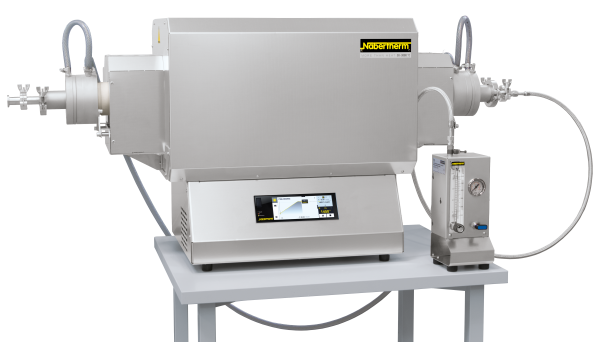

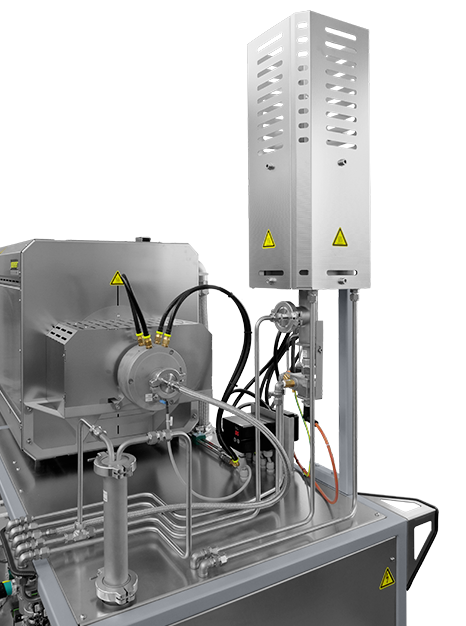

Split-Type Tube Furnaces for Horizontal or Vertical Operation up to 1300 °C

By adding different gas supply packages, you can work in a protective gas atmosphere, with gases or in a vacuum.

Function and equipment

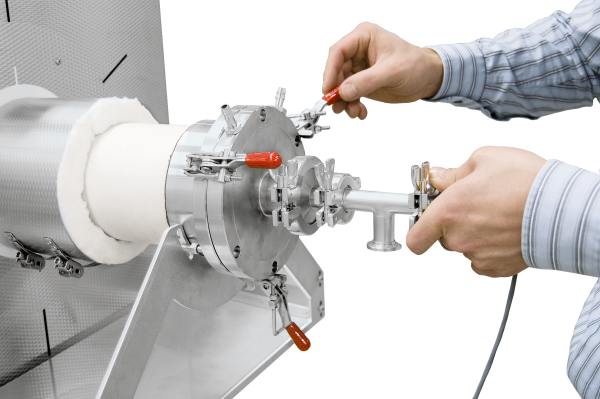

These tube furnaces can be used for horizontal (RSH) or vertical (RSV) operation. The split-type design makes it easy to change the working tube. It allows for a comfortable exchange of various working tubes (e.g. working tubes made of different materials).

Using a wide range of accessories, these professional tube furnaces can be optimally tailored for your process. By adding different gas supply packages, you can work in a protective gas atmosphere, with gases or in a vacuum. In addition to the convenient standard controllers, modern PLC controls can also be used to control the process.

Standard Equipment

- Tmax 1100 °C or 1300 °C

- Single-zoned design

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- RSV models with frame for vertical operation

- Split-type design for simple insertion of the working tube (opening temperature < 180 °C)

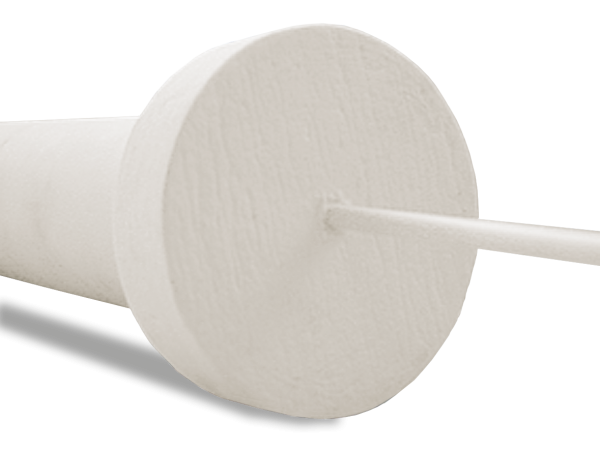

- Ceramic working tube C 530 including two fiber plugs for operation under air

- Thermocouple type N (1100 °C) or type S (1300 °C)

