High-Temperature Tube Furnaces for Horizontal or Vertical Operation up to 1800 °C

By using different gas supply systems, operations can be performed under non-flammable or flammable protective or reactive gases or under vacuum.

Function and equipment

Tube furnace RHTV 50/150/17 with stand and gas supply system 2

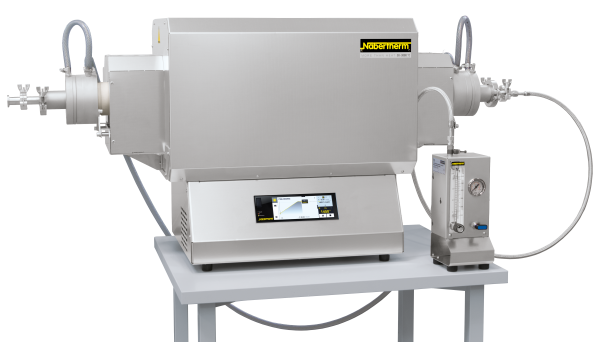

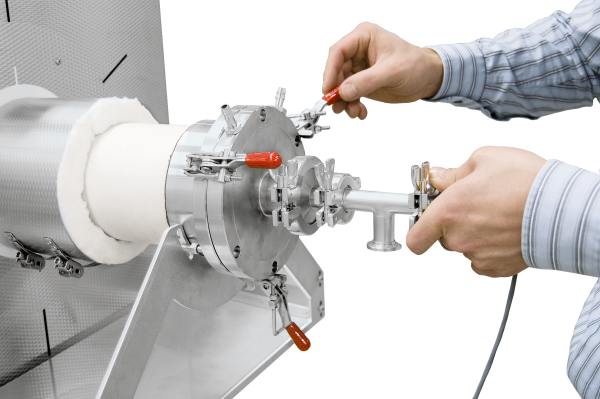

RHTH 80/300/18 tube furnace with water-cooled flanges and charge control

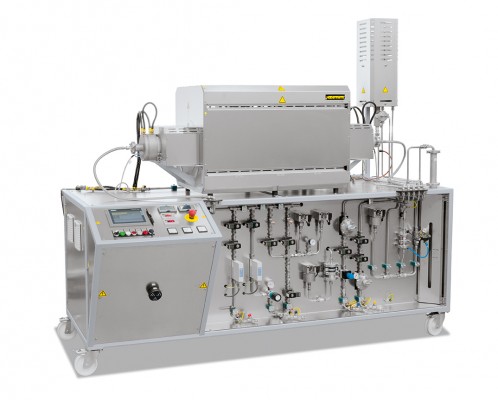

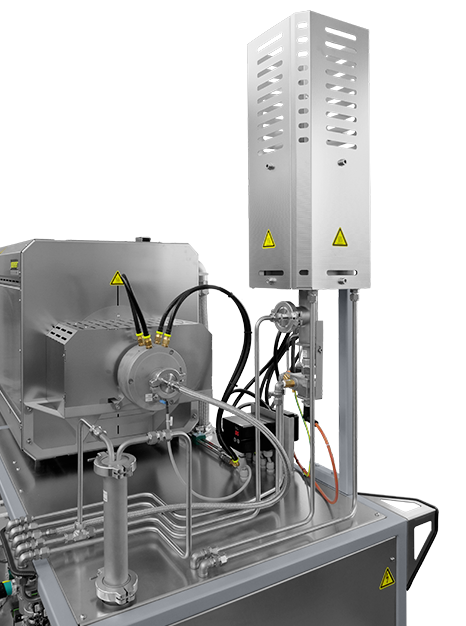

RHTH 120/600/18 with gas supply system 4 for operation with hydrogen

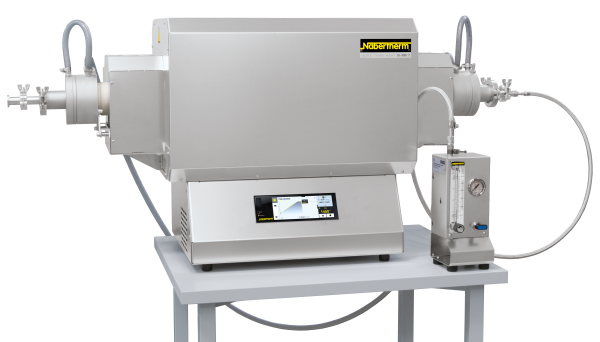

Tube furnace RHTH 120/600/17

Sintering under hydrogen in a tube furnace of RHTH product line

Example of over-temperature limiter

The high-temperature tube furnaces are available in either horizontal (type RHTH) or vertical (type RHTV) designs. High-quality insulation materials made of vacuum-formed fiber plates enable energy-saving operation due to low heat storage and heat conductivity. By using different gas supply systems, operations can be performed under non-flammable or flammable protective or reactive gases or under vacuum.

