Funkcja i wyposażenie

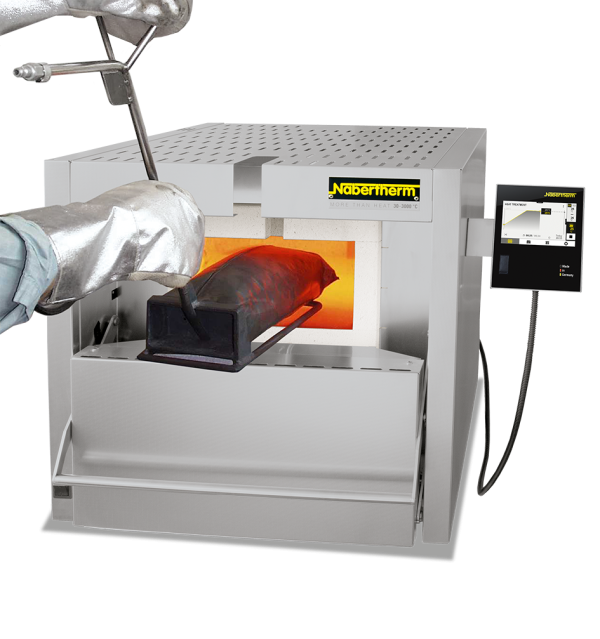

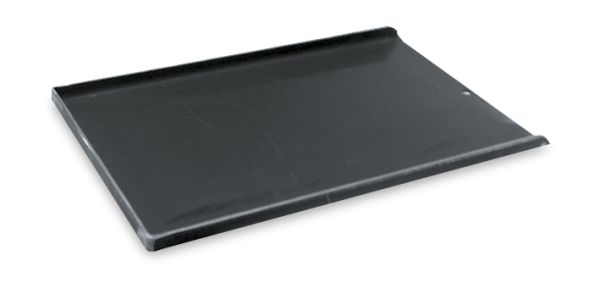

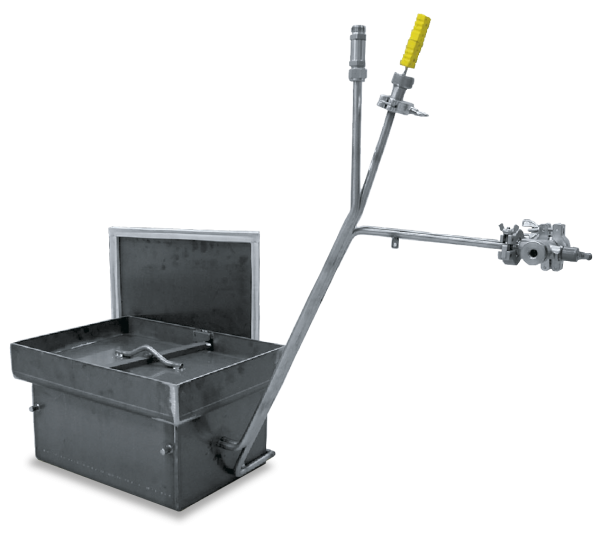

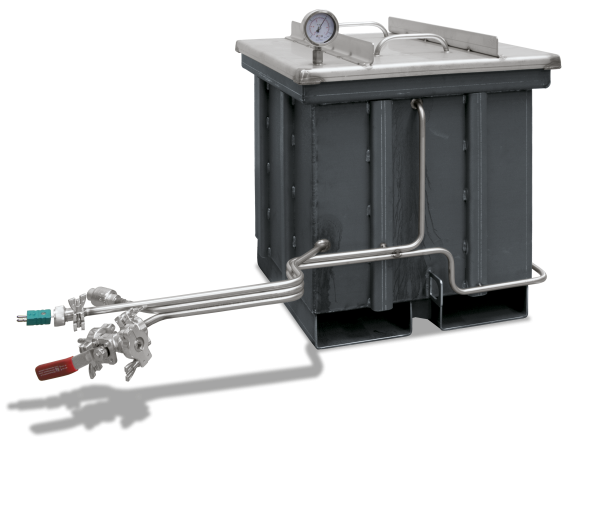

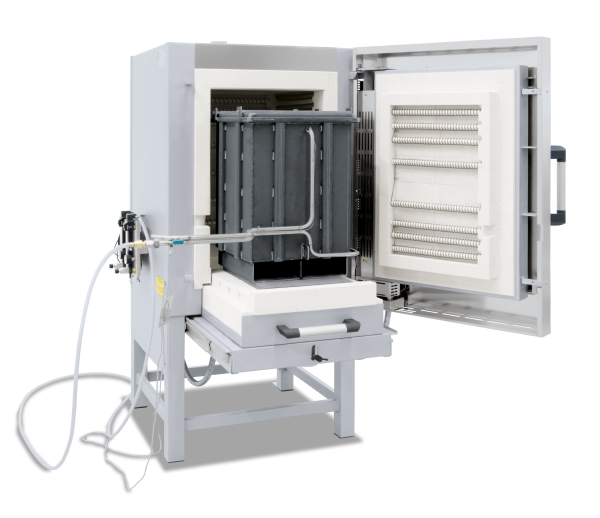

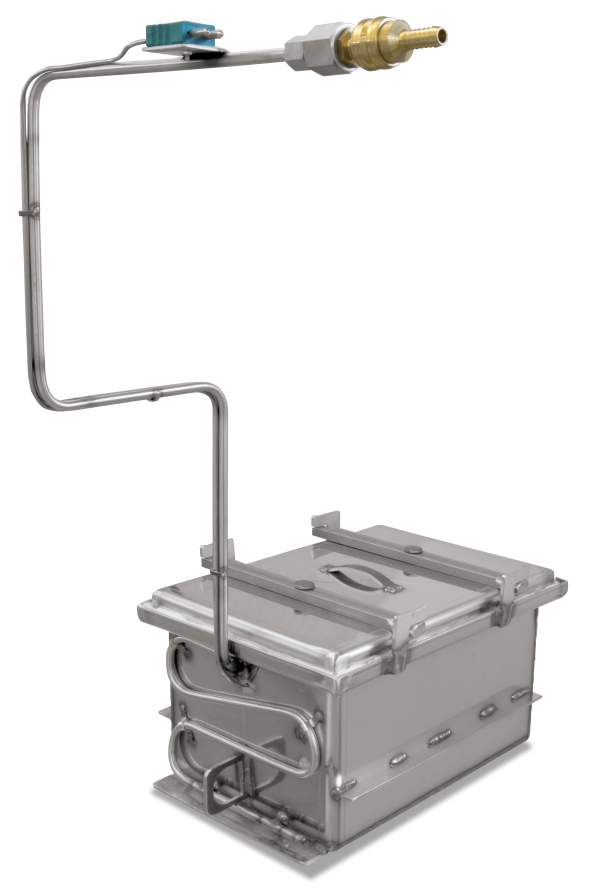

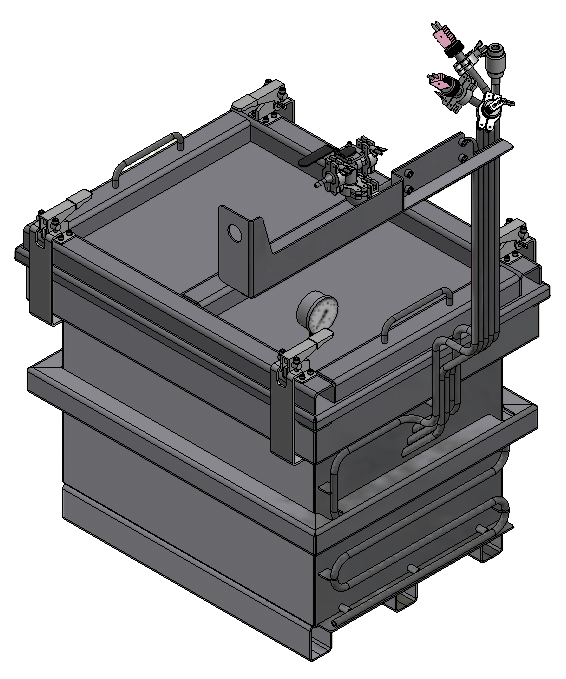

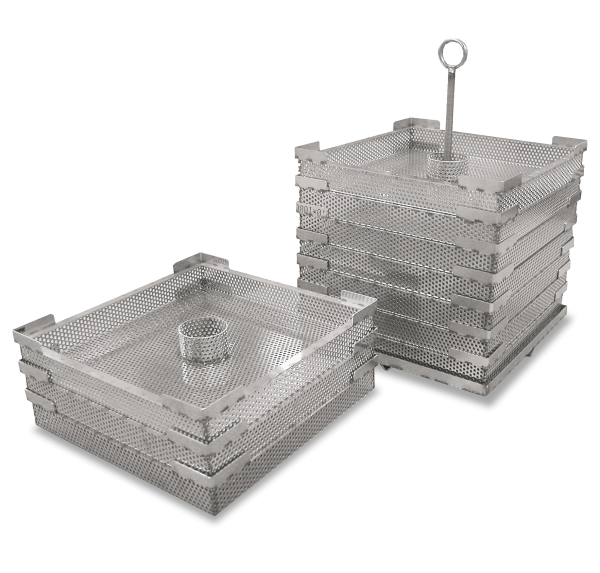

When workpieces made of air-hardened steel must be heat treated under protective gas and quenched afterwards, the protective gas annealing bag with holder is an optimal solution. This system consists of a holder with charge carrier and protective gas tube as well as a bag made of stainless steel heat treating foil.

The charge is placed on the charge carrier and covered with the protective gas annealing bag. The bag is preflushed with non-flammable protective and reactive gases such as argon, nitrogen or forming gas 95/5 and placed together with the holder in the furnace. After the charge has been heated, the protective gas annealing bag and holder are removed from the furnace and cooled with the help of the forced cooling system or in still air. At the same time the workpiece remains in the bag in the protective gas atmosphere. This prevents oxidation from occuring. Due to thin-walled foil very rapid cooling times can be achieved.

