Funkcja i wyposażenie

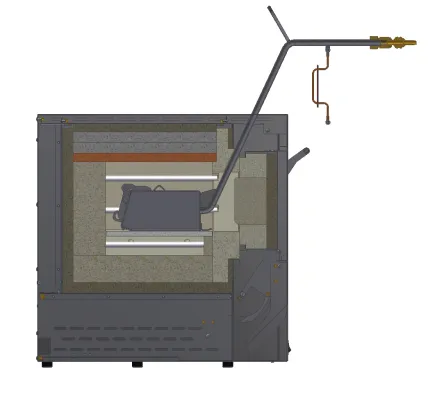

For heat treatment of small amounts of bulk material or small parts under protective gases with subsequent fast quenching in oil or water, we recommend to use protective gas boxes with a hinged lid. Boxes with an angled hinged lid on the front are equipped with a protective gas line on the rear wall. The supply line is run through the upper furnace collar. After preflushing the box with non-flammable protective and reactive gases such as argon, nitrogen or forming gas 95/5, the box is placed with hinged lid first into the furnace. Due to a slight overpressure within the box the protective gas is vented off through the hinged lid. After the heat treatment the box is taken out of the furnace and the charge is poured into quenching bath directly out of the box. By placing the box at an angle the hinged lid opens by itself. The contact with ambient air is reduced to a minimum.

- Tmax 1100 °C

- For non-combustible protective and reactive gases argon, nitrogen and forming gas (observe national regulations)

- Protective gas box with flap lid and gas supply from the rear wall

- Protective gas connection via quick coupling with hose connector (inner diameter 9 mm)

- Piping for gas inlet and outlet through the furnace collar

- Lid remains closed through its own weight

- Holder with hand handle

- Heat-resistant alloy 314 (AISI)/(DIN material no. 1.4841)

- Charge thermocouple type K for temperature display or charge control

Dodatkowe wyposażenie

Additional equipment

- Starting from N 31/H a charging cart is recommended

- Digital temperature display

- Gas supply systems

Specyfikacja techniczna

| Article no. | Furnace | Inner dimensions in mm | Outer dimensions in mm1 | Preflush rate | Process flush rate | ||||

|---|---|---|---|---|---|---|---|---|---|

| w | d | h | W | D | H | l/min | l/min | ||

| 631000964 | N 7/H | 180 | 160 | 90 | 216 | 210 | 110 | 15 - 20 | 5 - 8 |

| 631000969 | N 11/H, N 11/HR | 180 | 260 | 90 | 216 | 310 | 110 | 15 - 20 | 5 - 8 |

| 631000974 | N 17/HR | 180 | 410 | 90 | 216 | 460 | 110 | 15 - 20 | 5 - 8 |

| 631000979 | N 31/H | 260 | 220 | 120 | 290 | 272 | 140 | 20 - 25 | 10 - 15 |

| Work space = box inner dimensions: - 30 mm to all sides1 Without piping Larger boxes and custom dimensions available upon request |

|||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców i akcesoriów przeznaczonych do różnych procesów prowadzonych w atmosferze gazów reakcyjnych palnych i niepalnych, w kąpieli solnej lub w próżni można znaleźć w naszym katalogu „Technologia procesów termicznych 2”.