Ashing Furnaces up to 1100 °C

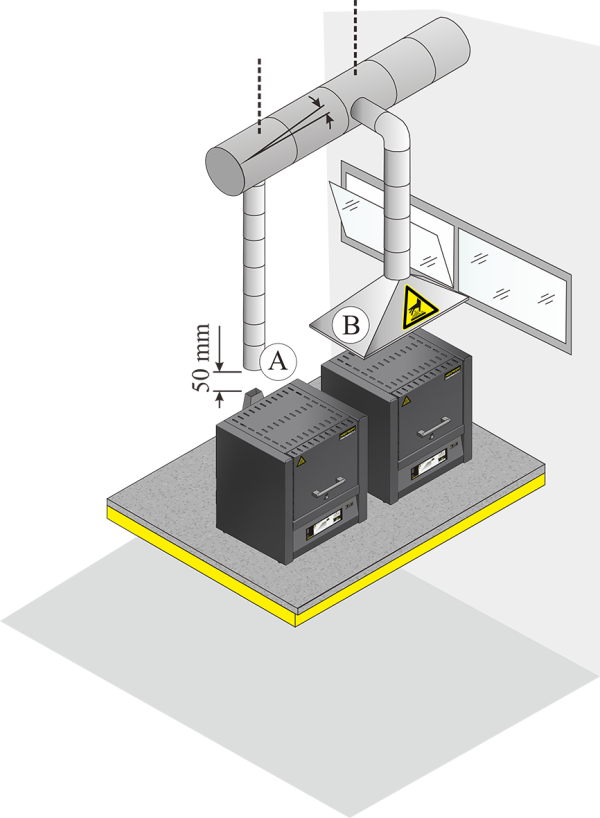

A special fresh-air and exhaust air system ensures that the air is replaced 6 times per minute so that there is always sufficient oxygen for the ashing process.

Function and equipment

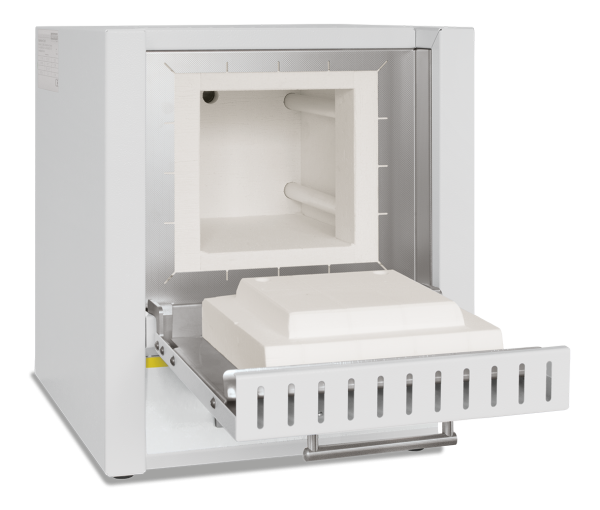

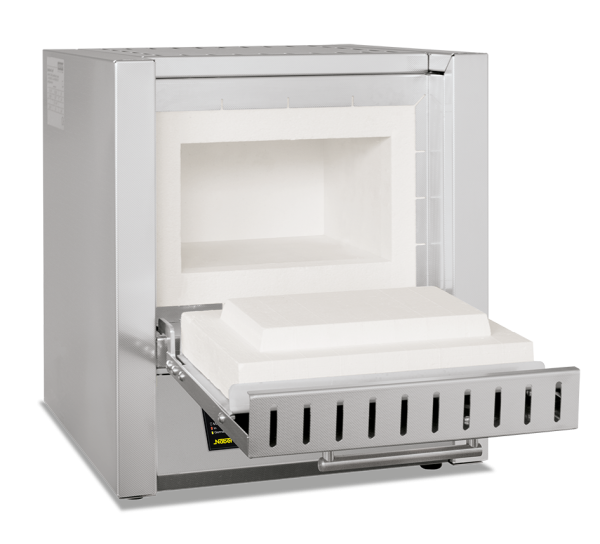

Ashing furnace LV(T) .. 11 is designed especially for ashing processes to 1050 °C in the laboratory. Applications include determining loss on ignition, ashing food and plastics for subsequent substance analysis. A special fresh-air and exhaust air system ensures that the air is replaced 6 times per minute so that there is always sufficient oxygen for the ashing process. Incoming air passes the furnace heating and is pre-heated to ensure good temperature uniformity.

