Piece z wózkiem z cyrkulacją powietrza

Są one optymalnie przystosowane do procesów takich jak odprężanie szkła lub chłodzenie szkła, w których istotna jest dobra równomierność temperatury.

Funkcja i wyposażenie

The forced convection bogie hearth furnaces W 1000/60A - W 8300/85A are used when heavy charges weighing have to be heat-treated. They are ideal for processes such as solution like glass tempering or cooling from glass, for which a good temperature uniformity is crucial. The high-performance air circulation assures that the temperature uniformity achieved throughout the work space is outstanding. A broad selection of additional equipment enables these bogie hearth furnaces to be optimally adapted to suit specific processes.

- Tmax 600 °C or 850 °C

- Dual shell housing with rear ventilation provides for low shell temperatures for the 850 °C models

- Swing door hinged on the right side

- Heating from chrome steel heating elements for the 600 °C models

- Heating from three sides (both side walls and the trolley) for the 850 °C models. Bottom heating protected by SiC tiles.

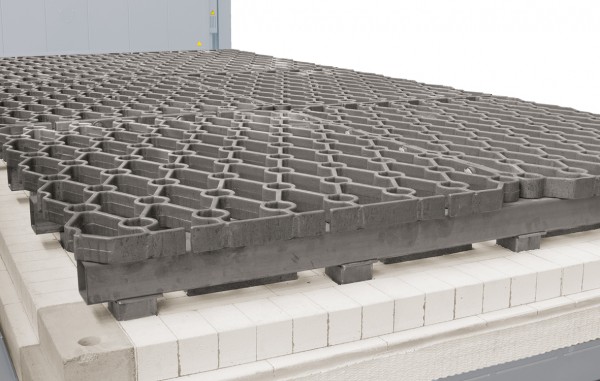

- Perforated sheet support or charging grid on the bogie for even load distribution

- High-performance air circulation fan with vertical circulation

- Temperature uniformity up to +/- 5 °C according to DIN 17052-1

- Bottom heating protected by SiC tiles on the bogie providing level stacking surface for the 850 °C models

- Insulation structured with high-quality mineral wool for 600 °C models

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Bogies with flanged wheels running on rails for easy and precise movement of heavy loads

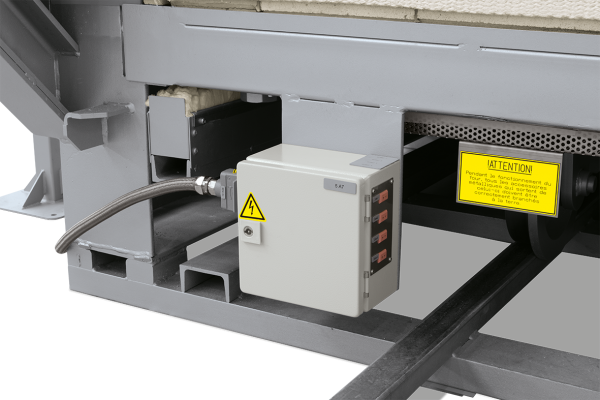

- Electric chain-driven bogie in combination with rail operation for smooth movement of heavy loads from model W 4800

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the oven and load

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation B500 (5 programs with 4 segments each)

Dodatkowe wyposażenie

- Electric chain-driven bogie in combination with rail operation for smooth movement of heavy loads up to Model W 4000

- Optimization of the temperature uniformity up +/− 3 °C according to DIN 17052-1

- Different possibilities for an extension to a bogie hearth furnace plant:

- Additional bogies

- Bogie transfer system with parking rails to exchange bogies running on rails or to connect multiples furnaces

- Motorized bogies and cross-traversal system

- Fully automatic control of the bogie exchange

- Electro-hydraulic lift door

- Motorized fresh-air and exhaust air flaps, adjustable via the program

- Cooling systems for more rapid cooling

- Bar supports or grids for higher charge weights and/or better load distribution

