Muffle Furnaces up to 1100 °C or 1200 °C

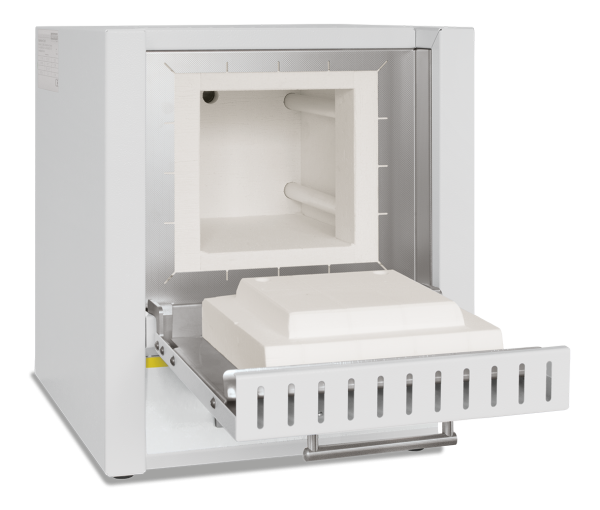

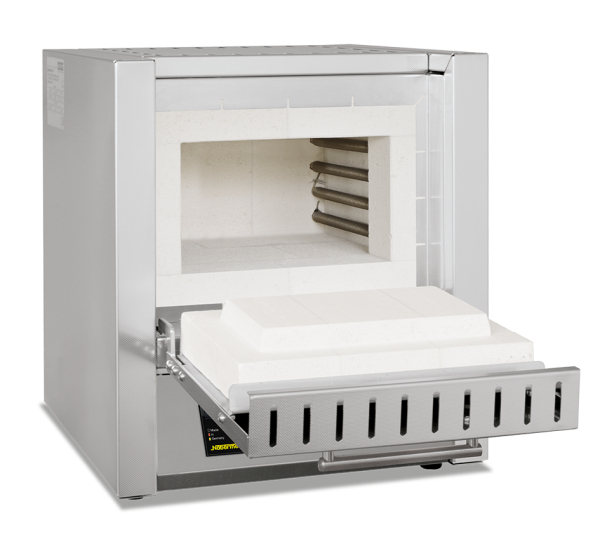

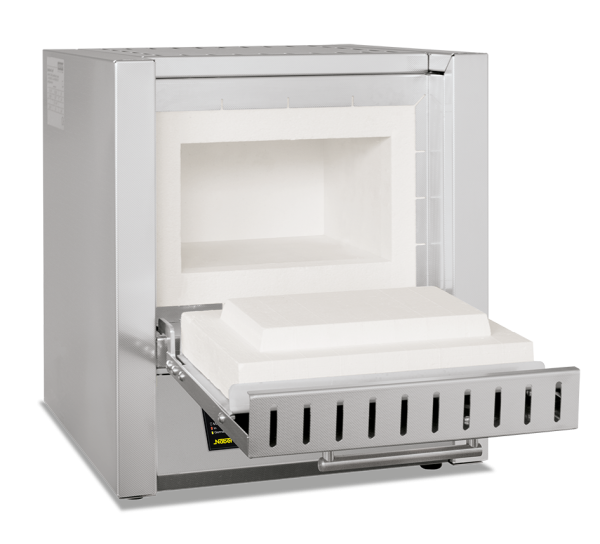

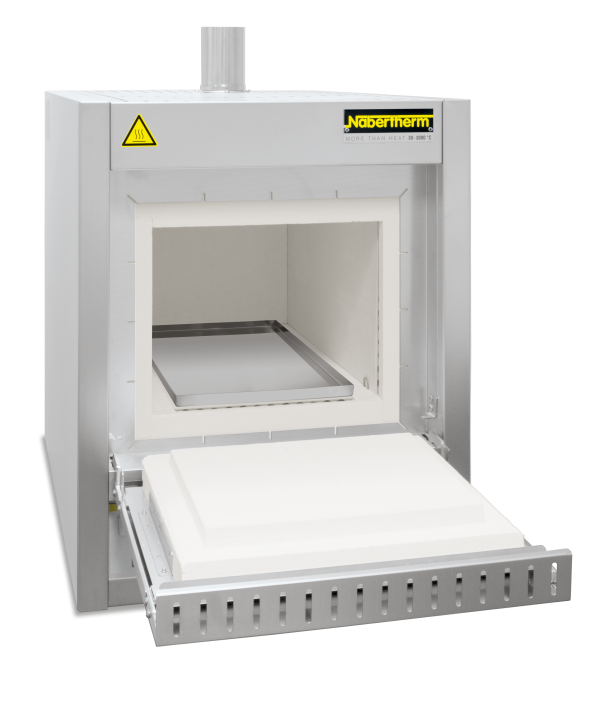

The muffle furnaces come equipped with either a flap door or lift door at no extra charge.

Function and equipment

The muffle furnaces L 3/11 - LT 60/12 have been proven for daily laboratory use. These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability. The muffle furnaces come equipped with either a flap door or lift door at no extra charge.

Standard Equipment

- Tmax 1100 °C or 1200 °C

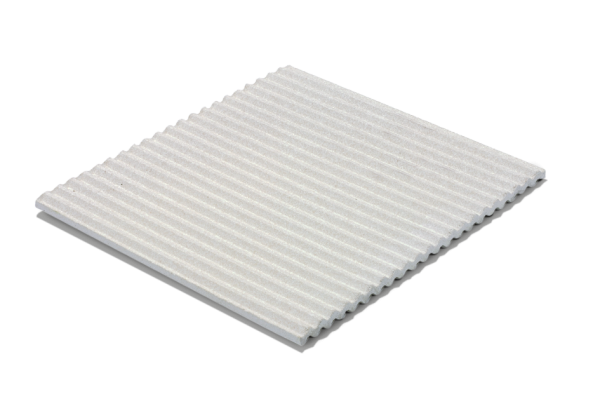

- Heating from two sides by ceramic heating plates (heating from three sides for muffle furnaces L 24/11 - LT 60/12) for an optimal temperature uniformity