Standard Equipment

- Tmax 1600 °C, 1700 °C, or 1800 °C

- Single-zoned design

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Insulation with vacuum-formed ceramic fiber plates

- Tube furnaces RHTV with frame for vertical operation

- Type B thermocouple

- Solid state relays provide for lownoise operation

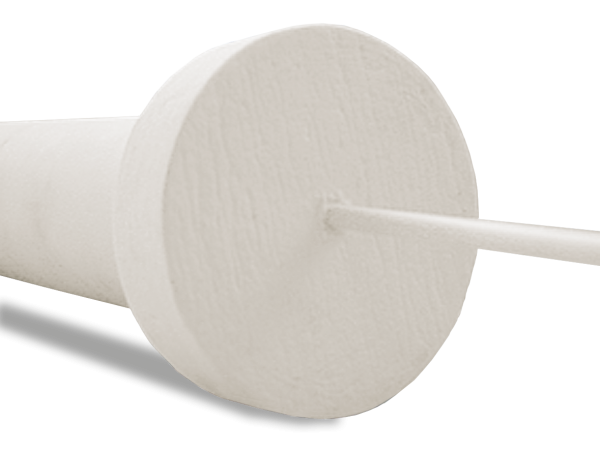

- Ceramic working tube C 799 including two fiber plugs for operation under air

- Hanging and easy to change MoSi2 heating elements

- Power unit with low-voltage transformer and thyristor

- Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

- Switchgear and control unit separate from furnace in separate floor standing cabinet

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P570 (50 programs with each 40 segments)

Additional equipment

Additional Equipment

- Charge control with temperature measurement in the working tube

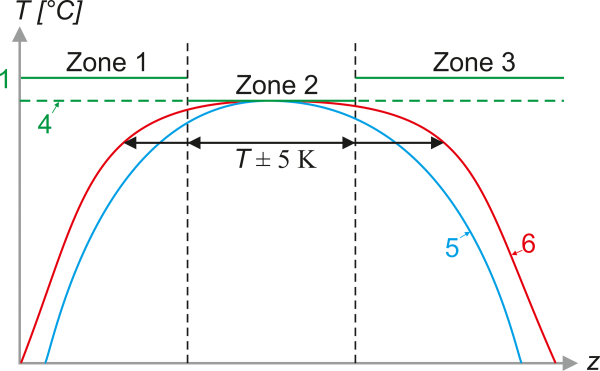

- Three-zone control for optimization of temperature uniformity (only horizontal tube furnaces RHTH)

- Gas supply system 2 for non-flammable process gas

- Gas supply system 4 for hydrogen operation

- Vacuum package to evacuate the working tube

- Process control and documentation via VCD software package for monitoring, documentation and control

Technical specifications

| Model Horizontal design | Tmax1 | Outer dimensions3 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Connected load5 | Electrical | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in mm | ||||||||||||

| in °C | W2 | D | H | in mm | in mm | single zoned | three zoned | in mm | in kW | connection | in kg | |

| RHTH 50/150/.. | 1600 or | 530 | 480 | 640 | 50 | 150 | 50 | 70 | 380 | 5.8 | 3-phase4 | 70 |

| RHTH 80/300/.. | 1700 or | 680 | 550 | 640 | 80 | 300 | 100 | 150 | 530 | 9.4 | 3-phase4 | 90 |

| RHTH 120/600/.. | 1800 | 980 | 550 | 640 | 120 | 600 | 200 | 300 | 830 | 14.8 | 3-phase4 | 110 |

| Model | Tmax1 | Outer dimensions3 in mm | Max. outer tube Ø | Heated length | Length constant temperature1 +/− 5 K | Tube length | Connected load5 | Electrical | Weight | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Vertical design | in °C | W | D | H2 | in mm | in mm | in mm | in mm | in kW | connection | in kg |

| RHTV 50/150/.. | 1600 or | 610 | 700 | 1130 | 50 | 150 | 30 | 380 | 5.8 | 3-phase4 | 70 |

| RHTV 80/300/.. | 1700 or | 680 | 700 | 1280 | 80 | 300 | 80 | 530 | 10.7 | 3-phase4 | 90 |

| RHTV 120/600/.. | 1800 | 680 | 700 | 1580 | 120 | 600 | 170 | 830 | 19.4 | 3-phase4 | 110 |

| 1Values outside the tube. Difference to temperature inside the tube up to + 50 K 2Without tube 3External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 4Heating only between two phases 5The connected load refers to the standard furnace and may increase for a furnace with additional equipment. For furnaces with connection options for multi-range voltages, the connected load applies to the highest permissible connected voltage. | |||||||||||

Request for quotation

Archivo de vídeo

Further products

Catalog

A complete overview of our extensive range of furnaces, ovens and accessories for the laboratory can be found in our “Laboratory” catalog.