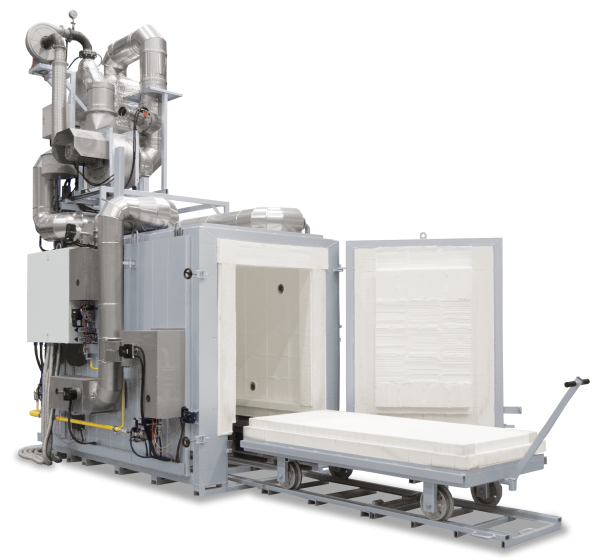

Bogie Hearth Furnaces electrically heated

When several bogies are used together with a second door or bogie transfer system, one bogie can be loaded outside the furnace while the other bogie is in the furnace.

Function and equipment

For annealing and hardening of large parts, e. g. heavy casted parts or tool steel dies to temperatures between 800 °C and 1100 °C, we recommend our bogie hearth furnaces with radiation heating. The bogie can be loaded outside the furnace. Due to the electro-hydraulic lift door and a motorized bogie (from model WS 2200/..), the furnace can be opened while hot and the load can be removed for cooling or quenching. When several bogies are used together with a second door or bogie transfer system, one bogie can be loaded outside the furnace while the other bogie is in the furnace. This shortens process times and the residual energy of the furnace can be used when the new charge is heated.

- Tmax 1000 °C or 1200 °C

- Dual shell housing provides low shell temperatures

- Electro-hydraulic lift door

- Heating from five sides (four sides and bogie) provides for a optimum temperature uniformity

- Bogie heating receives power via blade contacts when driven in

- Heating elements mounted on support tubes provide for free radiation and long service life

- Bottom heating protected by SiC tiles on the bogie providing level stacking surface

- Bogie with flanged wheels on rails, from model WS 2200/.. incl. electric drive

- Motorized exhaust air flap on the furnace roof

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P570 (50 programs with each 40 segments)

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documention of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional equipment

- Electric chain-driven bogie in combination with rail operation for smooth movement of heavy loads for models WS 1000/.. and WS 1500/..

- Bogie running on steel wheels with gear rack drive, no rails in front of the furnace necessary

- Different possibilities for an extension to a bogie hearth furnace plant:

- Additional bogies

- Bogie transfer system with parking rails to exchange bogies running on rails or to connect multiples furnaces

- Fully automatic control of the bogie exchange

- Uncontrolled or controlled cooling system with frequency-controlled cooling fan and motor-driven exhaust air flap

- Multi-zone control adapted to the particular furnace provides model for optimal the temperature uniformity

- Temperature uniformity measurement

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Heating | Electrical | Max. charging weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | W | D | H | power in kW1 | connection | in kg | |

| WS 1000/10 | 1000 | 800 | 1600 | 800 | 1000 | 1470 | 2390 | 1920 | 60 | 3-phase | 840 |

| WS 1500/10 | 1000 | 900 | 1900 | 900 | 1500 | 1570 | 2690 | 2020 | 80 | 3-phase | 1190 |

| WS 2200/10 | 1000 | 1000 | 2200 | 1000 | 2200 | 1670 | 2990 | 2120 | 105 | 3-phase | 1600 |

| WS 4000/10 | 1000 | 1200 | 2800 | 1200 | 4000 | 1870 | 3590 | 2320 | 135 | 3-phase | 2600 |

| WS 7500/10 | 1000 | 1500 | 3600 | 1400 | 7500 | 2170 | 4390 | 2520 | 200 | 3-phase | 4420 |

| WS 12000/10 | 1000 | 1700 | 5000 | 1400 | 12000 | 2370 | 5790 | 2520 | 300 | 3-phase | 7200 |

| WS 15000/10 | 1000 | 2000 | 5000 | 1500 | 15000 | 2670 | 5790 | 2620 | 415 | 3-phase | 8640 |

| WS 1000/12 | 1200 | 800 | 1600 | 800 | 1000 | 1470 | 2390 | 1920 | 80 | 3-phase | 840 |

| WS 1500/12 | 1200 | 900 | 1900 | 900 | 1500 | 1570 | 2690 | 2020 | 105 | 3-phase | 1190 |

| WS 2200/12 | 1200 | 1000 | 2200 | 1000 | 2200 | 1670 | 2990 | 2120 | 135 | 3-phase | 1600 |

| WS 4000/12 | 1200 | 1200 | 2800 | 1200 | 4000 | 1870 | 3590 | 2320 | 200 | 3-phase | 2600 |

| WS 7500/12 | 1200 | 1500 | 3600 | 1400 | 7500 | 2170 | 4390 | 2520 | 300 | 3-phase | 4420 |

| WS 12000/12 | 1200 | 1700 | 5000 | 1400 | 12000 | 2370 | 5790 | 2520 | 415 | 3-phase | 7200 |

| WS 15000/12 | 1200 | 2000 | 5000 | 1500 | 15000 | 2670 | 5790 | 2620 | 470 | 3-phase | 8640 |

| 1Depending on furnace design connected load might be higher 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. |

|||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnaces and plants that are used for heat treatment processes in air can be found in our catalog "Thermal Process Technology 1, furnaces and heat treatment plants for processes under air".