- Temperature uniformity of +/− 5 K with closed fresh-air inlet in empty work space according to DIN 17052-1 at working temperatures above 800 °C

- Thermocouple type N (1100 °C) or type S (1200 °C)

- Ceramic heating plates with integral heating element which is safeguarded and easy to replace

- Optional flap door (L) which can be used as work platform or lift door (LT) with hot surface facing away from the operator

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

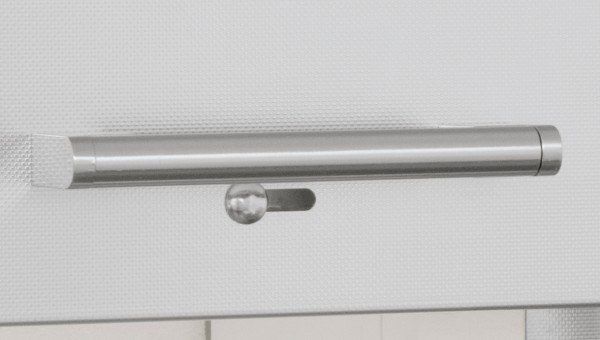

- Adjustable air inlet integrated in door (see illustration)

- Exhaust air outlet in rear wall of furnace

- Controller with touch operation B510 (5 programs with each 4 segments) resp. controller R8 for L 1/12 (adjustable for one temperature)

