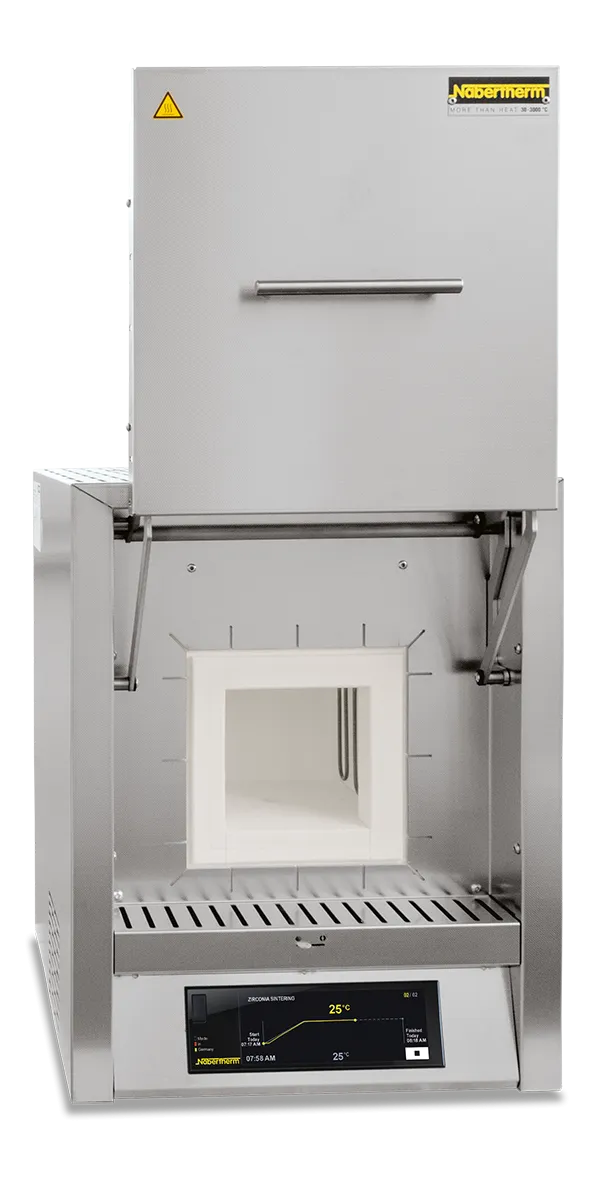

Designed as tabletop models, these compact high-temperature furnaces have a variety of advantages. The first-class workmanship using high-quality materials, combined with ease of operation, make these furnaces all-rounders in research, for example, to melt small glass samples.

- Tmax 1600 °C, 1750 °C, or 1800 °C

- Recommended working temperature 1750 °C (for models LHT ../18), increased wear and tear must be expected in case of working at higher temperatures

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- High-quality heating elements made of molybdenum disilicide offer very good protection against chemical interaction between charge and heating elements

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Adjustable air inlet opening, exhaust air opening in the roof

- Thermocouple type B or type S (LHT ../17 D)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P580 (50 programs with each 40 segments)