- Commissioning of the furnace with test firing and temperature uniformity measurement (also with load) for the purpose of process optimization

- Process control and documentation via VCD software package or Nabertherm Control Center (NCC) for monitoring, documentation and control

Specyfikacja techniczna

| Model | Tmax | Inner dimensions in mm | Volume | Max. charging weight | Outer dimensions1 in mm | Heating power | Electrical | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | w | d | h | in l | in kg | W | D | H | in kW2 | connection | |

| W 1000/.. A | 600 | 800 | 1600 | 800 | 1000 | 800 | 1780 | 2450 | 2350 | 48 | 3-phase |

| W 1600/.. A | 600 | 1000 | 1600 | 1000 | 1600 | 1000 | 1920 | 2450 | 2510 | 48 | 3-phase |

| W 2200/.. A | 600 | 1000 | 2250 | 1000 | 2200 | 1500 | 1980 | 3100 | 2560 | 96 | 3-phase |

| W 3300/.. A | 600 | 1200 | 2250 | 1200 | 3300 | 1900 | 2180 | 3100 | 2750 | 96 | 3-phase |

| W 4000/.. A | 600 | 1500 | 2250 | 1200 | 4000 | 2400 | 2480 | 3100 | 2800 | 120 | 3-phase |

| W 4800/.. A | 600 | 1200 | 3300 | 1200 | 4800 | 2800 | 2180 | 4380 | 2850 | 120 | 3-phase |

| W 6000/.. A | 600 | 1500 | 3300 | 1200 | 6000 | 3700 | 2480 | 4380 | 2900 | 144 | 3-phase |

| W 6600/.. A | 600 | 1200 | 4600 | 1200 | 6600 | 4000 | 2280 | 5680 | 2780 | 144 | 3-phase |

| W 7500/.. A | 600 | 1400 | 3850 | 1400 | 7500 | 4000 | 2380 | 4930 | 3020 | 144 | 3-phase |

| W 8300/.. A | 600 | 1500 | 4600 | 1200 | 8300 | 5200 | 2580 | 5680 | 2780 | 192 | 3-phase |

| W 1000/.. A | 850 | 800 | 1600 | 800 | 1000 | 800 | 1780 | 2450 | 2350 | 45 | 3-phase |

| W 1600/.. A | 850 | 1000 | 1600 | 1000 | 1600 | 1000 | 1920 | 2450 | 2510 | 45 | 3-phase |

| W 2200/.. A | 850 | 1000 | 2250 | 1000 | 2200 | 1500 | 1980 | 3100 | 2560 | 90 | 3-phase |

| W 3300/.. A | 850 | 1200 | 2250 | 1200 | 3300 | 1900 | 2180 | 3100 | 2750 | 90 | 3-phase |

| W 4000/.. A | 850 | 1500 | 2250 | 1200 | 4000 | 2400 | 2480 | 3100 | 2800 | 110 | 3-phase |

| W 4800/.. A | 850 | 1200 | 3300 | 1200 | 4800 | 2800 | 2180 | 4380 | 2850 | 110 | 3-phase |

| W 6000/.. A | 850 | 1500 | 3300 | 1200 | 6000 | 3700 | 2480 | 4380 | 2900 | 140 | 3-phase |

| W 6600/.. A | 850 | 1200 | 4600 | 1200 | 6600 | 4000 | 2280 | 5680 | 2780 | 140 | 3-phase |

| W 7500/.. A | 850 | 1400 | 3850 | 1400 | 7500 | 4000 | 2380 | 4930 | 3020 | 140 | 3-phase |

| W 8300/.. A | 850 | 1500 | 4600 | 1200 | 8300 | 5200 | 2580 | 5680 | 2780 | 185 | 3-phase |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Depending on furnace design connected load might be higher | |||||||||||

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców z wysuwnym trzonem, pieców kołpakowych, pieców do topienia szkła i innych modeli do obróbki szkła można znaleźć w naszym katalogu „Technika światłowodowa / Szkło”.