- Solid state relays provide for lownoise operation

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

Additional Equipment

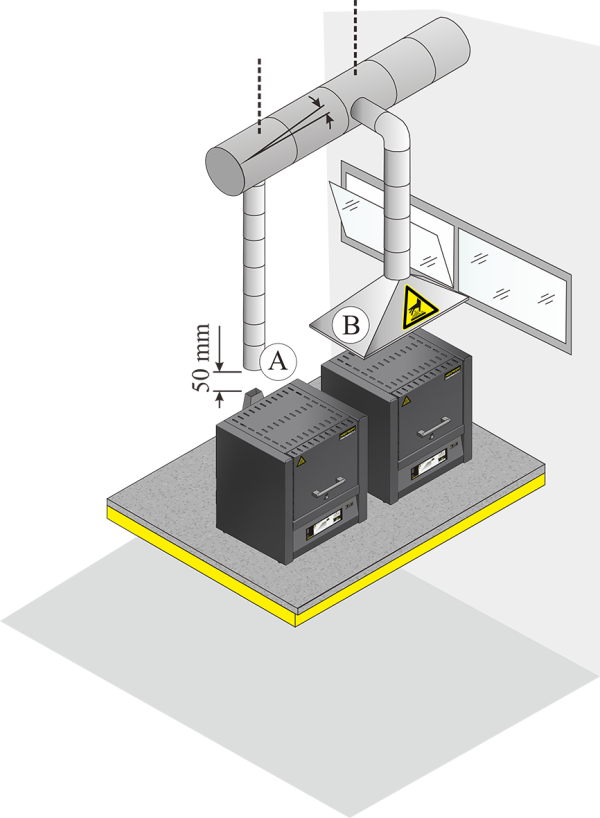

- Chimney, chimney with fan or catalytic converter (not for L 1 and L 15)

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Protective gas connection to purge with non-flammable process gases (not available in combination with chimney, chimney with fan or catalytic converter) not gas tight

- Manual or automatic gas supply system

- Port for thermocouple in the rear wall or in the furnace door

- Process control and documentation via VCD software package for monitoring, documentation and control

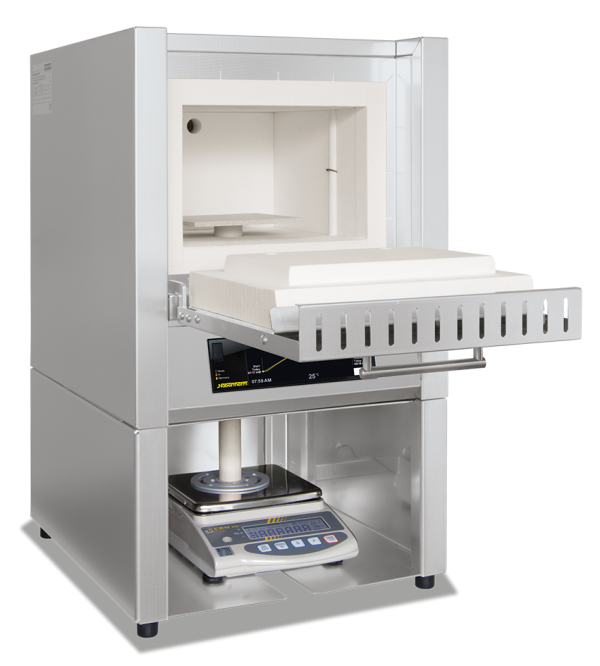

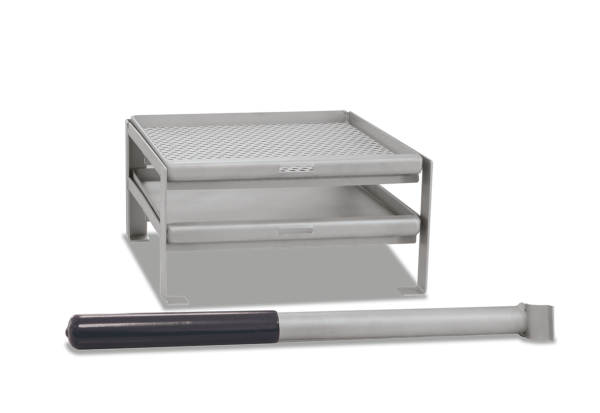

- Charging rack with closed or perforated trays for loading the furnace in two levels incl. holder for inserting/removing the trays up to a max. temperature of 800 °C and a max. loading weight per layer of 2 kg for the L(T) 9/11 respectively 3 kg for the L(T) 15/11 respectively 3,5 kg for the L(T) 24/11 and L(T) 40/11

