Suszarka komorowa ogrzewana elektrycznie

Wydajny system cyrkulacji powietrza zapewnia równomierność temperatury w przestrzeni użytkowej.

Funkcja i wyposażenie

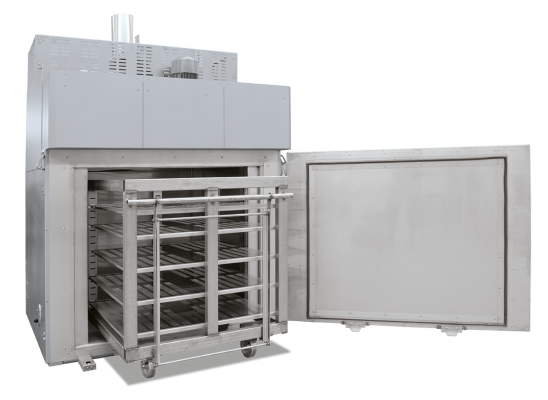

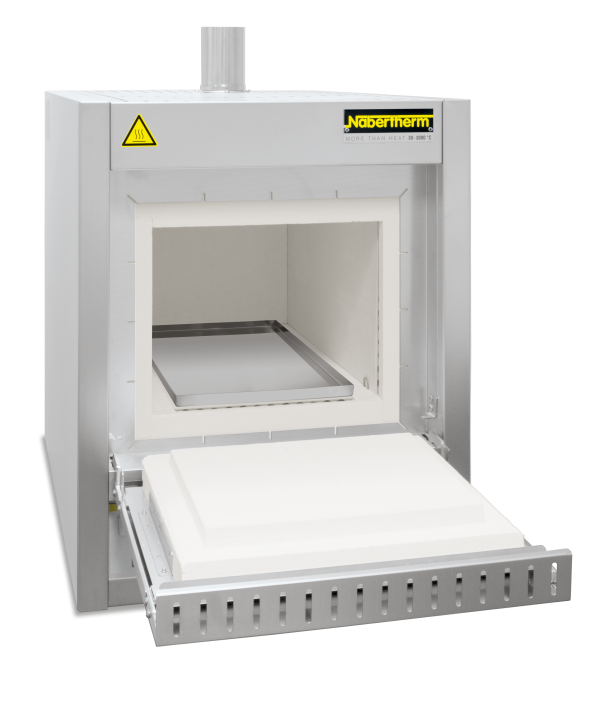

The chamber ovens of the KTR range can be used for complex drying processes and heat treatment of charges to an application temperature of 260 °C. The high-performance air circulation enables optimum temperature uniformity throughout the work space. A wide range of accessories allow the chamber ovens to be modified to meet specific process requirements.

- Tmax 260 °C

- Electrically heated (via a heating register with integrated chrome steel heating elements)

- Temperature uniformity up to +/− 3 °C according to DIN 17052-1 (for design without track cutouts)

- High-quality mineral wool insulation provides for outer temperatures of < 25 °C above room temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- High air exchange for fast drying processes

- Double-wing door for furnaces KTR 2300 and larger

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the oven and load

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Sterownik z panelem dotykowym B500 (5 programs with 4 segments each)

Dodatkowe wyposażenie

Additional Equipment

- Direct or indirect gas-fired

- Base frame to charge the oven via a charging forklift

- Additional door in the back for charging from both sides or to use the oven as lock between two rooms

- Fan system for faster cooling with manual or motor-driven control of the exhaust flaps

- Programmed opening and closing of exhaust air flaps

- Air circulation with speed control, recommendable for processes with light or sensitive charge

- Observation window and furnace chamber lighting

- Safety technology according to EN 1539 (models KTR .. LS) for charges containing solvents

- Design for clean room heat treatment processes

- Rotating systems e. g. for tempering processes

- All KTR-models are also available with Tmax 300 °C

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Accessories

- Adjustable plate shutters to adapt the air guide to the charge and improve temperature uniformity