Standard Equipment

- Tmax 1100 °C

- Heating from two sides

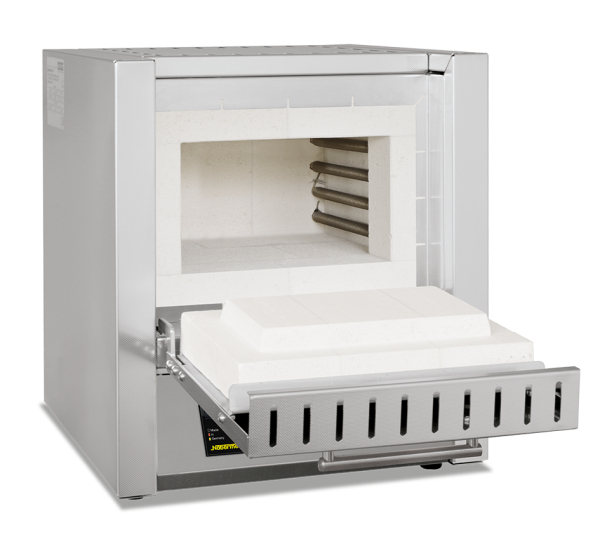

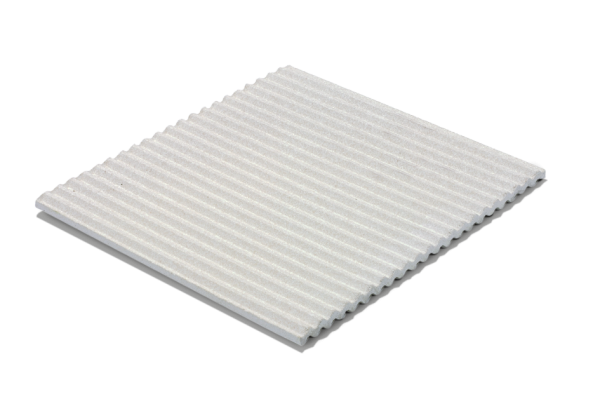

- Ceramic heating plates with integral heating element which is safeguarded, and easy to replace

- Air exchange of more than 6 times per minute

- Good temperature uniformity due to preheating of incoming air, temperature uniformity according to DIN 17052-1 to +/− 10 °C in the defined empty work area (from 550 °C)

- Dual shell housing made of textured stainless steel sheets with additional fan cooling for low surface temperature

- Exclusive use of insulation materials without categorization according to EC Regulation No. 1272/2008 (CLP)

- Suitable for many standardized ashing processes according to ISO, ASTM, EN, and DIN

