Function and equipment

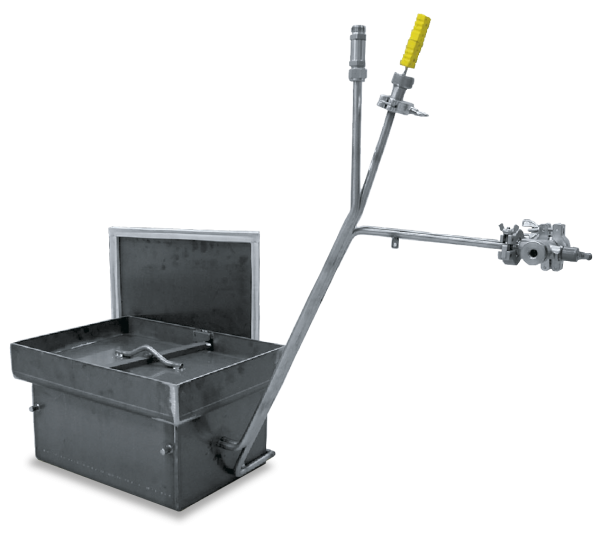

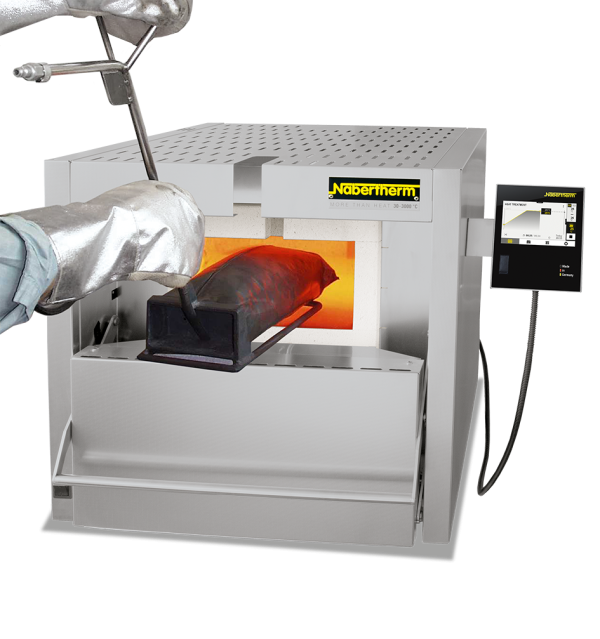

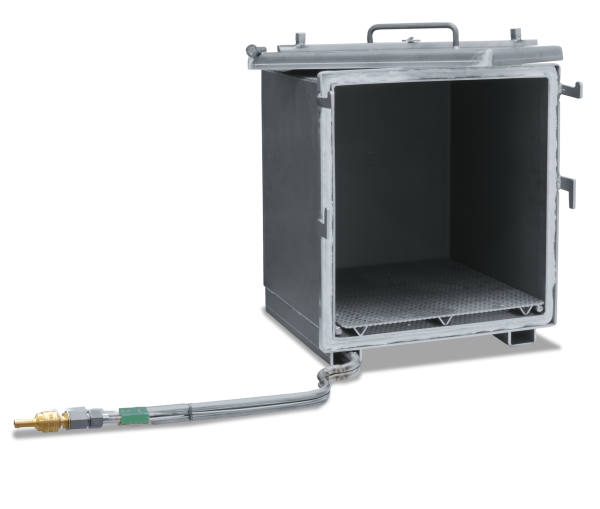

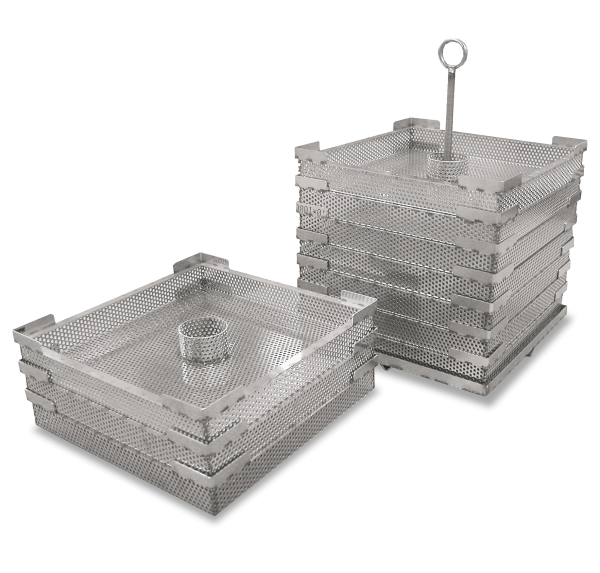

Working with Annealing Boxes

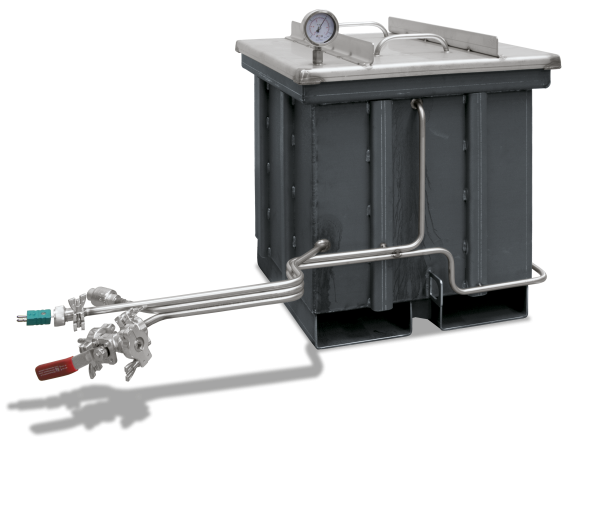

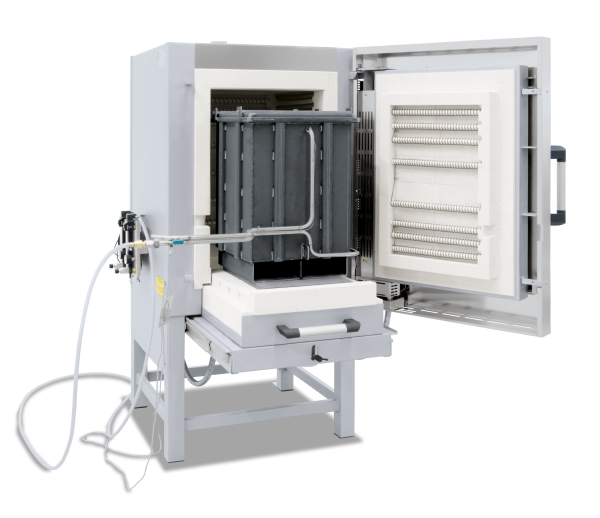

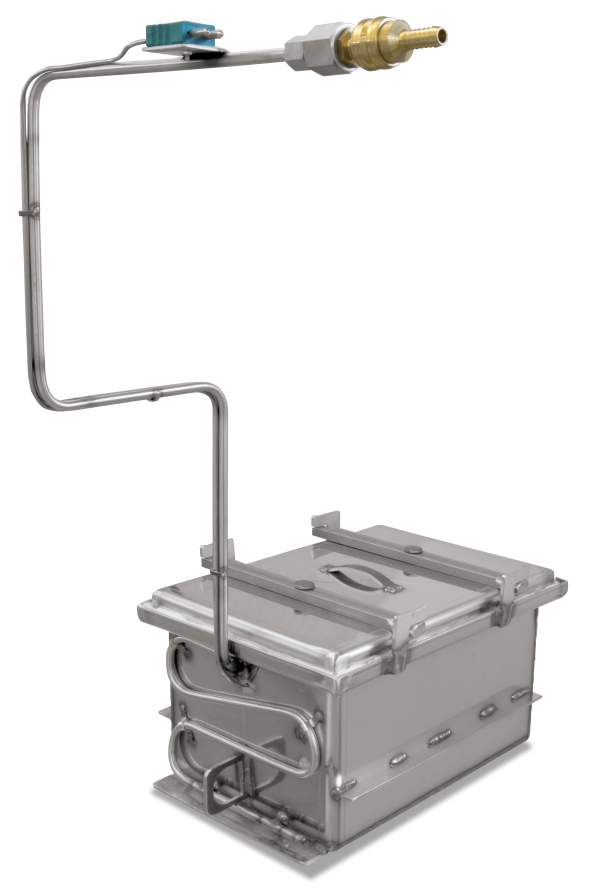

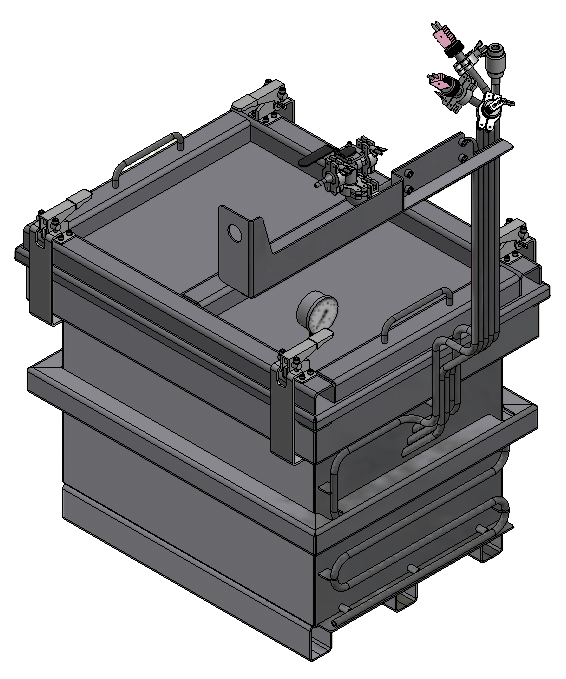

Annealing boxes are made of heat-resistant alloy 314 (AISI)/(DIN material no. 1.4841) and also feature a lid for top charging. A ceramic fiber gasket is inserted in the circular seal profile on the upper edge of the box to seal it. To prevent oxidation during the process, neutral annealing coal is placed in the box. These bind the oxygen in the box. The oxygen inside the box is bound by the coal. After the heat treatment, the box is removed from the oven, the lid is opened using tongs and the