There are various options for evaluation and data input the processes for optimal process documentation and data storage. The following options are suitable for data storage when using the standard controllers.

Data Storing of Nabertherm Controllers with NTLog Basic

NTLog Basic allows for recording of process data of the connected Nabertherm Controller (B500, B510, C540, C550, P570, P580) on a USB stick. The process documentation with NTLog Basic requires no additional thermocouples or sensors. Only data recorded which are available in the controller. The data stored on the USB stick (up to 130,000 data records, format CSV) can afterwards be evaluated on the PC either via NTGraph or a spreadsheet software used by the customer (e.g. Excel™ for MS Windows™). For protection against accidental data manipulation the generated data records contain checksums.

Visualization with NTGraph for MS Windows™ for Single-Zone Controlled Furnaces

The process data from NTLog can be visualized either using the customer‘s own spreadsheet program (e.g. Excel™ for MS Windows™) or NTGraph for MS WindowsTM (Freeware). With NTGraph Nabertherm provides for an additional user-friendly tool free of charge for the visualization of the data generated by NTLog. Prerequisite for its use is the installation of the program Excel™ for MS Windows™ (from version 2003). After data import presentation as diagram, table or report can be chosen. The design (color, scaling, reference labels) can be adapted by using prepared sets. NTGraph is available in eight languages (DE/EN/FR/ES/IT/CN/RU/PT). In addition, selected texts can be generated in other languages.

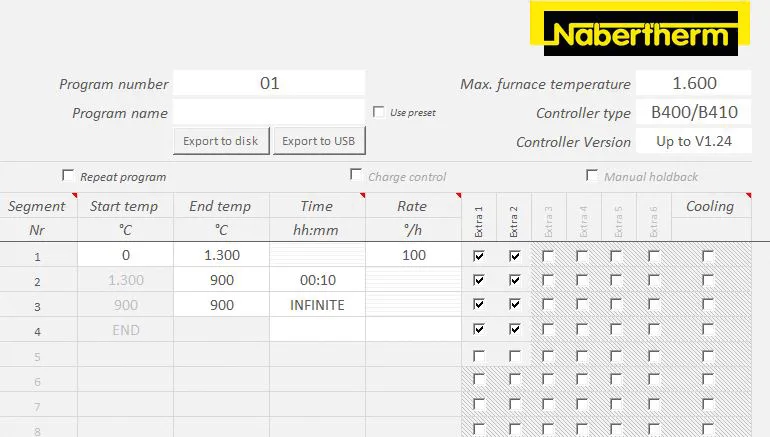

Software NTEdit for MS Windows™ for Entering Programs on the PC

By using the software NTEdit for MS Windows™ (Freeware) the input of the programs becomes clearer and thus easier. The program can be entered on customers PC and then be imported into the controller (B500, B510, C540, C550, P570, P580) with a USB stick. The display of the set curve is tabular or graphical. The program import in NTEdit is also possible. With NTEdit Nabertherm provides a user-friendly free tool. A prerequisite for the use is the client installation of Excel™ for MS Windows™ (from version 2007). NTEdit is available in eight languages (DE/EN/FR/ES/IT/CN/RU/PT).

