Ovens with Safety Technology

Suitable for drying charges containing solvents according to EN 1539.

Function and equipment

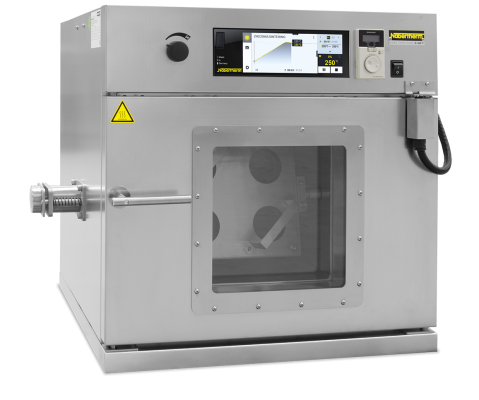

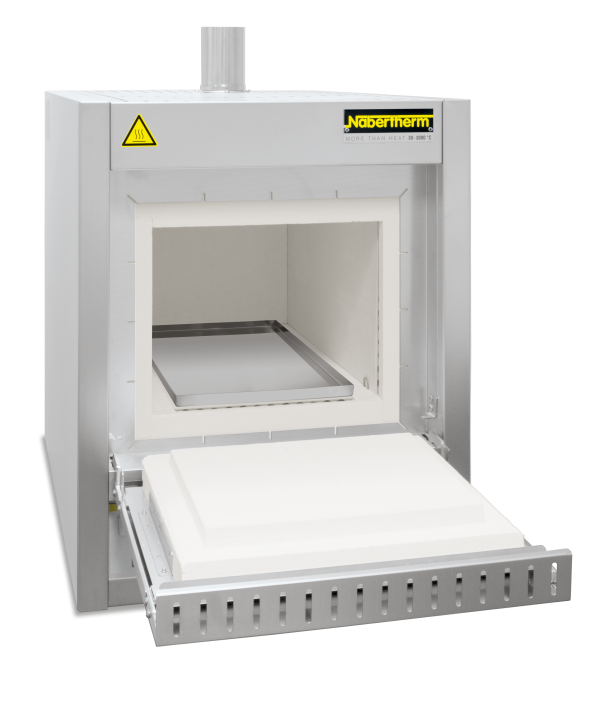

Ovens in the TR .. LS range with safety equipment based on EN 1539 Type A are suitable for drying charges containing solvents. With their compact design, these ovens can be easily integrated into a laboratory or production process. Exhaust gases escape through an outlet on the back of the oven and can then be extracted or treated.

- Furnace technology based on ovens

- For a description of the safety technology refer to models NA 120/45 LS ff.

- Tmax 260 °C

- Temperature uniformity ±8 K according to DIN 17052-1 in empty work space

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Defined application within the constraints of the operating instructions

- Controller with touch operation C550 (10 programs with 20 segments each)

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Freeware NTEdit for convenient program input via ExcelTM for WindowsTM on the PC

- Freeware NTGraph for evaluation and documentation of firings using ExcelTM for WindowsTM on the PC

- MyNabertherm App for online monitoring of the firing on mobile devices for free download

Additional equipment

- Window for charge observing

- Further removeable grids with rails

- Side inlet

- Electrical rotary device (associated sample holder will be individually adapted to the charge)

- Transport castors for models TR 240 - TR 450

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Connected load4 | Electrical | Weight | Minutes | Grids | Grids | Total load | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

°C | w | d | h | in l | W | D | H | kW | connection | in kg | to Tmax3 | incl. | max. | max.1 | |

TR 60 LS | 260 | 450 | 390 | 350 | 60 | 700 | 820 | 720 | 5.7 | 3-phase | 96 | 20 | 1 | 4 | 120 |

TR 120 LS | 260 | 650 | 390 | 500 | 120 | 900 | 820 | 870 | 6.7 | 3-phase | 140 | 22 | 2 | 7 | 150 |

TR 240 LS | 260 | 750 | 550 | 600 | 240 | 1000 | 990 | 970 | 6.7 | 3-phase | 170 | 32 | 2 | 8 | 150 |

TR 450 LS | 260 | 750 | 550 | 1100 | 450 | 1000 | 990 | 1470 | 13.4 | 3-phase | 250 | 36 | 3 | 15 | 180 |

1Maximum load per level 30 kg | |||||||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnace concepts for heat treatment after 3D printing can be found in our catalog “Additive Manufacturing”.