Chamber Furnaces, Sheet Metal Preheating Furnaces electrically heated

They are ideally suited for forming processes such as forging or hot forming steel sheets.

Function and equipment

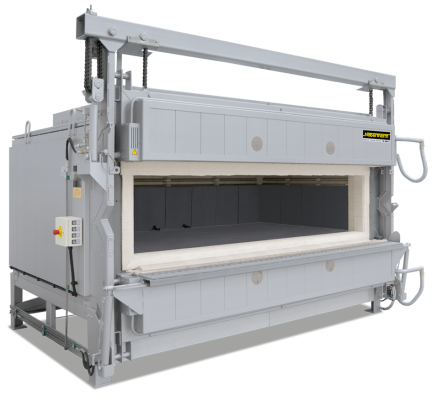

Chamber furnace with electro-hydraulic lift door on transportable base for preheating of large steel sheets for the automotive industry.

Chamber furnace N 1491/S in production

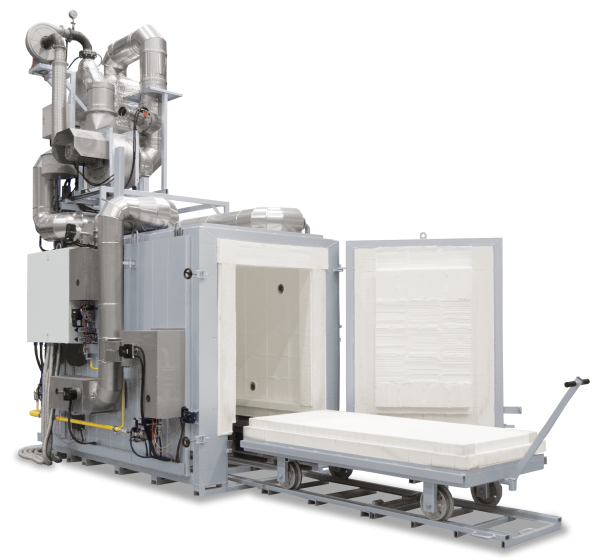

Furnace to preheat the press ram of a hot forging plant

Split lifting door for faster door openings and process gas management

Chamber furnace N 6080/13S preheating furnace for forging; with door-in-door

Furnace chamber with optional heating elements in the ceiling when used for preheating of sheetmetal plates

These very rugged chamber furnaces with radiation heating are designed for continuous heat-treatment processes. They are ideally suited for forming processes such as forging or hot forming steel sheets. The use of a wide variety of accessories enables these furnaces to be tailored to the relevant application.

- Tmax 1200 °C

- Very rugged design

- Five-sided heating from both sides, bottom, rear wall and door

- Heating elements installed on ceramic support tubes enable unimpaired heat radiation

- Bottom heating protected by heat-conducting SiC plate

- Manual lift door for chamber furnaces to N 951

- Electro-hydraulic lift door for chamber furnaces from N 1296

- Temperature uniformity up to +/− 7.5 °C according to DIN 17052-1

- Closable measuring port for customer's temperature measuring system

- Holding time measurement for the charge until it goes to forging or forming of steel sheets: After charging, the operator presses a key and the previously defined holding time for the load begins to run. The end of the holding time is indicated by both acoustic and optical signals, meaning that the charge can be removed.

- Heat resistant zinc paint for protection of door and door frame

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation B500 (5 programs with 4 segments each)

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional equipment

- Other temperatures on request

- SiC plates to protect the wall heating elements

- Electro-hydraulic lift door for models to N 951

- Protective gas ports in combination with silicone sealing of the chamber

- Protective gas boxes for heat treatment under non-flammable protective and reaction gases

- Loading devices and charging aids

- Charging grates for heavy loads

- Cooling fan in combination with motor-driven exhaust air flaps in the top of the furnace

- Commissioning of the furnace with test firing and temperature uniformity measurement using 11 thermocouples including record of the measurement results

- Furnace chamber with optional heating elements in the ceiling when used for preheating of sheetmetal plates

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating power | Electrical | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | in kW1 | connection | |

| N 731 | 1200 | 750 | 1300 | 750 | 730 | 1800 | 2400 | 2890 | 70 | 3-phase |

| N 761 | 1200 | 800 | 1900 | 500 | 760 | 1740 | 2700 | 2650 | 70 | 3-phase |

| N 891 | 1200 | 800 | 1400 | 800 | 890 | 1740 | 2200 | 3450 | 70 | 3-phase |

| N 951 | 1200 | 1000 | 1900 | 550 | 950 | 2060 | 2700 | 2780 | 70 | 3-phase |

| N 1296 | 1200 | 1800 | 1200 | 600 | 1296 | 2860 | 2000 | 3020 | 70 | 3-phase |

| N 1491 | 1200 | 1660 | 1200 | 750 | 1490 | 2720 | 2000 | 3350 | 110 | 3-phase |

| N 1501 | 1200 | 1000 | 1500 | 1000 | 1500 | 2060 | 2300 | 3845 | 95 | 3-phase |

| N 1601 | 1200 | 1600 | 2000 | 500 | 1600 | 2660 | 2900 | 2900 | 110 | 3-phase |

| N 1760 | 1200 | 2200 | 1600 | 500 | 1760 | 3400 | 2500 | 2900 | 110 | 3-phase |

| N 1771 | 1200 | 1400 | 1400 | 900 | 1770 | 2460 | 2200 | 3745 | 110 | 3-phase |

| N 2161 | 1200 | 1700 | 1700 | 750 | 2160 | 2760 | 2600 | 3350 | 110 | 3-phase |

| N 2201 | 1200 | 1000 | 2200 | 1000 | 2200 | 2060 | 3000 | 3845 | 150 | 3-phase |

| N 2251 | 1200 | 2500 | 1500 | 600 | 2250 | 3560 | 2300 | 3020 | 110 | 3-phase |

| N 2401 | 1200 | 2500 | 1200 | 800 | 2400 | 3560 | 2000 | 3445 | 110 | 3-phase |

| 1Depending on furnace design connected load might be higher 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

||||||||||

Request for quotation

Archivo de vídeo

Further products

Catalog

A complete overview of our extensive range of furnaces and plants that are used for heat treatment processes in air can be found in our catalog "Thermal Process Technology 1, furnaces and heat treatment plants for processes under air".