- Solid state relays provide for lownoise operation

- Heating elements on support tubes provide for free radiation

- RSH: switchgear and control unit integrated in furnace housing

- RSH: controller with touch operation B510 (5 programs with each 4 segments)

- RSV: switchgear and control unit separate from furnace in own wall or standing cabinet

- RSV: controller with touch operation B500 (5 programs with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Additional equipment

Additional Equipment

- Charge control with temperature measurement in the working tube

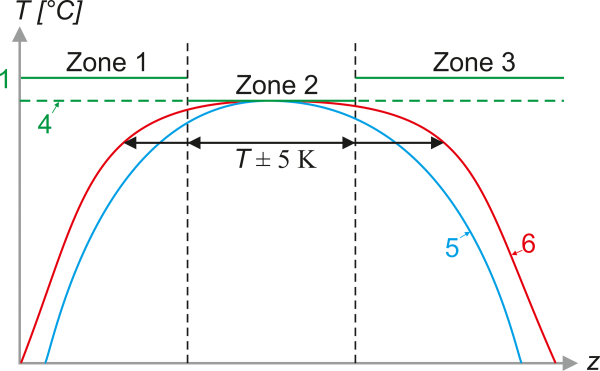

- Three-zone control for optimization of temperature uniformity

- Cooling systems for accelerated cooling of the working tube and charge

- Gas supply systems 1,15 or 2 for non-flammable process gas operation

- Gas supply package 4 for hydrogen operation

- Vacuum package to evacuate the working tube

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

| Model | Tmax1 | Outer dimensions2 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Max. connected load in kW | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in mm | in | ||||||||||||

| in °C | W3 | D | H | in mm | in mm | single zoned | three zoned | in mm | 1100 °C | 1300 °C | connection | kg | |

| RSH 50/250/.. | 420 | 385 | 510 | 50 | 250 | 80 | - | 450 | 1.9 | 1.9 | 1-phase | 25 | |

| RSH 50/500/.. | 670 | 385 | 510 | 50 | 500 | 170 | 250 | 700 | 3.4 | 3.4 | 1-phase4 | 36 | |

| RSH 80/500/.. | 670 | 450 | 580 | 80 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase4 | 46 | |

| RSH 80/750/.. | 920 | 500 | 920 | 80 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 | |

| RSH 80/1000/.. | 1100 | 1170 | 500 | 920 | 80 | 1000 | 330 | 500 | 13.7 | 13.7 | 3-phase4 | 91 | |

| RSH 120/500/.. | or | 670 | 450 | 580 | 120 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase4 | 46 |

| RSH 120/750/.. | 1300 | 920 | 500 | 920 | 120 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 |

| RSH 120/1000/.. | 1170 | 500 | 920 | 120 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase4 | 91 | |

| RSH 170/750/.. | 920 | 500 | 920 | 170 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 | |

| RSH 170/1000/.. | 1170 | 500 | 920 | 170 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase4 | 91 | |

| RSV 50/250/.. | 410 | 585 | 975 | 50 | 250 | 80 | - | 450 | 1.9 | 1.9 | 1-phase | 25 | |

| RSV 50/500/.. | 410 | 585 | 1225 | 50 | 500 | 170 | 250 | 700 | 3.4 | 3.4 | 3-phase4 | 36 | |

| RSV 80/500/.. | 480 | 585 | 1225 | 80 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase4 | 46 | |

| RSV 80/750/.. | 540 | 635 | 1480 | 80 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 | |

| RSV 80/1000/.. | 1100 | 540 | 635 | 1730 | 80 | 1000 | 330 | 500 | 13.7 | 13.7 | 3-phase4 | 91 | |

| RSV 120/500/.. | or | 480 | 585 | 1225 | 120 | 500 | 170 | 250 | 850 | 6.6 | 6.6 | 3-phase4 | 46 |

| RSV 120/750/.. | 1300 | 540 | 635 | 1480 | 120 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 |

| RSV 120/1000/.. | 540 | 635 | 1730 | 120 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase4 | 91 | |

| RSV 170/750/.. | 540 | 635 | 1480 | 170 | 750 | 250 | 375 | 1100 | 10.6 | 12.0 | 3-phase4 | 76 | |

| RSV 170/1000/.. | 540 | 635 | 1730 | 170 | 1000 | 330 | 500 | 1350 | 13.7 | 13.7 | 3-phase4 | 91 | |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K 2External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 3Without tube 4At 3-phase execution an N conductor ist required (3/N/PE) | |||||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of furnaces, ovens and accessories for the laboratory can be found in our “Laboratory” catalog.