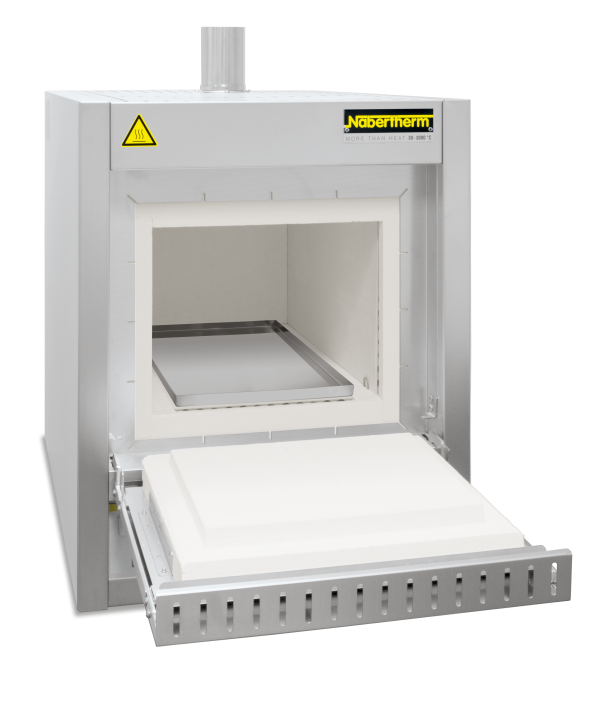

Ashing Furnaces L ../11 BO up to 1100 °C with integrated catalytic post combustion

The ashing furnaces have a passive safety system and integrated exhaust gas post combustion.

The ashing furnaces have a passive safety system and integrated exhaust gas post combustion.

The ashing furnaces L ../11 BO are specially designed for processes in which organic substances have to be evaporated from the charge, as e. g. during debinding of small ceramic products after additive manufacturing. Other processes, for which this furnace series is designed for, are for example, ashing of (food) samples, thermal cleaning of injection molding tools or loss on ignition determination.

The ashing furnaces therefore have a passive safety system and integrated exhaust gas post combustion. An exhaust gas fan extracts the exhaust gases from the furnace and simultaneously supplies fresh air to the furnace atmosphere with the result that sufficient oxygen is always available for the process. The incoming air is guided behind the furnace heating and preheated to ensure good temperature uniformity. Exhaust gases are directly led from the furnace chamber to the integrated post combustion system, where they are burned and catalytically cleaned. After the debinding/ashing process (up to max. 600 °C), a sintering process up to max. 1100 °C can be performed.

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Max. loading weight of organic substances | Max. evaporation rate of organic substances | Connected load | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

in °C1 | w | d | h | in l | W | D | H3 | in g | g/min | in kW | connection | in kg | |

L 9/11 BO | 1100 | 230 | 240 | 170 | 9 | 415 | 575 | 750 | 75 | 1.0 | 7.0 | 3-phase | 60 |

L 24/11 BO | 1100 | 280 | 340 | 250 | 24 | 490 | 675 | 800 | 150 | 2.0 | 9.0 | 3-phase | 90 |

L 40/11 BO | 1100 | 320 | 490 | 250 | 40 | 530 | 825 | 800 | 200 | 2.1 | 11.7 | 3-phase | 110 |

1Recommended working temperature for processes with longer dwell times is 1000 °C | |||||||||||||

A complete overview of our extensive range from the small laboratory furnace up to a combi furnace system for debinding and sintering in one process can be found in our catalog “Advanced Materials”.