Technical specifications

Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions2 in mm | Temperature uniformity of +/− 5K in the empty workspace5 | Connected load6 | Electrical | Weight | Heating time | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

in °C1 | w | d | h | in l | W | D | H3 | w | d | h | in kW | connection | in kg | in min4 | |

L(T) 3/11 | 1100 | 160 | 140 | 100 | 3 | 385 | 330 | 405+155 | 110 | 50 | 50 | 1.3 | 1-phase | 21 | 41 |

L(T) 5/11 | 1100 | 205 | 170 | 130 | 5 | 385 | 390 | 460+205 | 170 | 80 | 80 | 2.6 | 1-phase | 27 | 47 |

L(T) 9/11 | 1100 | 235 | 240 | 170 | 9 | 415 | 455 | 515+240 | 180 | 150 | 120 | 3.3 | 1-phase | 35 | 63 |

L(T) 15/11 | 1100 | 230 | 340 | 170 | 15 | 415 | 555 | 515+240 | 180 | 250 | 120 | 3.5 | 1-phase | 43 | 74 |

L(T) 24/11 | 1100 | 280 | 340 | 250 | 24 | 490 | 555 | 580+320 | 230 | 250 | 200 | 4.9 | 3-phase | 52 | 69 |

L(T) 40/11 | 1100 | 320 | 490 | 250 | 40 | 530 | 705 | 580+320 | 270 | 400 | 200 | 6.5 | 3-phase | 70 | 80 |

LT 60/11 | 1100 | 380 | 490 | 330 | 60 | 610 | 705 | 660+385 | 290 | 360 | 240 | 9.8 | 3-phase | 83 | 150 |

L 1/12 | 1200 | 90 | 115 | 110 | 1 | 290 | 280 | 410 | 40 | 45 | 60 | 1.6 | 1-phase | 15 | 25 |

L(T) 3/12 | 1200 | 160 | 140 | 100 | 3 | 385 | 330 | 405+155 | 110 | 50 | 50 | 1.3 | 1-phase | 21 | 48 |

L(T) 5/12 | 1200 | 205 | 170 | 130 | 5 | 385 | 390 | 460+205 | 170 | 80 | 80 | 2.6 | 1-phase | 27 | 59 |

L(T) 9/12 | 1200 | 235 | 240 | 170 | 9 | 415 | 455 | 515+240 | 180 | 150 | 120 | 3.3 | 1-phase | 35 | 78 |

L(T) 15/12 | 1200 | 230 | 340 | 170 | 15 | 415 | 555 | 515+240 | 180 | 250 | 120 | 3.5 | 1-phase | 43 | 99 |

L(T) 24/12 | 1200 | 280 | 340 | 250 | 24 | 490 | 555 | 580+320 | 230 | 250 | 200 | 4.9 | 3-phase | 52 | 82 |

L(T) 40/12 | 1200 | 320 | 490 | 250 | 40 | 530 | 705 | 580+320 | 270 | 400 | 200 | 6.5 | 3-phase | 70 | 97 |

LT 60/12 | 1200 | 380 | 490 | 330 | 60 | 610 | 705 | 660+385 | 290 | 360 | 240 | 9.8 | 3-phase | 83 | 160 |

1Recommended working temperature for processes with longer dwell times is 1000 °C (L../11) rsp. 1100 °C (L../12) | |||||||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnaces, ovens and accessories for the laboratory can be found in our “Laboratory” catalog.