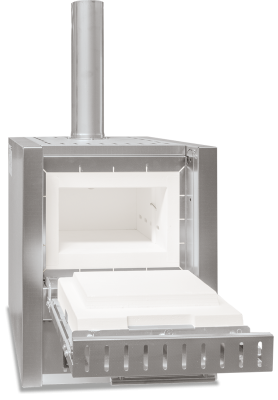

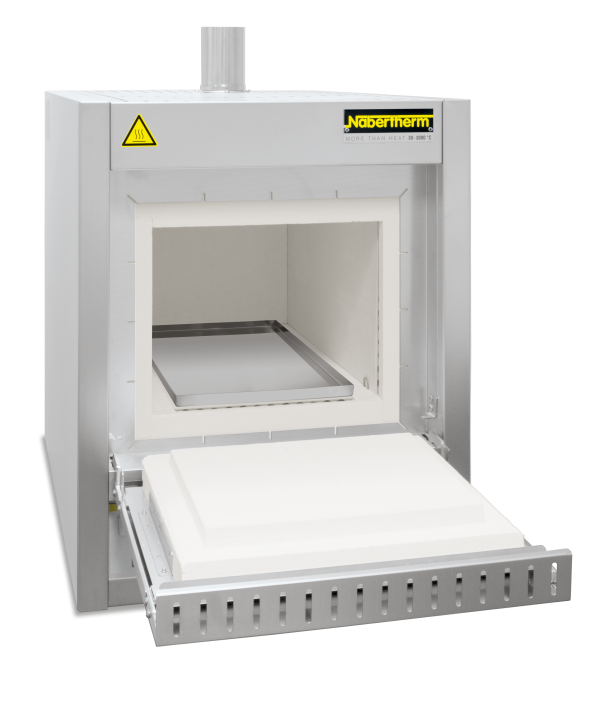

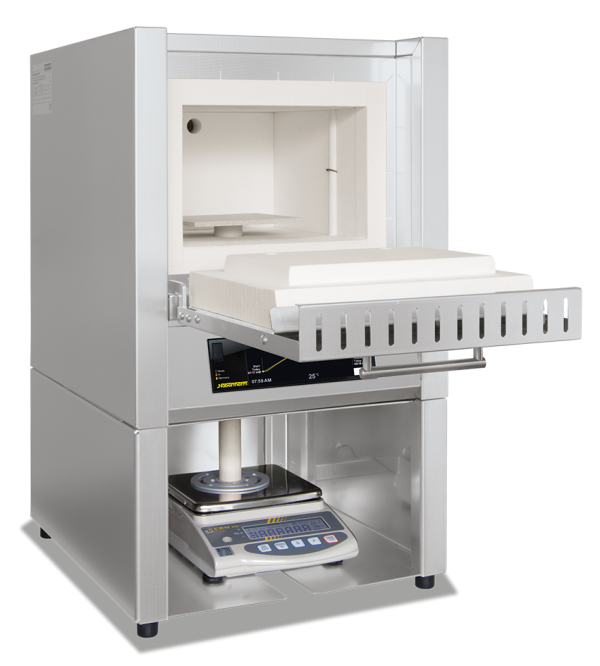

- Optional flap door (LV) which can be used as work platform or lift door (LVT) with hot surface facing away from the operator

- Controller with touch operation B510 (5 programs with each 4 segments)

- Solid state relays provide for lownoise operation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

Additional Equipment

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Port for thermocouple in the rear wall or in the furnace door

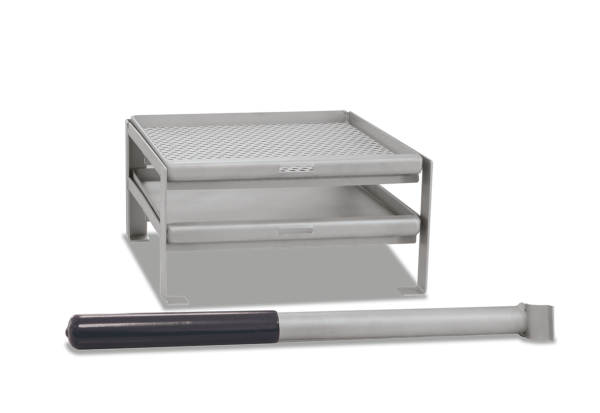

- Charging rack with closed or perforated trays for loading the furnace in two levels incl. holder for inserting/removing the trays up to a max. temperature of 800 °C and a max. loading weight per layer of 2 kg for the LV(T) 9/11 respectively 3 kg for the LV(T) 15/11

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Max. loading weight of organic substances | Max. evaporation rate of organic substances | Connected | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flap door | in °C1 | w | d | h | in l | W | D | H3 | in g | g/min | in kW | connection | in kg | in min4 |

LV 3/11 | 1100 | 180 | 150 | 120 | 3 | 345 | 390 | 810 | 5 | 0.1 | 1.3 | 1-phase | 20 | 45 |

LV 5/11 | 1100 | 205 | 170 | 130 | 5 | 385 | 415 | 810 | 10 | 0.2 | 2.6 | 1-phase | 29 | 55 |

LV 9/11 | 1100 | 235 | 240 | 170 | 9 | 415 | 485 | 865 | 15 | 0.3 | 3.3 | 1-phase | 36 | 70 |

LV 15/11 | 1100 | 230 | 340 | 170 | 15 | 415 | 590 | 865 | 25 | 0.3 | 3.6 | 1-phase | 44 | 80 |

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Max. loading weight of organic substances | Max. evaporation rate of organic substances | Connected load5 | Electrical | Weight | Heating time | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lift door | in °C1 | w | d | h | in l | W | D | H3 | in g | g/min | in kW | connection | in kg | in min4 |

LVT 3/11 | 1100 | 180 | 150 | 120 | 3 | 345 | 390 | 810 | 5 | 0.1 | 1.3 | 1-phase | 20 | 45 |

LVT 5/11 | 1100 | 205 | 170 | 130 | 5 | 385 | 415 | 810 | 10 | 0.2 | 2.6 | 1-phase | 29 | 55 |

LVT 9/11 | 1100 | 235 | 240 | 170 | 9 | 415 | 485 | 865 | 15 | 0.3 | 3.3 | 1-phase | 36 | 70 |

LVT 15/11 | 1100 | 230 | 340 | 170 | 15 | 415 | 590 | 865 | 25 | 0.3 | 3.6 | 1-phase | 44 | 80 |

1Recommended working temperature for processes with longer dwell times is 1000 °C | ||||||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnaces, ovens and accessories for the laboratory can be found in our “Laboratory” catalog.