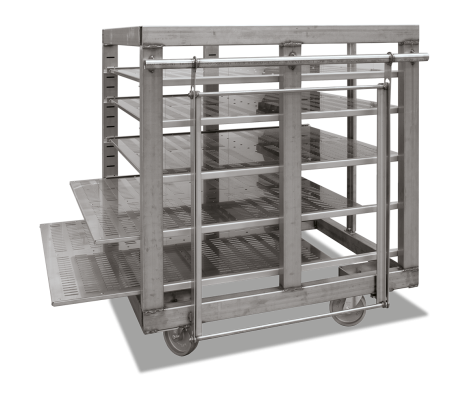

- Guide-in tracks and shelves

- Shelves with 2/3 extraction with evenly distributed load on the whole shelve surface

- Platform cart in combination with drive-in tracks

- Charging cart with rack system in combination with drive-in tracks

- Sealing shoes for ovens with drive-in tracks to improve temperature uniformity in the work space

Specyfikacja techniczna

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating power in kW1 | Electrical | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

°C | w | d | h | in l | W | D | H | KTR | KTR .. LS | connection* | |

KTR 1000 (LS) | 260 | 1000 | 1000 | 1000 | 1000 | 1820 | 1430 | 1890 | 18 | 36 | 3-phase |

KTR 1500 (LS) | 260 | 1000 | 1000 | 1500 | 1500 | 1820 | 1430 | 2390 | 18 | 36 | 3-phase |

KTR 2000 (LS) | 260 | 1100 | 1500 | 1200 | 2000 | 1920 | 1930 | 2090 | 18 | 36 | 3-phase |

KTR 2300 (LS) | 260 | 1250 | 1250 | 1500 | 2300 | 2120 | 1680 | 2460 | 27 | 36 | 3-phase |

KTR 3100 (LS) | 260 | 1250 | 1250 | 2000 | 3100 | 2120 | 1680 | 2960 | 27 | 45 | 3-phase |

KTR 3400 (LS) | 260 | 1500 | 1500 | 1500 | 3400 | 2370 | 1930 | 2460 | 45 | 54 | 3-phase |

KTR 4500 (LS) | 260 | 1500 | 1500 | 2000 | 4500 | 2370 | 1930 | 2960 | 45 | 54 | 3-phase |

KTR 4600 (LS) | 260 | 1750 | 1750 | 1500 | 4600 | 2620 | 2175 | 2480 | 45 | 54 | 3-phase |

KTR 6000 (LS) | 260 | 2000 | 2000 | 1500 | 6000 | 2870 | 2430 | 2460 | 54 | 54 | 3-phase |

KTR 6125 (LS) | 260 | 1750 | 1750 | 2000 | 6125 | 2620 | 2175 | 2980 | 45 | 63 | 3-phase |

KTR 6250 (LS) | 260 | 1250 | 2500 | 2000 | 6250 | 2120 | 3035 | 2960 | 54 | 63 | 3-phase |

KTR 8000 (LS) | 260 | 2000 | 2000 | 2000 | 8000 | 2870 | 2430 | 2960 | 54 | 81 | 3-phase |

KTR 9000 (LS) | 260 | 1500 | 3000 | 2000 | 9000 | 2490 | 3870 | 2920 | 72 | 90 | 3-phase |

KTR 12300 (LS) | 260 | 1750 | 3500 | 2000 | 12300 | 2620 | 4350 | 2980 | 90 | 108 | 3-phase |

KTR 13250 (LS) | 260 | 1250 | 5000 | 2000 | 13250 | 2120 | 6170 | 2960 | 108 | 108 | 3-phase |

KTR 16000 (LS) | 260 | 2000 | 4000 | 2000 | 16000 | 2870 | 4850 | 2960 | 108 | 120 | 3-phase |

KTR 21300 (LS) | 260 | 2650 | 3550 | 2300 | 21300 | 3600 | 4195 | 3380 | 108 | 120 | 3-phase |

KTR 22500 (LS) | 260 | 2000 | 4500 | 2500 | 22500 | 3140 | 5400 | 3500 | 108 | 120 | 3-phase |

1Depending on furnace design connected load might be higher | |||||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców do obróbki cieplnej materiałów wytwarzanych metodą 3D można znaleźć w naszym katalogu „Produkcja addytywna”.