The protective gas annealing bag is also suitable for quenching workpieces in oil or water. The protective gas annealing bag with holder is taken out of the hot furnace after the heating time. The bag is pulled off the holder above the quenching bath using a heat protection glove. After this the workpiece can slide directly into the quenching bath. The short exposure to ambient air while being pulled out normally has only minimum effect on the surface oxidation of workpieces.

The bags can be used multiple times. Our experience shows that at temperatures < 950 °C the stainless steel heat treating bag lasts for approx. 10 - 15 processes. At temperatures between 950 °C and 1050 °C, use for approx. 5 - 10 processes can be assumed.

- Tmax 1100 °C

- For non-combustible protective and reactive gases argon, nitrogen and forming gas (observe national regulations)

- Holder with protective gas annealing bag

- Supplied with three protective gas annealing bags

- Protective gas supply with quick lock and hose connector (inner diameter 9 mm)

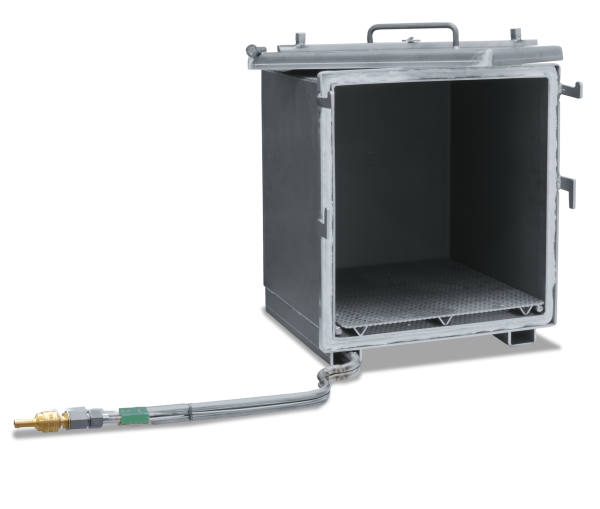

- Protective protective gas through notch in upper furnace collar

- Holder with hand handle

- Heat-resistant alloy 314 (AISI)/(DIN material no. 1.4841)

- Charge thermocouple type K for temperature display or charge control

Dodatkowe wyposażenie

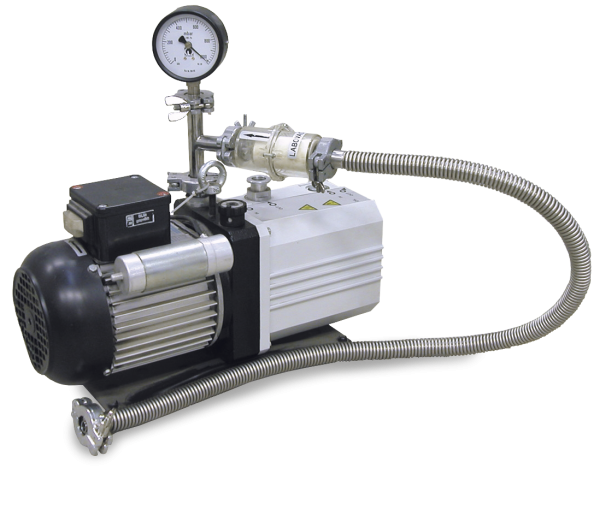

Additional equipment

- Starting from N 31/H a charging cart is recommended

- Digital temperature display

- Gas supply systems

Specyfikacja techniczna

| Article no. | Furnace | Useable inner dimensions in mm | Replacement bag | Bag dimensions in mm | Preflush rate | Process flush rate | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| w | d | h | (article no.) | w | d | h | l/min | l/min | ||

| 631000539 | N 7/H | 60 | 180 | 30 | 491040825 | 60 | 180 | 30 | 15 - 20 | 5 - 8 |

| 631000540 | N 11/H, N 11/HR | 100 | 180 | 50 | 491042225 | 100 | 180 | 50 | 15 - 20 | 5 - 8 |

| 631000541 | N 17/HR | 100 | 280 | 50 | 491042235 | 100 | 280 | 50 | 15 - 20 | 5 - 8 |

| 631000542 | N 31/H | 100 | 180 | 50 | 491042225 | 100 | 180 | 50 | 15 - 20 | 5 - 8 |

| 631000543 | N 41/H | 140 | 350 | 60 | 491043640 | 140 | 350 | 60 | 15 - 20 | 5 - 8 |

| 631000544 | N 61/H, N 87/H | 180 | 350 | 70 | 491045242 | 180 | 350 | 70 | 20 - 25 | 10 - 15 |

Zapytanie ofertowe

Dalsze produkty

Katalogu

Kompletny przegląd naszej szerokiej oferty pieców i akcesoriów przeznaczonych do różnych procesów prowadzonych w atmosferze gazów reakcyjnych palnych i niepalnych, w kąpieli solnej lub w próżni można znaleźć w naszym katalogu „Technologia procesów termicznych II”.