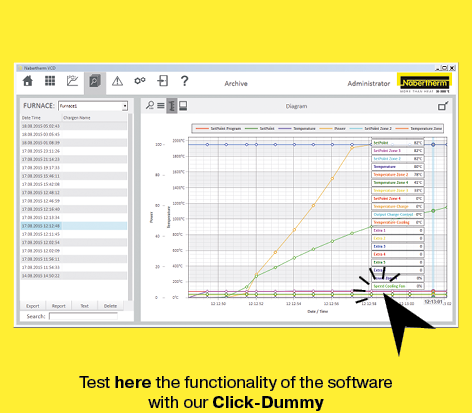

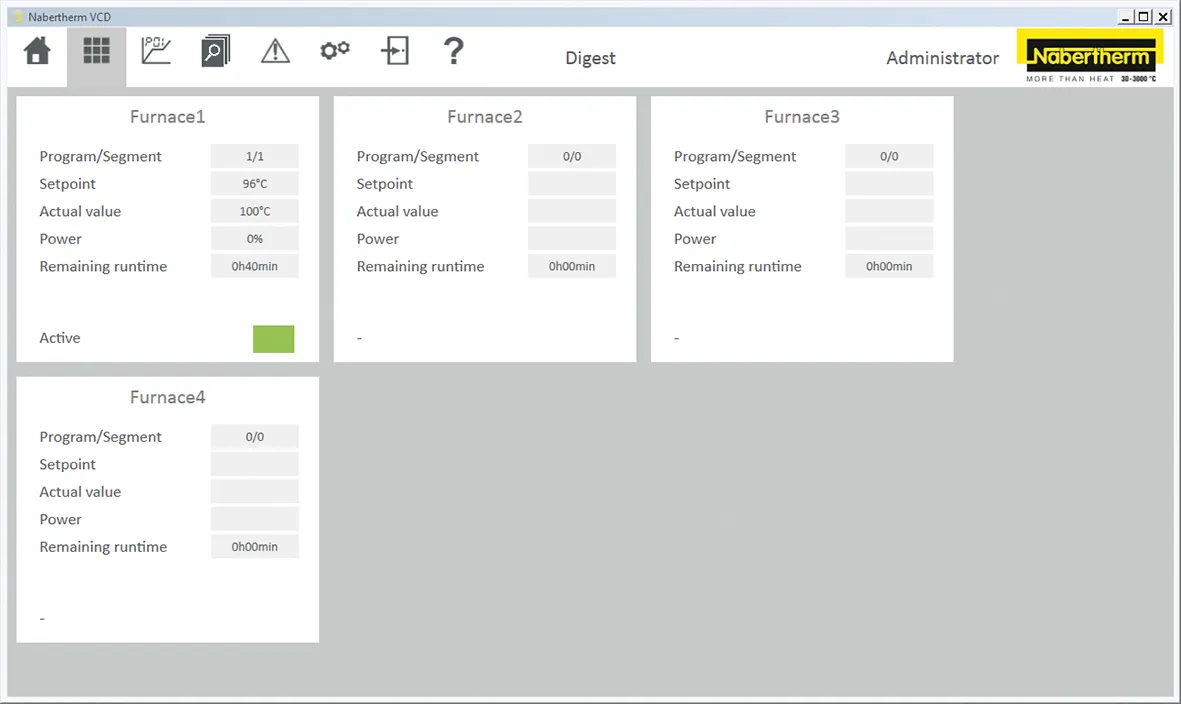

VCD-Software for Visualization, Control and Documentation

Documentation and reproducibility are more and more important for quality assurance. The powerful VCD software represents an optimal solution for single multi furnace systems as well as charg documentation on the basis of Nabertherm controllers.

The VCD software is used to record process data of the series 500 and series 400 as well as various further Nabertherm controllers. Up to 400 different heat treatment programs can be stored. The controllers are started and stopped via the software at a PC. The process is documented and archived accordingly. The data display can can be carried-out in a diagram or as data table. Even a transfer of process data to Excel™ for MS Windows™ (.csv format *) or the generation of reports in PDF format is possible.

Features

- Available for controllers series 500 - B500/B510/C540/C550/P570/P580, series 400 - B400/B410/C440/C450/P470/P480, Eurotherm 3504 and various further Nabertherm controllers

- Suitable for operating systems Microsoft Windows 7/8/10/11

- Simple installation

- Setting, Archiving and print of programs and graphics

- Operation of controllers via PC

- Archiving of process curves from up to 16 furnaces (also multi-zone controlled)

- Redundant saving of archives on a server drive

- Higher security level due to binary data storage

- Free input of charge date with comfortable search function

- Possibility to evaluate data, files exportable to Excel™ for MS Windows™

- Generation of a PDF-report

- 24 languages selectable

Extension Package 1

for Display of an Additional Temperature Measuring Point, Independant of the Furnace Controls

- Connection of an independent thermocouple, type S, N or K with temperature display on a supplied C6D display, e. g. for documentation of charge temperature

- Conversion and transmission of measured values to the VCD software

- For data evaluation, please see VCD-software features

- Display of measured temperature directly on the extension package

Extension Package 2

for the Connection of up to Three, Six or Nine Measuring Point, Independant of the Furnace Controls

- Connection of three thermocouples, tpye K, S, N or B to the included connecting box

- Possible extension of up to two or three connecting boxes with up to nine measuring points

- Conversion and transmission of measured values to the VCD software

- Data evaluation, see VCD features