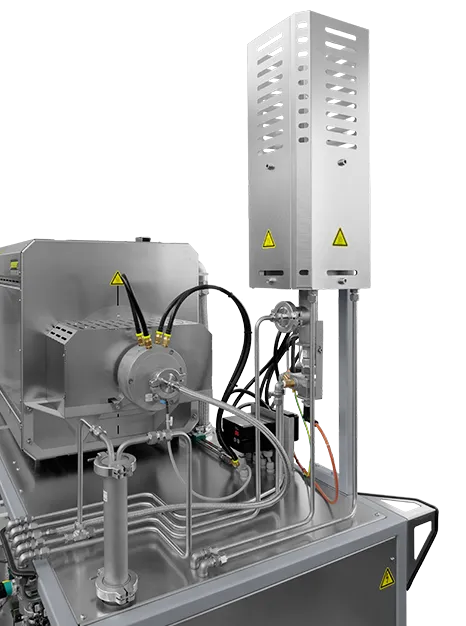

RSRB 170/1000/11 H2 con paquete de gasificación 4 para aplicación de hidrógeno

Вращающаяся трубчатая печь RSRB 120/750/11 S с левосторонним/правосторонним механизмом опрокидывания

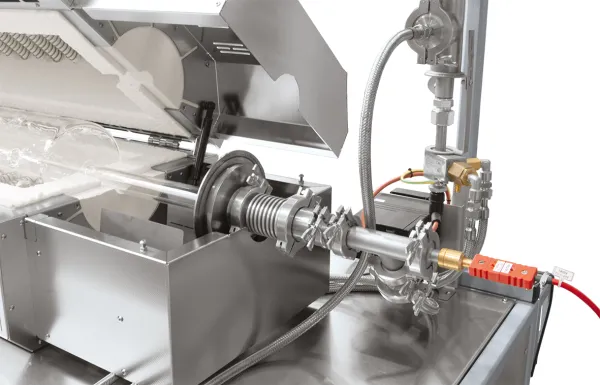

Газонепроницаемая заглушка для закрытой с одной стороны трубы из кварцевого стекла в качестве дополнительного оснащения

Газонепроницаемый поворотный ввод с газоохладителем и термоэлементом загрузки

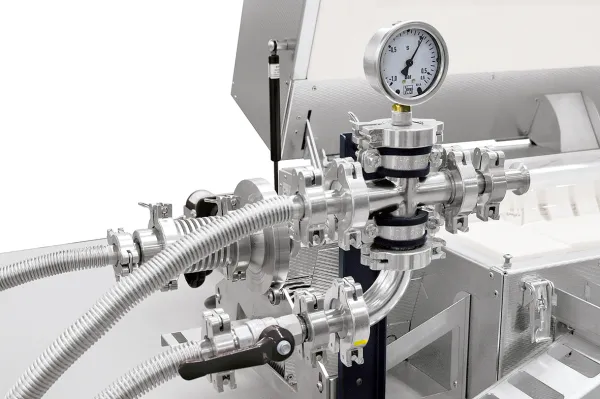

Комплект соединительных элементов для вакуумного режима

The rotary tube furnaces of the RSRB series are suited for batch operation. The rotation of the working tube ensures that the charge is in motion. Due to the shape of the quartz reactor with the tapered pipe ends the batch is kept in the rotary tube furnace and can be heat-treated an arbitrarily long time period time. A controlled heating to the temperature profiles is also possible.

Standard Equipment

- Tmax 1100 °C

- Single-zoned design

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Thermocouple type N

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- Tube furnace designed as table-top model with quartz glass reactor which opens on both sides, tapered ends

- Reactor is removed for emptying out of the rotary tube furnace. Beltless drive and hinged furnace housing (opening temperature < 180 °C) provide for very easy removal through

- Adjustable drive of approx. 1-40 rpm

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation B510 (5 prgrams with each 4 segments)

Дополнительное оборудование

Additional Equipment

- Charge control with temperature measurement in the working tube

- Three-zone control for optimization of temperature uniformity

- Reactor open on both sides, made of quartz glass with knobs for better mixing of the charge in the tube

- Gas supply system 25 for operation under non-flammable process gases with a gas-tight rotating outlet

- Gas supply package 4 for hydrogen operation

- Vacuum package for evacuating the working tube, depending on the pump used up to 10−2 mbar

- Left/right tilting device for easier loading and unloading of the work tube

- For filling, the furnace is tilted to the right to convey the batch into the furnace. After the heat treatment, the furnace is swiveled to the opposite side for emptying, in order to convey the product out of the reactor again. It is not necessary to remove the reactor.

- Mixing reactor made of quartz glass with integrated blade for better mixing of the batch, closed on one side, large opening on the opposite side

- Rotary tube furnace assembled on base with integrated switchgear and controller, incl. transport casters

- Process control and documentation via VCD software package for monitoring, documentation and control

Спецификации

| Model | Tmax1 | Outer dimensions2 in mm | Max. outer | Ø Terminal | Heated | Length constant | Tube length | Connected | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (Table-top model) | tube Ø | end | length | Temperature1 +/− 5 K in mm | load3 | in | |||||||

| in °C | W | D | H | in mm | in mm | in mm | single zoned | three zoned | in mm | in kW | connection | kg | |

| RSRB 80/500/11 | 1100 | 1200 | 445 | 580 | 76 | 28 | 500 | 170 | 250 | 1140 | 6.6 | 3-phase | 100 |

| RSRB 80/750/11 | 1100 | 1450 | 495 | 630 | 76 | 28 | 750 | 250 | 375 | 1390 | 10.6 | 3-phase | 115 |

| RSRB 120/500/11 | 1100 | 1200 | 445 | 580 | 106 | 28 | 500 | 170 | 250 | 1140 | 6.6 | 3-phase | 105 |

| RSRB 120/750/11 | 1100 | 1450 | 495 | 630 | 106 | 28 | 750 | 250 | 375 | 1390 | 10.6 | 3-phase | 120 |

| RSRB 120/1000/11 | 1100 | 1700 | 495 | 630 | 106 | 28 | 1000 | 330 | 500 | 1640 | 13.7 | 3-phase | 125 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3The connected load refers to the standard furnace and may increase for a furnace with additional equipment. For furnaces with connection options for multi-range voltages, the connected load applies to the highest permissible connected voltage. | |||||||||||||

Запрос коммерческого предложения

Другие продукты

каталог

Полный обзор нашего обширного ассортимента печей, сушильных шкафов и принадлежностей для лабораторных помещений вы найдете в нашем каталоге «Лаборатория».