workpiece removed. Our annealing boxes are also well suited for brazing. The boxes can also be used with the appropriate granulate for carburizing (also referred to as case hardening or cementing) and for powder nitriding or powder boriding. The workpieces are placed in the box with carburizing granulate or nitriding powder or boriding powder and a suitable activator.

- Tmax 1100 °C

- Annealing box with lid and seal profile

- Lid sealing with ceramic fiber

- Also usable for carburizing and powder nitriding

- Heat-resistant alloy 314 (AISI)/(DIN material no. 1.4841)

Technical specifications

| Article no. | Furnace | Inner dimensions in mm | Outer dimensions in mm | Charging method | ||||

|---|---|---|---|---|---|---|---|---|

| w | d | h | W | D | H | of the box | ||

| 631000962 | N 7/H | 180 | 190 | 90 | 216 | 226 | 116 | charging fork |

| 631000967 | N 11/H, N 11/HR | 180 | 290 | 90 | 216 | 326 | 116 | charging fork |

| 631000972 | N 17/HR | 180 | 440 | 90 | 216 | 476 | 116 | charging fork |

| 631000977 | N 31/H | 280 | 230 | 200 | 316 | 304 | 226 | draw hook |

| 631000982 | N 41/H | 280 | 380 | 200 | 316 | 454 | 226 | draw hook |

| 631000986 | N 61/H, N 87/H | 280 | 500 | 200 | 316 | 574 | 226 | draw hook |

| Article no. 601655055, 1 set of fiber insulation cord, 5 strips of 610 mm each Work space = box inner dimensions: - 30 mm to all sides Larger boxes and custom dimensions available upon request | ||||||||

Request for quotation

Further products

Catalog

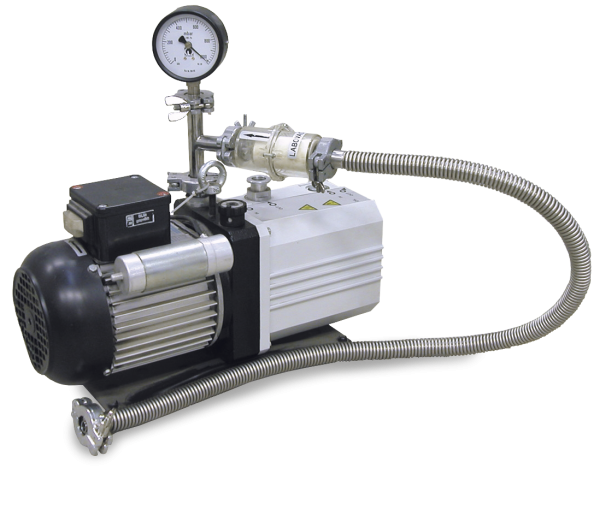

A complete overview of our extensive range of furnaces and accessories for various processes that take place under flammable or non-flammable reaction gases, in a salt bath or under vacuum can be found in our catalog "Thermal Process Technology 2".