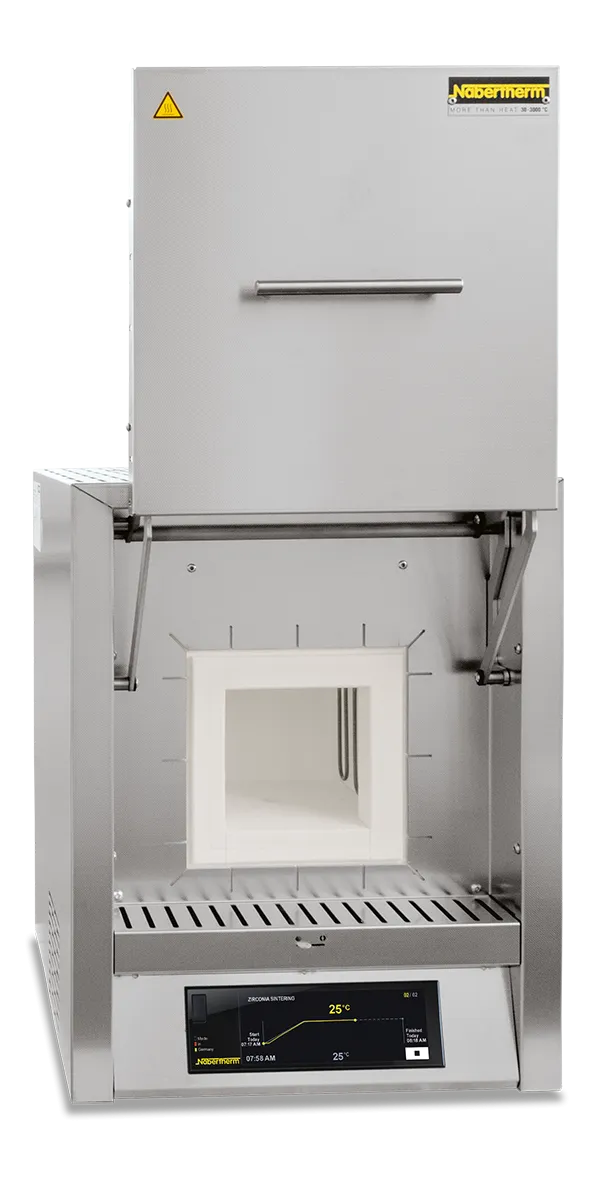

High-Temperature Furnaces with SiC Rod Heating and Fiber Insulation up to 1550 °C

Heating from both sides via vertically mounted SiC rods.

Function and equipment

The high-temperature furnaces HTC 16/16 - HTC 450/16 are heated by vertically hung SiC rods, which makes them especially suitable for sintering processes up to a maximum operating temperature of 1500 °C. For some processes, e. g. for sintering zirconium oxide, the reduction of interactivity between the charge and the SiC rods, these models are more suitable than the alternatives heated with molybdenum disilicide elements. The basic construction of these furnaces make them comparable with the already familiar models in the HT product line and they can be upgraded with the same additional equipment.

- Tmax 1550 °C

- Recommended maximum working temperature approx. 50 °C below Tmax of the furnace. Higher working temperatures will increase wear and tear.

- Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

- Heating from both sides via vertically mounted SiC rods

- High-quality fiber insulation backed by special insulation

- Long-life roof insulation with special suspension

- Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

- Temperature uniformity at 1450 °C up to +/− 6 °C according to DIN 17052-1

- Chain-guided parallel swivel door for defined opening and closing of the door without destroying the insulation

- Two-door design (front/back) for high-temperature furnaces > HTC 276/..

- Labyrinth sealing ensures the least possible temperature loss in the door area

- Reinforced floor as protection for fiber insulation and to load heavy weights

- Vapor vent in the furnace roof with motorized exhaust air flaps

- Stainless steel exhaust hood as interface to customer’s exhaust system

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

- Controller with touch operation P570 (50 programs with each 40 segments)

Additional equipment

- Cooling system to cool the furnace with a defined temperature gradient or with a preset fresh air volume. Both operating modes can be switched on and off for different segments by means of the extra function of the controller.

- Thermocouple inlet with screw cap

- Thermocouple for the heating control with calibration certificate

- Protective gas connection to purge with non-flammable process gases (not completely gas-tight)

- Automatic gas supply system with solenoid valve and rotameter, controlled by the extra function of the controller

- Refractory brick floor insulation for a higher floor load (Tmax 1700 °C)

- Lift door

- Automatic door lock incl. door contact switch

- Heating elements protected against mechanical damage

- Special heating element qualities e. g. for zircon oxide applications

- Ethernet interface

Technical specifications

| Model | Tmax | Inner dimensions in mm | Volume | Outer dimensions1 in mm | Heating Power | Connected | Electrical | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| in°C | w | d | h | in l | W | D | H | in kW | load3 in kW | connection | in kg | |

| HTC 16/16 | 1550 | 200 | 300 | 260 | 16 | 820 | 690 | 1860 | 12.0 | 16.5 | 3-phase2 | 220 |

| HTC 40/16 | 1550 | 300 | 350 | 350 | 40 | 1010 | 800 | 1990 | 12.0 | 16.5 | 3-phase | 420 |

| HTC 64/16 | 1550 | 400 | 400 | 400 | 64 | 1140 | 890 | 2040 | 18.0 | 41.5 | 3-phase | 660 |

| HTC 128/16 | 1550 | 400 | 800 | 400 | 128 | 1140 | 1280 | 2040 | 26.0 | 61.0 | 3-phase | 550 |

| HTC 160/16 | 1550 | 500 | 550 | 550 | 160 | 1250 | 1040 | 2260 | 21.0 | 40.0 | 3-phase | 535 |

| HTC 276/16 | 1550 | 500 | 1000 | 550 | 276 | 1340 | 1600 | 2290 | 36.0 | 73.0 | 3-phase | 1300 |

| HTC 450/16 | 1550 | 500 | 1150 | 780 | 450 | 1380 | 1820 | 2570 | 64.0 | 118.0 | 3-phase | 1450 |

| 1External dimensions vary when furnace is equipped with additional equipment. Dimensions on request. 2Heating only between two phases 3The connected load refers to the standard furnace and may increase for a furnace with additional equipment. For furnaces with connection options for multi-range voltages, the connected load applies to the highest permissible connected voltage. | ||||||||||||

Request for quotation

Further products

Catalog

A complete overview of our extensive range of bogie hearth furnaces, hood furnaces, glass melting furnaces and other models for your glass processing can be found in our catalog “Fiber Optics/Glass”.